How can biomass energy development break the game?

The White Paper on 3060 zero-carbon Biomass Energy Development Potential, prepared by China Agricultural University, predicts that China's biomass emission reduction potential will reach 900 million tons by 2030 and 2 billion tons by 2060.

However, limited by the natural defects of biomass, how to turn it into a stable substitute for fossil energy is still difficult.

Inspired by modern coal chemical industry, in recent years, China has begun to develop technology to promote the gasification of woody biomass.

"Lignocellulosic biomass is the largest category in the total biomass resources. But it cannot produce biogas and biogas through conventional fermentation." Cheng Xu told this reporter that the EU has made some breakthroughs in the technology of methanation of bio-based synthetic natural gas with wood fiber raw materials in recent years, but there are still low efficiency problems, resulting in high equipment and production costs, and the competitiveness of the bio-natural gas market is not strong.

It is understood that there are cases of biomass thermochemical technology to achieve biomass gasification at home and abroad, but it is not possible to form an economically and technically feasible bio-based syngas platform and its transformation series of industries. The process pointed out that the application of biomass energy and downstream materials after gasification is very narrow, and the value-added rate is low, which determines the fundamental weakness of the biomass industry is difficult to change.

Can the biomass industry "turn over"?

The breakthrough of biomass gasification technology is the key

In the view of the process, whether it can break through the above technical barriers to biomass gasification is the hope of the biomass industry to completely "turn over".

In order to make a breakthrough, the coal-based modification of biomass, making its energy density and material flow transport close to coal, is a key prerequisite.

"Coal is produced hundreds of millions of years in the underground high pressure and high temperature environment, the key to biomass coalification is whether the biomass raw material can be simulated into coal in a few minutes." Procedures said, "At present, the biomass coalification technology, which is mainly studied by China Agricultural University and Inner Mongolia Xinmu Group, has been successful. This technology uses an innovative thermochemical method, at 260 degrees Celsius and 2.6 mpa, with superheated steam pressure depolymerization and other processes, to achieve hydrogen enhancement, deoxidation, surface functional groups are all removed, increasing the density and calorific value of biomass, making biomass feedstock into a jet powder fuel, with the same pneumatic conveying property as coal."

Xinmu Group has also developed a mobile equipment, its biggest feature is that it can be pulled to a place where biomass raw materials are very rich for biomass coal production, which can effectively solve the problem of biomass raw materials collection and transportation. Moreover, the equipment has a small limitation on the characteristics of raw materials, even if the water content of raw materials reaches 30%, 40%, it can be used, and straw and shrub are particularly suitable as raw materials.

It is worth noting that replacing pulverized coal with coal-based biomass can also achieve integration with modern coal chemical industry, and ultimately can make oil and gas. For example, coal-based biomass can be further converted into biobased hydrogen-rich gas, contributing to the development of the "hydrogen economy" and the realization of the "two-carbon" goal.

Based on the advantages of biomass coal technology, Zhang Yongmiao told reporters that this technology is likely to subend people's understanding of the application of biomass energy, and on the basis of fully investigating the relevant parameters of the technology, so as to predict its market prospects, it can be considered as an important new renewable energy utilization technology, included in the cooperation project between Huaxia Bank and the World Bank to support.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

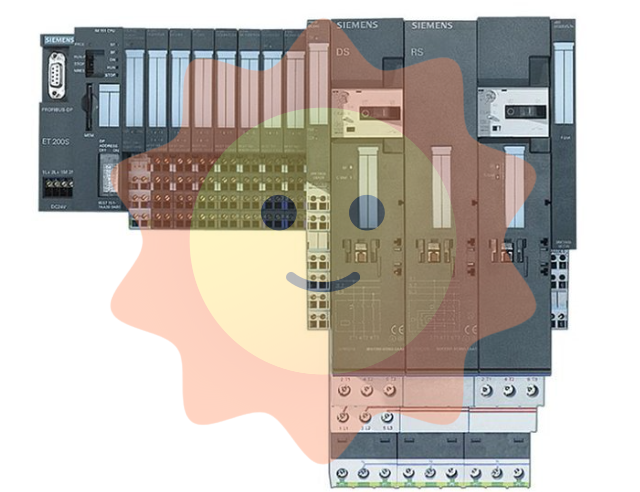

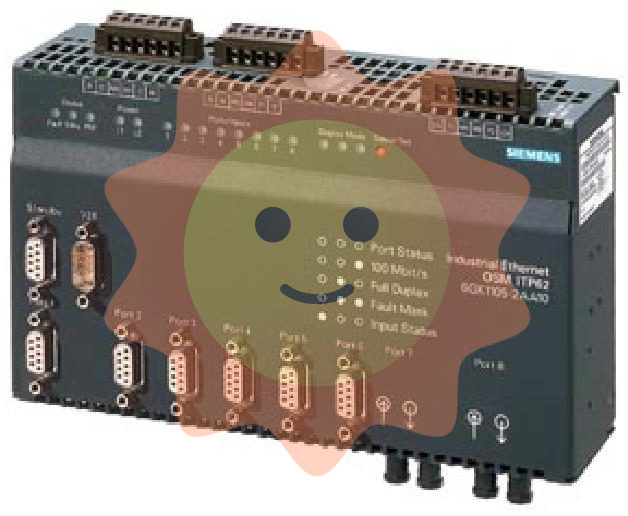

- Siemens

- Rockwell

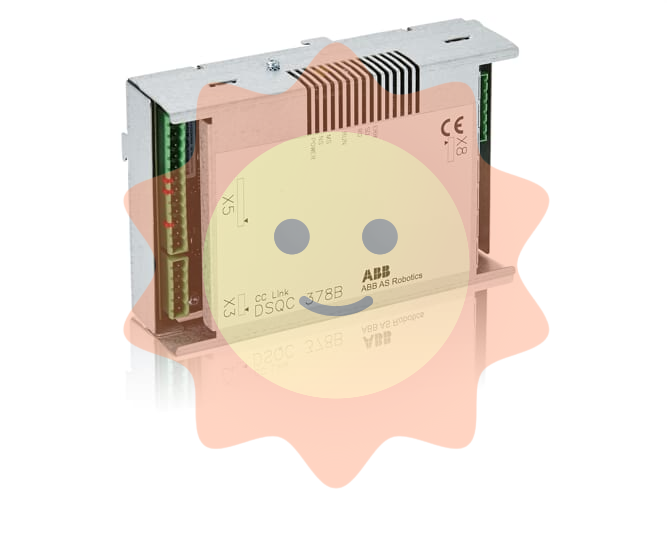

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

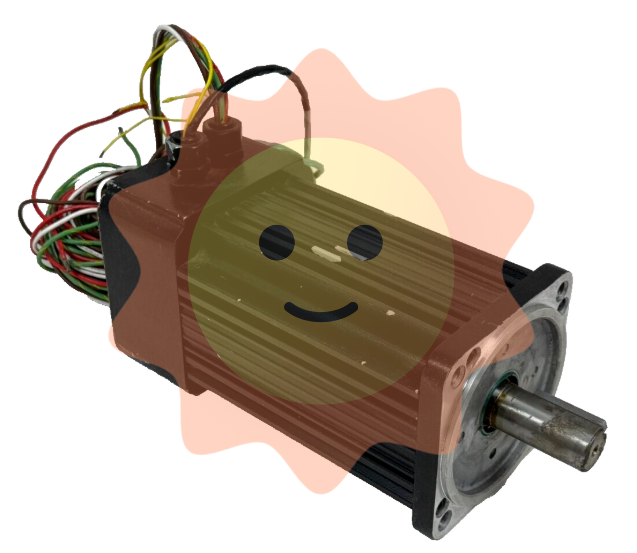

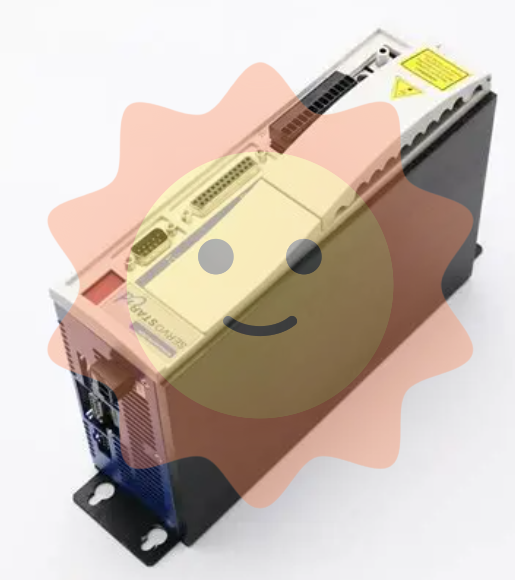

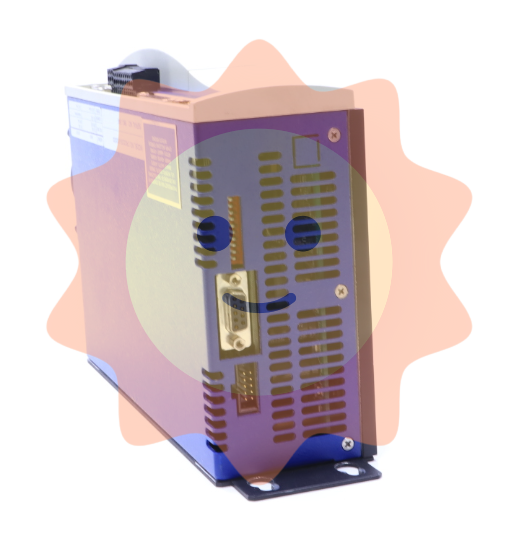

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

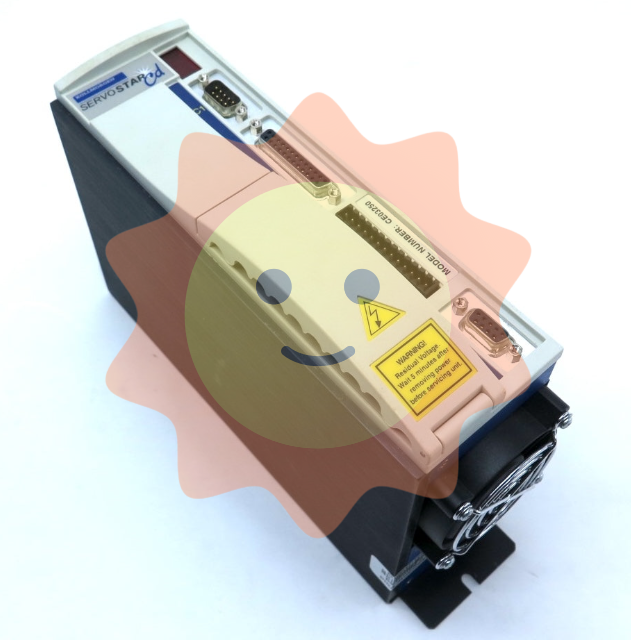

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

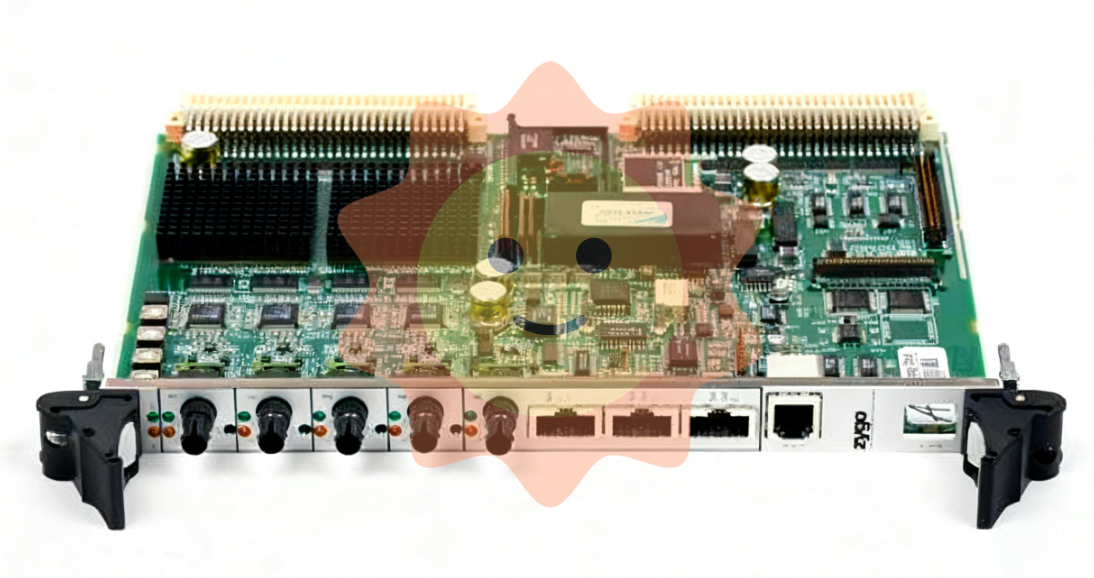

- ZYGO

- Aerotech

- DANFOSS

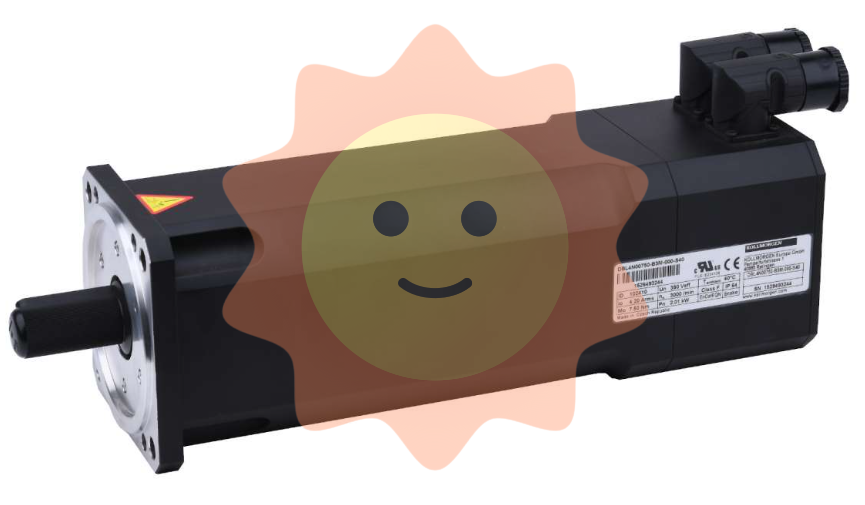

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com