In the ABB PLC control system, the SPBRC400 rack is not an independent control unit, but exists as a "hardware platform hub", with its core role reflected in the following three dimensions:

1. Module bearing and physical fixation: Provide standardized slot interfaces for installing various functional modules such as CPU modules, I/O modules, communication modules, power modules, etc., ensuring stable connection of modules in the vibration and impact environment of industrial sites, and avoiding control failures caused by physical looseness.

2. System bus and signal interaction: The internal integration of high-speed backplane bus enables real-time data transmission between modules. The CPU module reads the field signals of the I/O module through the backplane bus and sends control instructions to the execution module to ensure fast response of the control logic. The bus transmission delay is usually controlled at the millisecond level to meet the real-time control requirements of industry.

3. Power distribution and safety guarantee: Cooperate with the special power module to stably distribute the input power to all modules on the rack. At the same time, it has over-current and over-voltage protection mechanisms. When a module has an abnormal power supply, it can effectively isolate the fault and avoid affecting the normal operation of the whole system.

ABB SPBRC400 PLC module/rack

Basic positioning and core role

In the ABB PLC control system, the SPBRC400 rack is not an independent control unit, but exists as a "hardware platform hub", with its core role reflected in the following three dimensions:

1. Module bearing and physical fixation: Provide standardized slot interfaces for installing various functional modules such as CPU modules, I/O modules, communication modules, power modules, etc., ensuring stable connection of modules in the vibration and impact environment of industrial sites, and avoiding control failures caused by physical looseness.

2. System bus and signal interaction: The internal integration of high-speed backplane bus enables real-time data transmission between modules. The CPU module reads the field signals of the I/O module through the backplane bus and sends control instructions to the execution module to ensure fast response of the control logic. The bus transmission delay is usually controlled at the millisecond level to meet the real-time control requirements of industry.

3. Power distribution and safety guarantee: Cooperate with the special power module to stably distribute the input power to all modules on the rack. At the same time, it has over-current and over-voltage protection mechanisms. When a module has an abnormal power supply, it can effectively isolate the fault and avoid affecting the normal operation of the whole system.

Core functional features

The SPBRC400 rack is based on industrial design standards, combined with ABB's technical accumulation in the field of automation, and has the following outstanding functional characteristics:

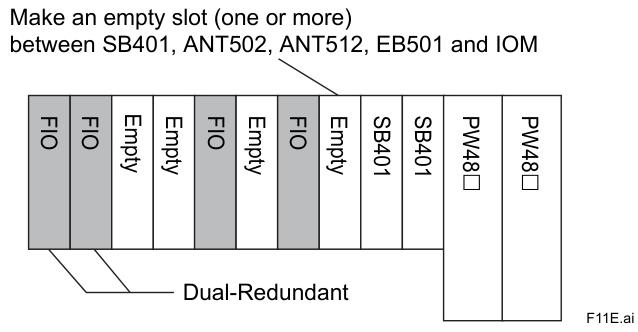

-High compatibility expansion: usually equipped with multiple standardized slots (the specific number varies slightly depending on the model, commonly 4-8 slots), compatible with various modules such as digital I/O, analog I/O, temperature acquisition, pulse output, etc. of ABB's same series, supporting users to flexibly configure the system according to control needs and achieve on-demand expansion of functions.

-Stable signal transmission: By using differential signal transmission technology to optimize the backplane bus, it effectively resists electromagnetic interference (EMI) and radio frequency interference (RFI) in industrial sites, ensuring the accuracy and completeness of data transmission in complex electromagnetic environments such as motor start stop and high-voltage equipment operation.

-Convenient installation and maintenance: The module is installed using a snap on or screw fixed method, with easy module insertion and removal, making it convenient for quick on-site replacement and maintenance; The surface design of the rack has clear slot numbers and module identification, reducing the difficulty of operation during wiring and debugging.

-Industrial grade environmental adaptability: The body is made of high-strength metal material, with good heat dissipation performance and structural stability. The working temperature range usually covers -20 ℃~60 ℃, and the humidity adaptability range is 5%~95% (no condensation), which can adapt to harsh industrial site environments such as metallurgy, chemical industry, and power.

Key technical parameters

Number of slots

Usually 4/6/8 (depending on the model)

Support the combination installation of CPU and various functional modules

Backplane bus speed

Up to 100Mbps

Meet the concurrent data transmission requirements of multiple modules

working power supply

DC 24V ±10%

Provided by the matching power module, supporting wide voltage input

power loss

≤ 5W (unloaded), fully loaded depending on module configuration

Low power design to reduce system heat generation

Operating Temperature

-20℃ ~ 60℃

Adapt to high and low temperature industrial environments

Protection level

IP20 (panel installation status)

Prevent solid foreign objects from entering, suitable for installation inside control cabinets

Installation method

DIN rail installation/panel installation

Meets the standardized installation requirements of industrial control cabinets

Applicable industries and typical application scenarios

The SPBRC400 rack is widely used in various industrial automation control scenarios due to its high stability, strong adaptability, and flexible scalability. The core applicable industries and applications are as follows:

1. Metallurgical industry: Used for blast furnace coal injection control, converter oxygen supply regulation, steel rolling production line speed synchronization control and other systems in steel production, carrying the collection and control instruction execution of temperature, pressure, liquid level and other signals, ensuring the continuity and stability of metallurgical processes.

2. Chemical industry: Suitable for temperature, pressure, and flow closed-loop control of chemical reaction vessels, as well as start stop logic control of chemical raw material transfer pumps. In flammable and explosive chemical environments, stable module connections and signal transmission ensure the safety and controllability of the production process.

3. Power industry: Applied to auxiliary control systems in substations, feed pump control in thermal power plants, photovoltaic/wind power regulation systems in new energy power plants, to achieve status monitoring and precise control of electrical equipment, and improve the operational efficiency of the power system.

4. Manufacturing industry: As the core frame of equipment linkage control in automotive parts production lines and mechanical processing assembly lines, it connects sensors, actuators and other equipment to achieve automated connection between processes, improve production efficiency and product qualification rate.

5. Water treatment industry: Used for dissolved oxygen control in aeration tanks, automatic adjustment of dosing systems, and rotation control of water pump units in sewage treatment plants. Through stable I/O signal interaction, it ensures the standard operation of water treatment processes.

Precautions for use

To ensure the long-term stable operation of the SPBRC400 rack and the entire PLC system, the following precautions should be taken during installation, commissioning, and maintenance:

-Installation environment specifications: The rack should be installed in a well ventilated control cabinet without direct sunlight, avoiding direct proximity to high-temperature equipment such as heaters and frequency converters. The control cabinet should be equipped with a cooling fan or air conditioner to ensure that the ambient temperature does not exceed the maximum working temperature of the rack.

-Module installation specifications: Before installing the module, the rack power must be cut off. When inserting the module, it should be aligned with the slot guide rail and slowly pushed in until the buckle is locked, to avoid violent insertion and removal that may cause the slot pins to bend or be damaged; The CPU module usually needs to be installed in the designated slot of the rack (usually the first slot) to ensure normal bus communication.

-Power connection specifications: ABB recommended matching power modules must be used, and the power wiring must be firm and reliable, distinguishing positive and negative poles to avoid reverse connection; The grounding terminal of the rack should be reliably connected to the industrial grounding system, and the grounding resistance should be less than 4 Ω to enhance the anti-interference ability of the system.

-Daily maintenance points: Regularly clean the dust on the surface of the rack and inside the slots to avoid dust accumulation that may cause poor contact or poor heat dissipation; Regularly check the status of the module's indicator lights, determine the system's operating status through indicator lights (such as power lights and communication lights), and promptly troubleshoot any abnormalities found.

-Attention to expansion and upgrade: When expanding modules, it is necessary to confirm the compatibility between the module and the rack, and backup the PLC program before adding new modules; When upgrading the system, it is necessary to follow ABB's official upgrade process to avoid system failures caused by mismatched firmware versions.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-