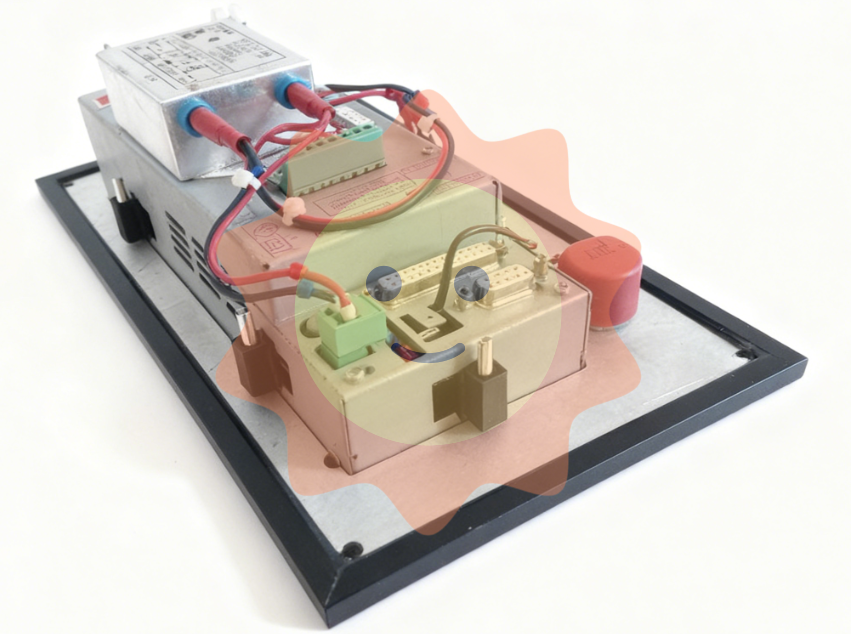

Rolls-Royce TDI-11 - Order No. 23090.1 Item Ref. 7352233---005

The Rolls-Royce TDI-11 stands out as a premier automation solution designed to meet the rigorous demands of the power industry, petrochemical sectors, and general automation applications. Engineered with precision and reliability at its core, the TDI-11 offers exceptional input/output (I/O) capacity and unparalleled durability, making it a cornerstone product within the Rolls-Royce automation portfolio. At its technical heart, the Rolls-Royce TDI-11 boasts a robust I/O interface that supports high-speed data acquisition and real-time processing, ensuring seamless integration with complex industrial systems. The unit is capable of handling a wide range of analog and digital signals, providing up to 128 discrete inputs and 96 outputs. This extensive capacity facilitates precise monitoring and control of process variables, allowing for optimized operational efficiency. The TDI-11 is equipped with advanced diagnostics and fault-tolerant features, supporting continuous operation in harsh environmental conditions such as extreme temperatures and corrosive atmospheres commonly found in petrochemical plants and power generation facilities. Its rugged enclosure meets stringent IP67 standards, ensuring protection against dust and water ingress, a critical factor for long-term reliability in industrial settings. Performance-wise, the Rolls-Royce TDI-11 is engineered to deliver rapid response times and high processing throughput, with a cycle time of under 1 millisecond for typical control loops.

This responsiveness is vital for applications requiring tight control tolerances, such as turbine management in power plants or safety system automation in chemical processing units. The device supports multiple communication protocols, including Modbus TCP/IP, Profibus, and CANopen, guaranteeing compatibility with existing infrastructure and facilitating integration with other Rolls-Royce automation products. In real-world scenarios, the TDI-11 excels in environments where precision and resilience are paramount. For instance, in the power industry, it manages complex control loops for gas turbines and generators, ensuring stable power output and efficient fuel consumption. Within petrochemical plants, the TDI-11 supervises critical safety interlocks and continuous process variables, maintaining operational safety while maximizing throughput. Additionally, its adaptability allows it to be deployed in general automation systems, from manufacturing assembly lines to remote monitoring stations, where dependable control and real-time data acquisition are essential. When compared to other models within the Rolls-Royce automation suite, the TDI-11 offers distinct advantages. Unlike the Rolls-Royce MEB-110, which focuses more on basic process control, the TDI-11 provides higher I/O density and faster processing speeds, enabling it to handle more complex control strategies.

Compared to the Rolls-Royce CCN 01 and CCN 01 REV. B models, which are primarily designed for communication networking, the TDI-11 integrates both control and communication functions, consolidating system architecture and reducing hardware footprint. Furthermore, while the Rolls-Royce UMAS UN-940 excels in remote monitoring, the TDI-11’s on-site processing capabilities offer superior real-time control, making it indispensable for mission-critical automation tasks. Alongside the Rolls-Royce TDI-11, we also offer complementary products such as the Rolls-Royce MPC-210 for advanced motion control, the Rolls-Royce H1127.0101 for high-precision sensor interfacing, and the Rolls-Royce PSR for safety-related process shutdowns. The Rolls-Royce 5880-PC1020 Rev. B and 5880-PC1019 REV-B provide reliable power supply and interface modules that enhance the TDI-11’s system integration. Additionally, the Rolls-Royce RRPWR2006 supports power management applications that pair well with the TDI-11’s control capabilities. For remote operations, the Rolls-Royce Sistema De Control Remoto offers seamless control extensions, while the Rolls-Royce AQM 4 LSP007 complements the TDI-11 with advanced air quality monitoring in industrial environments.

The application of the Rolls-Royce TDI-11 in the power industry, petrochemical, and general automation sectors underscores its versatility and robustness. Its combination of high I/O capacity, rapid processing, and resilient design makes it a preferred choice for engineers and system integrators seeking reliable automation solutions. As part of the broader range of Rolls-Royce automation products, the TDI-11 not only elevates system performance but also simplifies integration and enhances operational safety, ensuring long-term value and efficiency in demanding industrial applications.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-