Product Core Positioning and Basic Attributes ABB TTH300 is a high-precision header mounted temperature transmitter belonging to ABB's measurement and analysis product line. Its core function is to convert the signals collected by temperature sensors (such as thermistors, thermocouples) into standard electrical signals (4-20mA, etc.), and support multi protocol communication and redundancy design. It is suitable for temperature monitoring and control in industrial scenarios such as power, chemical, and metallurgical industries. The product originates from Switzerland and has industrial grade characteristics such as wide temperature adaptability, high protection, and strong anti-interference. It has also passed multiple international certifications such as CE, ATEX, IECEx, FM, CSA, etc., which can meet special environmental requirements such as ordinary and explosion-proof.

ABB TTH300 Head-mount temperature transmitter

Product Core Positioning and Basic Attributes ABB TTH300 is a high-precision header mounted temperature transmitter belonging to ABB's measurement and analysis product line. Its core function is to convert the signals collected by temperature sensors (such as thermistors, thermocouples) into standard electrical signals (4-20mA, etc.), and support multi protocol communication and redundancy design. It is suitable for temperature monitoring and control in industrial scenarios such as power, chemical, and metallurgical industries. The product originates from Switzerland and has industrial grade characteristics such as wide temperature adaptability, high protection, and strong anti-interference. It has also passed multiple international certifications such as CE, ATEX, IECEx, FM, CSA, etc., which can meet special environmental requirements such as ordinary and explosion-proof.

Key technical specifications and performance parameters

1. Signal input and measurement accuracy

Adapt to sensor types:

Thermistor (RTD): Supports Pt10/Pt50/Pt100/Pt200/Pt500/Pt1000 (compliant with IEC 60751, JIS C1604 and other standards), Ni series (DIN 43760), Cu series (OIML R 84), measurement range -200 ℃ to 850 ℃, minimum span 10 ℃, and input accuracy up to ± 0.08 ℃ (Pt100/Pt1000).

Thermocouple: Covering models such as K/J/N/T/E/R/S/B/C/D/L/U (compliant with IEC 60584, DIN 43710 standards), with a measurement range of -210 ℃ to 1820 ℃, a minimum span of 50 ℃ (some models 100 ℃), and an input accuracy of up to ± 0.35 ℃ (Type K).

Resistance/voltage measurement: Resistance 0-5000 Ω (accuracy ± 320m Ω), voltage -125 to 1100mV (accuracy ± 120 μ V).

Measurement characteristics: 24 bit AD converter ensures data acquisition accuracy, 16 bit DA converter ensures output stability, long-term drift ≤ ± 0.05 ℃/year (whichever is greater), and minimum environmental temperature impact ± 0.004 ℃/℃ (Pt100).

2. Output and Communication

Analog output: standard 4-20mA (configurable 20-4mA), dynamic range 3.8-20.5mA (compliant with NAMUR NE 43), fault current can be set (3.5mA low alarm/22mA high alarm, default 3.5mA low alarm after SW Rev. 03.00).

Communication protocol

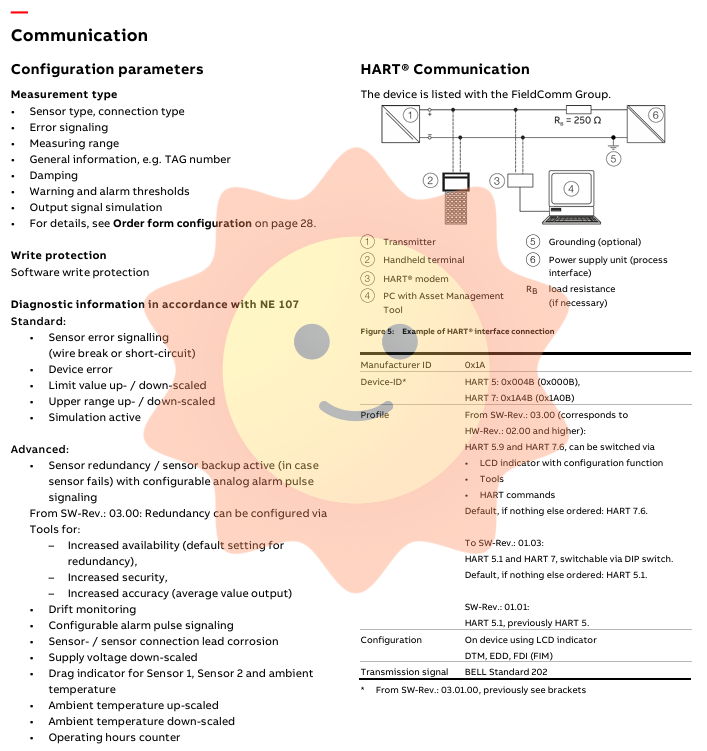

HART ®: Supports HART 5.1/5.9/7.0/7.6 (switchable), point-to-point/multi station mode, Burst mode, device ID 0x004B (HART5)/0x1A4B (HART7).

PROFIBUS PA ®: Compliant with IEC 61158-2, baud rate 31.25kBit/s, PA protocol 3.01, ID number 0x3470, supports FISCO standard.

FOUNDATION Fieldbus ®: H1 protocol (IEC 61158-2), baud rate 31.25kBit/s, ITK 5. x, device ID 000320001F..., integrated PID controller and LAS master station functions.

3. Environment and physical characteristics

Temperature adaptation: Standard ambient temperature range of -40 ℃ to 85 ℃, optional extension to -50 ℃ to 85 ℃; The storage/transportation temperature ranges from -50 ℃ to 85 ℃, and the explosion-proof design temperature range should refer to specific certificates (such as T6 level -50 ℃ to 56 ℃).

Protection and anti-interference: The body protection is IP20 (higher protection needs to be achieved with the shell), anti vibration (10-2000Hz, 5g), anti impact (30g), electromagnetic compatibility complies with IEC EN 61326-1 and NAMUR NE 21, electrostatic discharge (air 8kV/contact 6kV) has no effect, and radiation field interference is ≤ 0.5%.

Electrical isolation and power supply: Input output isolation of 3.5kV DC (approximately 2.5kV AC, 60s); The power supply adopts a two-wire system, with HART mode 11-30VDC (Ex scenario must comply with FISCO/ENTITY standards) and PROFIBUS/Fieldbus mode 9-32VDC (Ex scenario 9-17.5/24VDC), with an average current consumption of 12mA.

Core functions and features

1. Measurement and control enhancement function

Multi sensor configuration: Supports 1-2 sensors, enabling mean measurement, difference measurement, sensor redundancy backup, and drift monitoring (such as setting drift difference threshold and timeout), ensuring measurement continuity and accuracy.

Signal processing and diagnosis: Built in first-order digital filter (adjustable from 0-100s), supports sensor disconnection/short circuit detection (compliant with NAMUR NE 89), equipment fault alarm (such as hardware error, power supply undervoltage), and adds event tracking and configuration change records after SWRev.03.00. Diagnostic information complies with NAMUR NE 107.

Safety function: Only the HART version supports SIL function, and a single unit meets SIL 2 requirements. The redundant configuration can reach SIL 3 (compliant with IEC 61508), and the fault disconnect electronic component (FDE) ensures that the current does not exceed 20mA in the event of a fault.

2. Display and operation

LCD indicator: divided into Type A (supporting configuration function) and Type AS (display function only), both support 4-digit number+2-digit decimal display, with bar chart, can rotate 12 levels (30 ° each level), display content including sensor value, ambient temperature, output value/percentage and diagnostic information, working temperature -40 ℃ to 85 ℃ (display contrast and response time are limited when -50 ℃ to -20 ℃ or 70 ℃ to 85 ℃).

Installation, operation and maintenance

1. Installation specifications

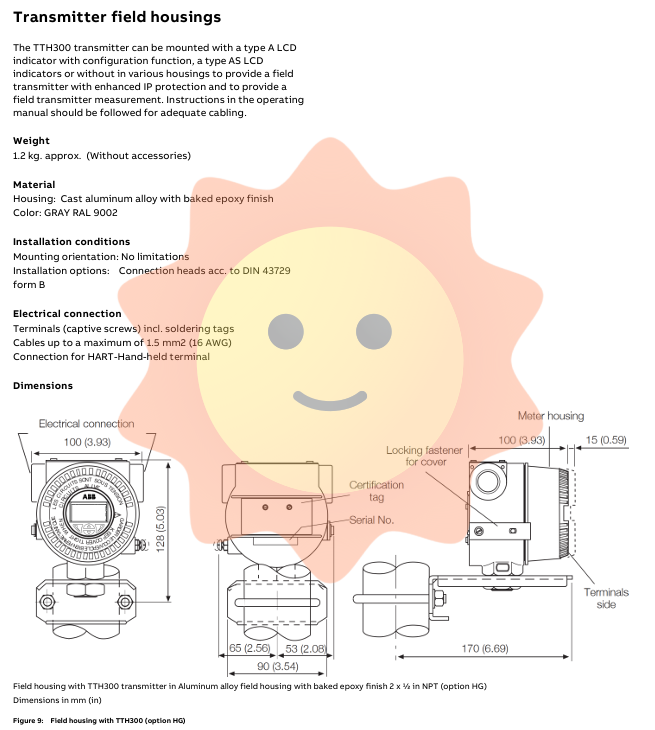

Installation method: No position limitation, supports DIN 43729 Form B junction box installation, 35mm rail installation (EN 60175, requires snap on base), on-site shell installation (aluminum/polyester/polycarbonate material, IP65 protection, including cable sealing sleeve).

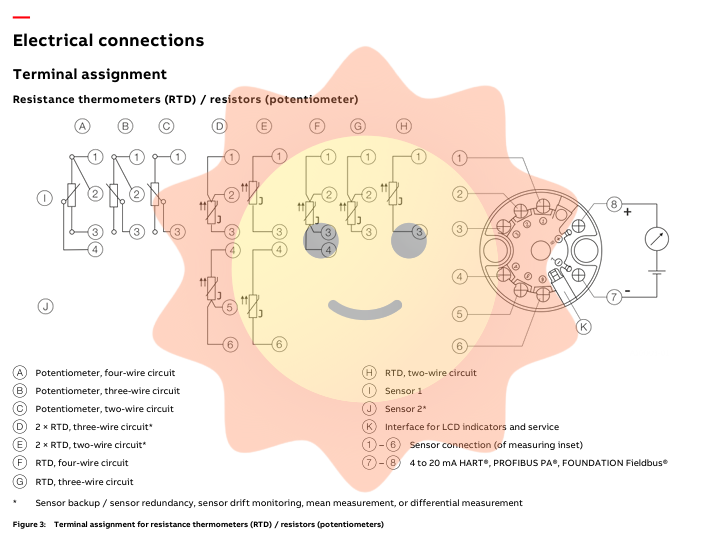

Wiring requirements: The terminals are made of captive stainless steel screws and support up to 1.5mm ² (AWG 16) wires. The sensor circuit needs to be shielded (single ended grounded). The thermal resistance supports 2/3/4 wire system (2-wire wire system with maximum resistance compensation of 100 Ω), and the thermocouple circuit has a maximum resistance of 3k Ω (1.5k Ω per wire).

2. Debugging and maintenance

Debugging tool: Parameter configuration can be performed through LCD indicator (Type A), HART handheld terminal, and PC tools (such as Asset Vision Basic, DAT200, supporting DTM/EDD/FDI technology), including measurement range, output mode, fault current, damping time, etc.

Maintenance strategy:

Daily: Check the status of indicator lights (power light constantly on, running light flashing, fault light off), monitor communication quality and measurement values through software.

Regular: Clean the shell dust (dry compressed air) and tighten the terminals every quarter; Annually calibrate measurement accuracy (standard signal source input) and backup configuration data; It is recommended to replace the built-in backup battery (if any) after running for more than 5 years.

Fault handling: Check the circuit or hardware based on the fault code (such as "E02: AI channel disconnection"). In explosion-proof scenarios, contact an authorized service provider for repair. Disassembly by oneself is prohibited.

Selection and ordering information

1. Basic model coding rules

The core code is TTH300 XX X X, and the key dimensions include:

Explosion proof levels: Y0 (non explosion proof), E1 (ATEX intrinsic safety, Zone 0/1/2), E2 (ATEX increased safety, Zone 2), H1 (IECEx intrinsic safety), L1/L2 (FM intrinsic safety/non essential), R1/R2 (CSA intrinsic safety/non essential), etc.

Communication protocols: H (HART), P (PROFIBUS PA), F (FOUNDATION Fieldbus).

Configuration types: BS (standard configuration), BF (customer customization without user curve), BG (customer customization with user curve included).

2. Optional accessories and services

Shell options: such as HG (aluminum alloy shell, 2 × 189 in NPT, epoxy resin coating), H1-H8 (shell of different materials/sizes, IP65 protection, including cable sealing sleeve).

Display and installation accessories: D3 (Type AS LCD), D4 (Type A LCD), SF (35mm rail clip kit), K3 (aluminum alloy shell mounting bracket).

Certificates and Services: CS (SIL2 Declaration of Conformity), C4/C6 (EN 10204 Declaration of Conformity/Inspection Certificate), EM/EP (5-point Factory Calibration Certificate), certificates can be delivered via email, courier, or with the equipment.

Certification and Compliance

Basic certification: CE certification (compliant with all applicable directives), SIL certification (IEC 61508, SIL 2/3).

Explosion proof certification:

ATEX/IECEx: Intrinsic safety type (Ex ia IIC T6-T1 Ga/Gb, applicable to Zone 0/1/2), increased safety type (Ex ec IIC T6-T1 Gc, applicable to Zone 2).

North American certification: FM/CSA/cFMus, intrinsic safety type (Class I Div 1/2, Groups A-D, Zone 0/1), non intrusive type (Class I Div 2, Zone 2).

Other compliance: Complies with DIN EN 60654-1 (climate class Cx), IEC 60068 (environmental testing), NAMUR series standards (NE 21/43/89/107), and some models support GOST (Kazakhstan), INMETRO (Brazil), NEPSI (China) certification.

Possible models needed

DC732F 3BDH000375R0001

TU715F 3BDH000378R0001

CM772F 3BDH000368R0001

PM783F 3BDH000364R0001

TB711F 3BDH000365R0001

GJR5252300R3101 07AC91F

GJR5252300R3101 07AC91H

LDSTA-01

SDCS-AMC-CLAS2

TVOC-2-240 1SFA664001R1001

CS31

RFO810

RMU811

5SHY6545L0001 AC10272001R0101 5SXE10-0181

5SHY4045L0001 3BHB018162R0001

SCYC51040 58052680E

CB801 3BSE042245R1

SCYC51010 58052515G

SCYC51090 58053899E

SCYC51020 58052582H

PP865A 3BSE042236R2

TP857 3BSE030192R1

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-