ABB UFC760BE145 3BHE004573R0145 is a core interface board developed by ABB specifically for high-voltage industrial control systems. It belongs to the ABB high-voltage control module series and is widely applicable to scenarios such as medium and high voltage frequency converters, high-voltage motor control systems, and power equipment protection devices. As a "bridge" between high-voltage equipment and low-voltage control systems, this board undertakes key tasks such as high-voltage signal isolation and conversion, safe transmission of control instructions, and equipment status monitoring and feedback. It can achieve signal interaction between low-voltage control units and high-voltage actuators, while blocking the transmission of high-voltage danger signals to the low-voltage side through multiple isolation technologies, ensuring the safety of control systems and operators. It is an indispensable core component for safety assurance and signal conversion in high-voltage industrial control scenarios

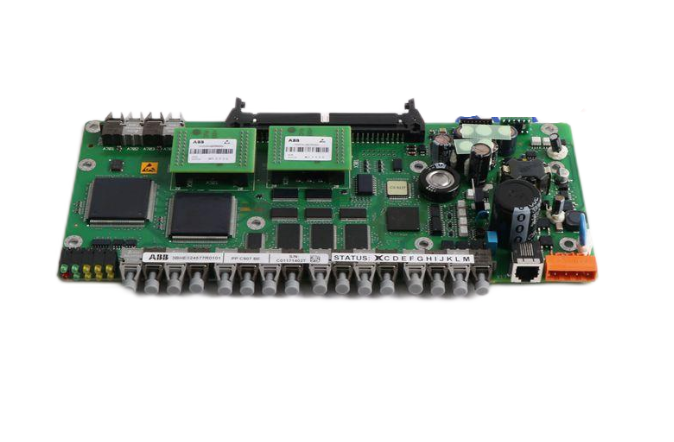

ABB UFC760BE145 3BHE004573R0145 High-Voltage Interface Board

Board Overview

ABB UFC760BE145 3BHE004573R0145 is a core interface board developed by ABB specifically for high-voltage industrial control systems. It belongs to the ABB high-voltage control module series and is widely applicable to scenarios such as medium and high voltage frequency converters, high-voltage motor control systems, and power equipment protection devices. As a "bridge" between high-voltage equipment and low-voltage control systems, this board undertakes key tasks such as high-voltage signal isolation and conversion, safe transmission of control instructions, and equipment status monitoring and feedback. It can achieve signal interaction between low-voltage control units and high-voltage actuators, while blocking the transmission of high-voltage danger signals to the low-voltage side through multiple isolation technologies, ensuring the safety of control systems and operators. It is an indispensable core component for safety assurance and signal conversion in high-voltage industrial control scenarios.

Its design strictly follows the IEC high-voltage equipment standard, integrating ABB's advanced signal isolation technology and high-voltage protection concept. It has extremely high insulation strength and anti-interference ability, and can work stably in industrial environments with high voltage and strong electromagnetic interference. It effectively solves the signal compatibility and safety isolation problems between high-voltage and low-voltage systems, providing solid support for precise control and safe operation of high-voltage equipment.

Core technical parameters

High voltage side adaptation voltage

AC 3kV-15kV (line voltage)

Adapt to commonly used medium and high voltage equipment in industry, covering the working voltage range of most high voltage motors and frequency converters

insulation strength

Between the high and low voltage sides: AC 20kV/1min, partial discharge ≤ 5pC

Having excellent insulation performance, it can effectively block high-voltage side danger signals and ensure the safety of low-voltage control systems

Signal transmission type

Input: High voltage side current/voltage signal; Output: Low voltage side standard signal (DC 4-20mA/0-5V)

Realize precise conversion of high-voltage analog signals to low-voltage standard signals, and adapt to various low-voltage controllers

Signal transmission accuracy

± 0.1% (full range)

High transmission accuracy ensures that the low-voltage control system obtains real operating status data of high-voltage equipment

Control signal interface

Low voltage side: DC 24V control command input, photoelectric isolation

Receive command signals from the low-voltage controller, drive the high-voltage side actuator through photoelectric isolation

working power supply

DC 24V ± 10%, power consumption ≤ 15W

Adapt to industrial standard low-voltage power supply systems, with low-power design to reduce energy consumption

Working temperature range

-20℃~65℃

Wide temperature design, capable of stable operation in extreme industrial environments such as high and low temperatures

anti-interference level

IEC 61000-4-2(ESD)±15kV;IEC 61000-4-4(EFT)±4kV

Strong anti-interference ability, ensuring the stability of signal transmission in high-voltage and strong electromagnetic environments

Structural Design and Core Features

3.1 Safety isolation and modular structure

The board adopts a modular design of "high voltage isolation area+low voltage signal area", with a physical isolation distance of ≥ 20mm between the high voltage side and the low voltage side. The interior is sealed with epoxy resin to further improve insulation performance and vibration resistance. The high-voltage side of the board is equipped with dedicated high-voltage wiring terminals (with anti misoperation design), and the low-voltage side uses standard DIN41612 connectors to achieve fast plug-in connection with the low-voltage controller, simplifying the installation and maintenance process. At the same time, the integrated status indicator module of the board displays real-time power supply status, signal transmission status, and fault information on the high-voltage side through LED lights, making it easy for on-site personnel to quickly judge the operation status of the board.

The overall size of the board meets the industrial rail installation standards and can be compatible with other ABB high-voltage control modules for installation. The shell is made of high-strength flame-retardant engineering plastic with a protection level of IP20, effectively resisting dust and slight water vapor erosion in industrial sites.

3.2 Core technological advantages

-Multiple safety isolation technology: integrating optoelectronic isolation, electromagnetic isolation, and physical isolation triple isolation design, with insulation resistance of ≥ 1000M Ω on the high-voltage side and low-voltage side, which can effectively block high-voltage breakdown and electromagnetic interference, ensuring the safety of low-voltage control systems and operators; At the same time, avoid interference signals from the low-voltage side that affect the operation of high-voltage equipment, and achieve bidirectional isolation protection.

-High precision signal conversion capability: Using imported high-precision signal conditioning chips and 18 bit AD conversion modules, combined with ABB's optimized signal compensation algorithm, precise conversion of high-voltage side current and voltage signals to low-voltage standard signals can be achieved. Even under conditions with large fluctuations in high-voltage signals, the stability and accuracy of output signals can be guaranteed, providing reliable data support for precise control of the control system.

-Complete fault protection function: The board has built-in overvoltage protection, overcurrent protection, overheating protection, and insulation monitoring functions. When the voltage on the high voltage side exceeds the preset threshold, the operating current of the board is abnormal, or the temperature is too high, immediately cut off the signal transmission channel on the high voltage side, and output a fault alarm signal to the low voltage controller; The insulation monitoring function can monitor the insulation status of the high and low voltage sides in real time, and warn in advance of the risk of insulation degradation.

-Strong environmental adaptability: using industrial grade wide temperature element devices, subjected to multiple rounds of environmental stress testing such as high-voltage pulses, high and low temperature cycles, vibration and shock; The board is equipped with efficient heat sinks and temperature compensation circuits inside, which can work stably in the temperature range of -20 ℃~65 ℃, suitable for high-temperature, high-voltage and harsh industrial scenarios such as metallurgy and power.

-High compatibility and interchangeability: The signal input type (current/voltage) and output signal range (4-20mA/0-5V) can be configured through hardware dip switches, compatible with mainstream control systems such as ABB AC800M series PLC and PCS6000 series frequency converter. It also supports seamless docking with third-party high-voltage equipment, reducing system integration costs.

Typical application scenarios

Based on its high insulation strength, high-precision signal transmission, and comprehensive protection functions, the UFC760BE145 3BHE004573R0145 high-voltage interface board is widely used in various high-voltage industrial control scenarios, becoming the core component for signal interaction between high-voltage and low-voltage systems, mainly including:

1. Medium to high voltage frequency converter system: As the interface core between the high voltage side of the frequency converter and the low voltage control unit, it real-time collects the current and voltage signals of the high voltage output side of the frequency converter, and transmits them to the low voltage controller after isolation conversion. At the same time, the PWM control instructions of the controller are isolated and transmitted to the high voltage IGBT drive module to ensure the precise speed regulation and safe operation of the frequency converter. It is compatible with ABB PCS6000, ACS8000 and other series of high voltage frequency converters.

2. High voltage motor control system: used for signal isolation and transmission of high-voltage motor starting cabinets and soft starters, collecting high-voltage signals such as motor stator current and rotor voltage, providing feedback on motor operation status, and safely transmitting control instructions such as start, stop, and speed regulation to the high-voltage actuator to avoid interference from high-voltage signals on the control unit. It is suitable for large-scale high-voltage motor control scenarios in the steel and chemical industries.

3. High voltage equipment in the power system: adapted to high-voltage switchgear and power transformer protection devices in substations, collecting signals such as high-voltage bus voltage and load current, and transmitting them to the power monitoring system after isolation and conversion. At the same time, the tripping and closing instructions of the protection device are safely transmitted to the high-voltage circuit breaker to ensure the stable operation of the power system and rapid response to faults.

4. Metallurgical high-pressure control equipment: used for the control system of high-pressure rolling mills and blast furnace fans in steel plants, collecting operating parameters on the high-pressure side of the equipment, isolating and transmitting control instructions from the low-pressure controller to the high-pressure drive unit, achieving precise control and safety protection of the equipment, avoiding control errors caused by high-pressure interference, and improving the stability of metallurgical production.

5. Chemical high-pressure reaction device: adapted to the pressure monitoring and control circuit of high-pressure reaction vessels in the chemical industry, collects pressure signals on the high-pressure side of the reaction vessel (converted into high-pressure current signals by pressure transmitters), isolates and transmits them to the low-pressure control system, and safely transmits the feeding and pressure relief control instructions of the control system to the high-pressure valve to ensure the safety and stability of the chemical reaction process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-