Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Basic Unit

Estimated Shipping Size

Dimensions: 4.8" x 3.5" x 3.5"

(12.1 cm x 8.9 cm x 8.9 cm)

Weight: 1 lbs 13.9 oz (0.8kg )

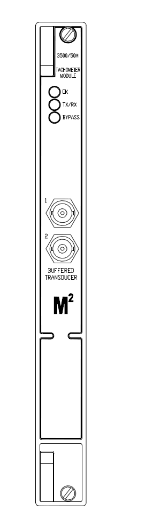

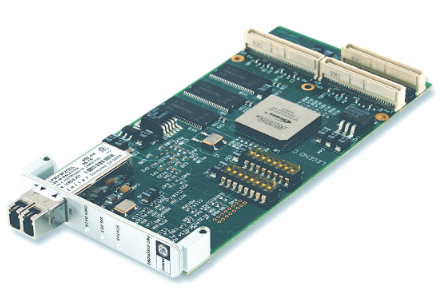

ABB 1SBP260011R2002 07KR51 Control Unit

Basic information

Model and Series: This control unit, model number 1SBP260011R2002, belongs to ABB's 07KR51 series, which is widely used in the field of industrial automation control and provides effective control solutions for a variety of industrial scenarios with its reliable performance and flexible configuration.

Product type: As a control unit, it is the core component of the automation control system, responsible for precise control and coordinated management of the whole system, receiving various input signals and generating corresponding output signals according to preset logic and algorithms, in order to realise the automation control of industrial equipment and production processes.

Performance characteristics

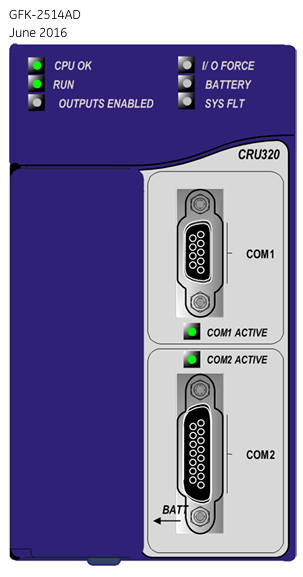

Input and output interfaces: usually equipped with multiple input and output interfaces to meet different signal transmission requirements. Input interface can receive signals from various types of sensors, such as temperature sensors, pressure sensors, limit switches, etc., these sensor signals can be digital or analogue signals, the input interface has good electrical compatibility and anti-interference ability to accurately collect external signals; output interface can be connected to relays, contactors, solenoid valves, motor drives and other actuating components, the output interface to provide The output interface can provide enough driving capacity to ensure that the actuators can work normally, so as to achieve the precise control of the production equipment.

Processor performance: Built-in high-performance processor with fast data processing capability and powerful logic computing ability, able to real-time processing of a large number of input signals, and quickly generate the corresponding output signals to meet the requirements of industrial production on the control speed and accuracy. The processor also supports multi-tasking and real-time operating system, able to run multiple control tasks at the same time, and ensure that each task can be timely response and processing.

Communication Function: It has a variety of communication interfaces, such as Ethernet interface, serial port, etc. It supports a variety of communication protocols, such as TCP/IP, Modbus, Profibus, etc. Through these communication interfaces and protocols, the processor is able to control multiple tasks simultaneously and ensure that each task can be processed in a timely response. Through these communication interfaces and protocols, the control unit can exchange data and communicate with other devices and systems to achieve remote monitoring, remote programming, distributed control and other functions, which is convenient for users to centralise the management and monitoring of industrial automation systems.

Programming and Configuration: ABB specific programming software and programming languages are supported, such as ABB Control Builder Plus, etc., which can be used by users for programming and configuration to realise a variety of complex control logics and functions. Programming software usually has a graphical interface and a rich function library, which is convenient for users to carry out programming and debugging, and improve programming efficiency and quality.

Reliability and stability: the use of high-quality electronic components and advanced manufacturing processes, with good anti-interference capability and environmental adaptability, can be in the harsh industrial environment for long-term stable operation. The control unit also has perfect fault diagnosis and alarm function, which can detect the faults in the system in time and send out the corresponding alarm signals so that the user can deal with them in time to ensure the continuity and safety of industrial production.

Application Fields

Industrial automation production line: widely used in automotive manufacturing, electronics manufacturing, food processing and other types of industrial automation production line, can be used as the control core of the production line, to achieve the coordinated control of the production line of robots, conveyor belts, processing equipment, etc., to ensure that the production line of efficient and stable operation.

Process control system: in the chemical industry, petroleum, electric power and other process industries, used to monitor and control various parameters in the production process, such as temperature, pressure, flow, liquid level, etc., through the cooperation with sensors and actuators, to achieve accurate control of the production process, to ensure product quality and production safety.

Intelligent Building System: It plays an important role in the HVAC system, lighting system and lift control system of intelligent buildings, which can achieve intelligent control of air conditioning and ventilation equipment, centralised management and energy-saving control of lighting equipment in the building, as well as control of lift operation and scheduling to improve the level of intelligence and energy efficiency of the building.

Other fields: It can also be applied in many industrial fields such as water treatment, pharmaceuticals, building materials, etc., as well as some special places with high requirements for automation control, such as airport baggage handling systems, logistics automation warehousing systems, etc., to provide reliable control solutions for a variety of complex industrial processes and equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com