The ABB UFC921A (order number 3BHE024856P201) industrial control module is a multifunctional control unit launched by ABB for the high-end field of industrial automation, which integrates signal acquisition, logic control, and process regulation. It is a core component of high-end control systems such as ABB Symphony Plus. This module is designed specifically for the precise control requirements of complex industrial processes. Its core functions include real-time processing of multiple types of signals, execution of closed-loop adjustment algorithms, equipment linkage control, and status feedback. It is a key hub connecting the on-site execution layer and control layer.

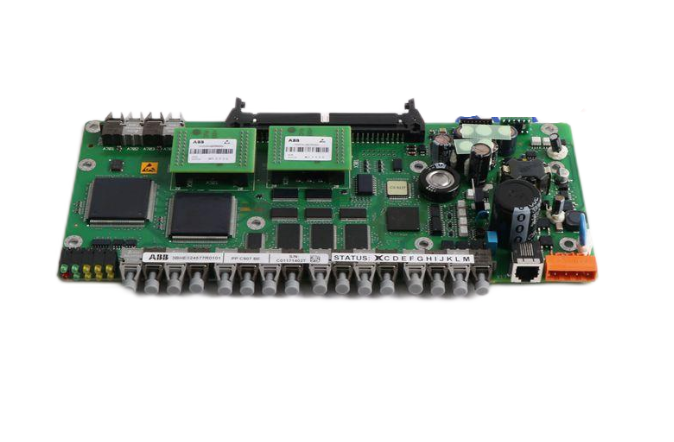

ABB UFC921A 3BHE024856P201 industrial control module

Product Overview

The ABB UFC921A (order number 3BHE024856P201) industrial control module is a multifunctional control unit launched by ABB for the high-end field of industrial automation, which integrates signal acquisition, logic control, and process regulation. It is a core component of high-end control systems such as ABB Symphony Plus. This module is designed specifically for the precise control requirements of complex industrial processes. Its core functions include real-time processing of multiple types of signals, execution of closed-loop adjustment algorithms, equipment linkage control, and status feedback. It is a key hub connecting the on-site execution layer and control layer.

Based on ABB's technological accumulation in the field of industrial control, this module has high real-time performance, high reliability, and strong environmental adaptability. It is widely used in industries such as thermal power generation, combined cycle power plants, large-scale chemical engineering, and petroleum refining that require strict control accuracy and system stability. It provides solid hardware support for the efficient operation of core production equipment, precise control of process parameters, and safety assurance of production processes.

Core Features

1. Multi functional integration, comprehensive control capability

The module adopts an integrated design of "acquisition operation control output", integrating multiple functions such as analog processing, digital logic control, pulse signal acquisition, and PID regulation. Supports 8 analog inputs, 4 analog outputs, 16 digital inputs/outputs, and 2 pulse counting channels. It can simultaneously process process process parameters such as temperature, pressure, and flow rate, as well as equipment switch status signals, without the need for additional dedicated modules to achieve comprehensive control of complex processes, greatly simplifying the system hardware architecture.

2. High real-time computing, fast response speed

Built in 32-bit high-performance embedded processor with a computing frequency of up to 500MHz, coupled with ABB's self-developed real-time operating system, can quickly execute complex PID adjustment algorithms, logic interlocking programs, and data processing tasks. The shortest analog signal acquisition cycle can reach 1ms, and the digital input response time is ≤ 0.1ms. It can accurately capture the instantaneous signal changes in the industrial field, ensure the real-time output of control instructions, and meet the control requirements of high-speed dynamic processes.

3. Multiple redundancy design ensures safe and reliable operation

In response to the high reliability requirements of key industrial scenarios, the module adopts a dual backup design of power redundancy, communication redundancy, and critical circuits. The power circuit supports dual 24V DC redundant power supply, and can seamlessly switch in case of any circuit failure; The communication interface supports redundant configuration to avoid control interruption caused by a single communication link failure; The core computing unit has a fault self recovery function, with an average time between failures (MTBF) of over 150000 hours, ensuring stable operation of the system in extreme situations.

4. Super strong anti-interference performance, suitable for complex environments

Adopting a comprehensive anti-interference design: the power inlet is equipped with a three-level EMC filtering circuit, which can effectively suppress harmonic and surge interference in the power grid; The signal channel adopts optoelectronic isolation and differential transmission technology, with an isolation voltage of 3000V AC, completely blocking the influence of external interference signals on the core circuit; The board adopts industrial grade wide temperature element devices, combined with a fully sealed shielding shell, which can work stably in harsh environments such as strong electromagnetic radiation, dust, and humidity. Its anti vibration performance meets the IEC 60068-2-6 standard.

5. Flexible compatibility and excellent adaptability for expansion

Strictly following ABB's open hardware interface specifications, it can directly adapt to Symphony Plus DCS systems, AC800M controllers, and third-party mainstream PLCs, supporting various industrial communication protocols such as PROFIBUS-DP, Modbus TCP, EtherNet/IP, and achieving seamless integration with upper level control systems. Standardized expansion slots are reserved for modules, which can be equipped with signal conditioning modules and communication expansion modules according to needs, flexibly expanding the scope of functions and adapting to personalized application scenarios in different industries.

6. Intelligent diagnosis and operation, convenient and efficient maintenance

Equipped with a comprehensive intelligent diagnostic system, it can monitor module power status, processor operation, signal channel integrity, and communication link quality in real-time. When a fault is detected, it will trigger a graded alarm through the onboard LED indicator light, and upload detailed information such as fault code and location to the control system through the communication bus, supporting remote fault diagnosis and parameter configuration. The module supports online hot plugging, which eliminates the need for downtime during maintenance and significantly reduces equipment inspection time.

Key technical parameters

Model/Order Number

UFC921A / 3BHE024856P201

Product Type

Multi functional industrial control module

Core processor

32-bit embedded CPU, clock speed ≥ 500MHz

Analog input (AI)

8 channels, supporting 4-20mA, 0-10V, thermocouple, and thermistor signals

Analog Output (AO)

4 channels, supporting 4-20mA, 0-10V, output accuracy ± 0.05% FS

Digital Input (DI)

16 channels, optional PNP/NPN, response time ≤ 0.1ms

Digital Output (DO)

16 channels, transistor output, rated current 2A/channel

pulse input

2 channels, supporting 0-100kHz pulse signal counting

control algorithm

Standard PID, cascade PID, feedforward control, ratio control

Isolation level

3000V AC between signal channel and power supply, 1500V AC between channels

working power supply

DC 24V ± 20%, supports dual redundant power supply, power consumption ≤ 15W

Working temperature range

-40℃ ~ +85℃

Storage temperature range

-55℃ ~ +125℃

communication interface

PROFIBUS-DP、Modbus TCP、EtherNet/IP、RS485

Protection level

IP20 (module level), compatible with IP54 and above protection level control cabinets

Dimensions (length x width x thickness)

220mm × 150mm × 30mm (approximately)

Installation method

35mm DIN rail installation/panel bolt fixation

Installation and usage precautions

-Model and compatibility confirmation: Before installation, the module model (UFC921A) and order number (3BHE024856P201) must be checked to confirm compatibility with the supporting control system (such as Symphony Plus); Check the appearance of the module for any damage, ensure that the interface pins are not bent or oxidized, and that the accessories (fasteners, wiring terminals) are complete and intact.

-Installation environment specifications: The module should be installed in a closed and ventilated industrial control cabinet, avoiding direct sunlight, dust accumulation, and corrosive gas erosion; The control cabinet should be kept away from strong interference equipment such as high-power frequency converters and welding machines. The distance between modules and other equipment should not be less than 10cm to ensure good heat dissipation; The working environment temperature should be controlled between -40 ℃ and+85 ℃, and the humidity should be ≤ 95% (no condensation).

-Wiring operation requirements: Before wiring, the module and system main power must be disconnected, and a torque wrench must be used to tighten the wiring terminals according to the wiring diagram (torque value 0.8-1.2N · m); The analog signal adopts shielded twisted pair cable, and the shielding layer is grounded at one end (grounding resistance ≤ 3 Ω); Separate the wiring of digital signal lines and power lines to avoid cross interference; Redundant power supplies need to be separately connected to independent power circuits to ensure power supply reliability.

-Parameter configuration and calibration: Module parameter configuration is completed through ABB dedicated configuration software (such as Symphony Plus Engineering Environment), including communication address, signal range, control algorithm parameters, redundancy mode, etc; Calibrate analog input/output channels using a standard signal source, record calibration data, and ensure that signal acquisition and output accuracy meet requirements; After the configuration is completed, conduct online testing to verify that the communication and control functions are normal.

-Operation monitoring and maintenance: Real time monitoring of module working status through the control system during daily operation, paying attention to the status of power indicator lights, communication indicator lights, and fault indicator lights; Regularly (every 3 months) inspect the module, clean the surface dust (blow dry compressed air after power failure), check the tightness of the wiring terminals and the insulation of the cables; When a module fails, it must be repaired by ABB authorized technicians, and non professionals are strictly prohibited from disassembling or modifying it without authorization.

-Hot plugging operation specification: The module supports online hot plugging, but it needs to be confirmed in the control system that the module is in an "offline" state before operation; When plugging or unplugging, hold the handles on both sides of the module and apply vertical force to avoid touching the interface pins; After replacing the module, it is necessary to re download and calibrate the parameters to ensure consistency with the original module parameters.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-