ABB UFC718AE101 HIEE300936R0101 is a high-performance industrial automation PCB circuit board belonging to the ABB UFC series (some data shows it belongs to the UFC700 sub series), which combines the dual attributes of a universal I/O module and a system interface board. Its core value lies in providing hardware support for signal transmission, data processing, logic control, and equipment communication for industrial control systems. It is a key component for PLC/DCS system integration and equipment expansion.

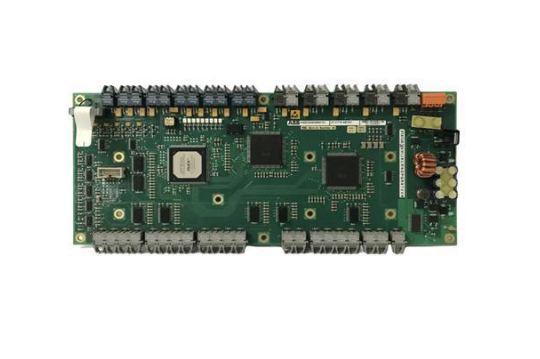

ABB UFC718AE101 HIEE300936R0101 PCB Circuit Board

Product core positioning

ABB UFC718AE101 HIEE300936R0101 is a high-performance industrial automation PCB circuit board belonging to the ABB UFC series (some data shows it belongs to the UFC700 sub series), which combines the dual attributes of a universal I/O module and a system interface board. Its core value lies in providing hardware support for signal transmission, data processing, logic control, and equipment communication for industrial control systems. It is a key component for PLC/DCS system integration and equipment expansion.

This product has two core application identities: one is to serve as a functional expansion board for ABB AC500 PLC system, achieving an increase in I/O points and communication interface expansion; The second is as a dedicated interface board for ACS1000 frequency converter, responsible for signal interaction and control command transmission between devices.

Key technical parameters

Basic Information

Model: UFC718AE101 HIEE300936R0101 Origin: Sweden Material: FR4

Dual model usually refers to different identification dimensions (functional model+production code) of the same product

Power parameters

Input voltage: 24V DC/48V DC Output voltage: 0~10V DC Rated current: 1A~2A maximum

There are slight differences in parameters among different suppliers, and the actual equipment manual shall prevail

Physical specifications

Size: 130mm × 70mm × 32mm (mainstream)/190mm × 65mm × 25mm Weight: 0.2kg~0.78kg

The size difference is due to the subdivision of application scenarios (PLC expansion board/inverter interface board)

Environmental adaptability

Working temperature: -40 ℃~85 ℃ Storage temperature: -40 ℃~85 ℃ Protection level: IP20/IP65

IP65 is suitable for strong dust/humid environments, and IP20 is the installation specification for indoor control cabinets

Communication capability

Protocol: Modbus RTU, Profibus, EtherCAT, CANopen Interface: RS-485, Ethernet

Support seamless integration of multiple protocols and adapt to mainstream industrial network architectures

Core functions and design features

1. Core functions

Signal processing and acquisition: Supports 16 digital I/O point expansion, with high-precision analog signal conversion and current measurement capabilities, can collect sensor data in real time and convert it into control signals.

Control logic execution: Equipped with a high-performance processor, it can handle complex logic such as sequential control and batch processing, and support precise control of motor speed and torque.

System Communication Hub: As an industrial network gateway, it enables data exchange between devices such as PLCs, frequency converters, and sensors, and is compatible with both wired and wireless control methods.

Fault protection mechanism: integrates overvoltage, overcurrent, and short-circuit protection functions to ensure the safe operation of equipment under harsh working conditions.

2. Design advantages

Modular structure: Adopting a plug and play design, it can be directly plugged into the CPU motherboard or terminal board, supporting local expansion of 10 I/O modules and distributed expansion of 7 modules.

High reliability design: Industrial grade component selection, strong electromagnetic interference resistance, suitable for wide temperature working environments ranging from -40 ℃ extreme cold to 85 ℃ high temperature.

Flexible compatibility: Suitable for multiple devices such as ABB AC500 PLC and ACS1000 frequency converter, and can add bus protocol modules such as Profibus and DeviceNet through communication expansion interfaces.

Application scenarios and industry adaptation

1. Core application scenarios

Equipment control expansion: Add digital I/O points to the PLC system to achieve terminal control such as motor start stop and valve operation.

Inverter interface adaptation: As a dedicated interface board for ACS1000 inverters, it connects the signal transmission between the inverter and the control system.

Data collection gateway: Real time monitoring of temperature, pressure and other sensor data, uploaded to the monitoring center through protocols such as Modbus.

Distributed Control Expansion: Remote I/O substation expansion is achieved through FBP bus adapters to meet the decentralized control requirements of large workshops.

2. Key application industries

Manufacturing industry: robot control of automotive production lines, precision counting and positioning of electronic component assembly.

Power industry: status monitoring and start stop control of generators and transformers, integration of substation automation systems.

Process industry: flow regulation, temperature control and other process parameter control in the petrochemical and metallurgical fields.

Building automation: centralized control and energy consumption data collection of air conditioning and ventilation systems.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-