Rolls-Royce UN81 - STBD WING PANEL 000127612

The Rolls-Royce UN81 stands out as a premier automation solution designed specifically for demanding environments in the power industry, petrochemical sector, and general automation applications. Renowned for its robust architecture and advanced input/output capabilities, the UN81 provides unparalleled control precision and operational reliability, making it a cornerstone component in complex automation systems. At the core of the Rolls-Royce UN81 is its impressive input/output capacity, supporting up to 128 digital inputs and 96 digital outputs, alongside versatile analog I/O channels. This extensive I/O range allows seamless integration with various sensors, actuators, and control elements, ensuring comprehensive monitoring and management of industrial processes. The unit’s durability is engineered to withstand harsh conditions commonly encountered in power plants and petrochemical facilities—with an operating temperature range from -40°C to 70°C, resistance to vibration, and robust electromagnetic compatibility (EMC) compliance. These features guarantee uninterrupted performance even in extreme environments, minimizing downtime and maintenance costs. Performance metrics of the UN81 emphasize fast processing speeds with real-time data handling capabilities, enabling rapid response to changing process conditions.

The system’s embedded microcontroller architecture ensures low latency in control loops, which is essential for applications requiring high precision and safety compliance. Additionally, the UN81 supports multiple communication protocols, including CANbus, Modbus, and Ethernet interfaces, facilitating easy integration within existing automation networks and compatibility with supervisory control and data acquisition (SCADA) systems. In real-world scenarios, the Rolls-Royce UN81 excels in applications such as turbine control in power generation plants, where precise regulation of fuel flow and rotational speed is critical for efficiency and emissions control. Similarly, in petrochemical plants, the UN81’s robust I/O and communication capabilities enable it to manage complex process automation tasks such as pressure and temperature monitoring, valve actuation, and emergency shutdown systems. Its flexibility and reliability also make it an excellent choice for general automation tasks in manufacturing and infrastructure projects, where real-time control and safety are paramount. When compared to other Rolls-Royce automation products like the Rolls-Royce UN 926 and Rolls-Royce UN925, the UN81 offers a more balanced combination of I/O density and processing power, optimized for mid-to-large scale automation systems.

While the UN 926 may cater to high-capacity input/output scenarios and the UN925 focuses on compact control solutions, the UN81 fills the niche for applications requiring both extensive I/O and high durability. Moreover, unlike the Rolls-Royce Remote Control System Node, which is primarily designed for remote command and monitoring, the UN81 offers direct control with enhanced processing capabilities, enabling it to act as the central automation hub. Alongside the Rolls-Royce UN81, complementary products such as the Rolls-Royce Panel Control and Rolls-Royce CE05-00 provide user interface and control panel solutions that enhance operator interaction and system monitoring. The Rolls-Royce MPC-210 and MPC-300-A7029099 modules serve as excellent expansion units for scaling the automation system, while the Rolls-Royce CANMAN CCN-01 and CANMAN CCN-11 facilitate robust communication management within complex control networks. Additionally, the Rolls-Royce CMS-X and Rolls-Royce AQM series offer advanced condition monitoring and quality management features that integrate seamlessly with the UN81 platform, enhancing preventive maintenance and operational efficiency.

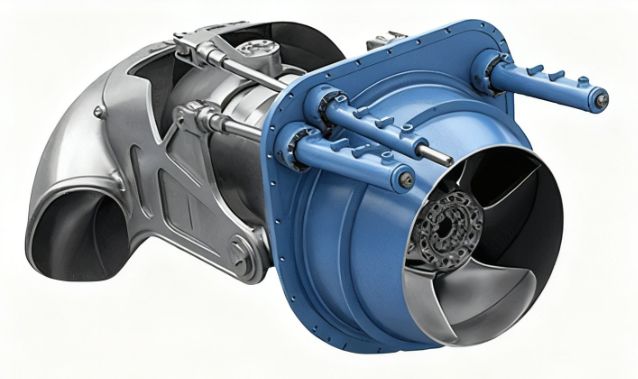

The application of UN81 in power industry, petrochemical, and general automation is further supported by Rolls-Royce’s extensive portfolio of automation products, including the Rolls-Royce F120C for fuel control and the Rolls-Royce Brown Thruster for dynamic positioning in marine environments. The UN81’s adaptability ensures it complements these specialized systems by providing reliable, centralized automation control capable of interfacing with diverse equipment and protocols. In summary, the Rolls-Royce UN81 is a versatile, high-performance automation controller designed to meet the rigorous demands of modern industrial applications. Its substantial input/output capacity, rugged construction, and fast processing speed position it as a leading solution in power generation, petrochemical processing, and general automation tasks. Combined with related Rolls-Royce automation products such as the UN925, Panel Control, MPC-210, CANMAN CCN-01, and CMS-X, the UN81 delivers a comprehensive, integrated control architecture that enhances operational efficiency, safety, and reliability across a broad spectrum of industries. As part of the renowned Rolls-Royce automation products family, the UN81 represents a trusted choice for engineers seeking dependable performance and seamless system integration.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-