The 216MB66 HESG324510M1 memory expansion module is developed based on ABB's rigorous industrial product standards, with core features concentrated in four advantages: "high compatibility, high reliability, high-speed read and write, and security and stability". In terms of compatibility, the module adopts ABB's dedicated bus interface design, which perfectly adapts to AC 800M, S800 and other series PLC controllers, without the need for additional adaptation circuits or protocol conversion, plug and play, simplifying the system integration process. In terms of reliability, it adopts industrial grade NAND flash memory chips and reinforced PCB layout, and has passed IEC 61000 series electromagnetic compatibility certification and environmental adaptability tests such as vibration and impact. The average time between failures (MTBF) exceeds 120000 hours, and it can operate stably in a wide temperature environment of -20 ℃~60 ℃ and industrial scenarios with high dust and strong electromagnetic interference. In terms of read and write performance, it supports high-speed parallel data transmission, with program read speeds of over 100MB/s and data write speeds of over 50MB/s. It can quickly respond to the storage access requirements of PLC controllers and avoid control logic lag caused by memory read and write delays. In terms of security, the built-in data verification and bad block management mechanism ensures the integrity and reliability of stored data, while supporting data backup and recovery functions to prevent data loss caused by unexpected power outages or module failures.

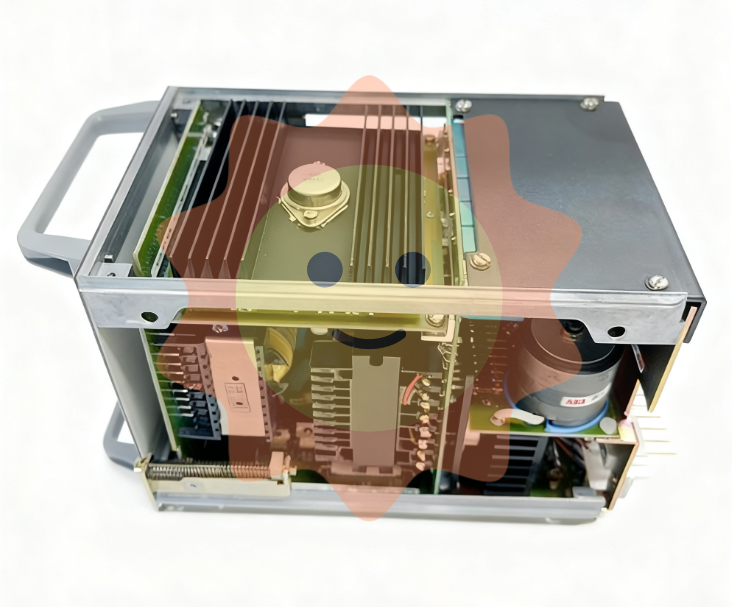

ABB 216MB66 HESG324510M1 PLC Memory Expansion Module

Basic characteristics of module

The 216MB66 HESG324510M1 memory expansion module is developed based on ABB's rigorous industrial product standards, with core features concentrated in four advantages: "high compatibility, high reliability, high-speed read and write, and security and stability". In terms of compatibility, the module adopts ABB's dedicated bus interface design, which perfectly adapts to AC 800M, S800 and other series PLC controllers, without the need for additional adaptation circuits or protocol conversion, plug and play, simplifying the system integration process. In terms of reliability, it adopts industrial grade NAND flash memory chips and reinforced PCB layout, and has passed IEC 61000 series electromagnetic compatibility certification and environmental adaptability tests such as vibration and impact. The average time between failures (MTBF) exceeds 120000 hours, and it can operate stably in a wide temperature environment of -20 ℃~60 ℃ and industrial scenarios with high dust and strong electromagnetic interference. In terms of read and write performance, it supports high-speed parallel data transmission, with program read speeds of over 100MB/s and data write speeds of over 50MB/s. It can quickly respond to the storage access requirements of PLC controllers and avoid control logic lag caused by memory read and write delays. In terms of security, the built-in data verification and bad block management mechanism ensures the integrity and reliability of stored data, while supporting data backup and recovery functions to prevent data loss caused by unexpected power outages or module failures.

Key technical parameters

storage capacity

Standard capacity 256MB, supports expansion to 512MB (industrial grade NAND flash)

interface type

ABB dedicated high-speed bus interface, compatible with AC 800M/S800 series PLC

Read and write speed

Read speed ≥ 100MB/s, write speed ≥ 50MB/s

Bus transmission rate

1Gbps (high-speed parallel transmission)

data protection

ECC error checking, power-off data protection (powered by supercapacitors), data encryption

Compatible with PLC series

ABB AC 800M, S800 series PLC controllers

power supply

Powered by PLC backplane bus, DC 5V ± 5%, power consumption ≤ 3W

working environment

Temperature: -20 ℃~60 ℃; Humidity: 5%~95% (no condensation); Protection level: IP20 (module body)

Installation method

35mm standard DIN rail installation, supports direct mounting of PLC backplane

Overall dimensions

80mm (length) x 60mm (width) x 40mm (height)

certification standard

IEC 61000-4-2 (ESD), IEC 61000-4-3 (RS), IEC 60068-2-6 (vibration), IEC 60068-2-27 (impact)

Applicable scenarios

The 216MB66 HESG324510M1 PLC memory expansion module is widely used in the field of industrial automation due to its advantages of large capacity storage, high-speed read and write, and high compatibility. Typical scenarios include:

1. Complex industrial control projects: In large-scale control projects in the chemical, metallurgical, and other industries, PLCs need to run complex control programs containing thousands of logical instructions, while storing a large amount of process parameters and equipment configuration information. The large storage capacity of modules can meet the storage needs of programs and data. For example, in the control of large-scale chemical reaction plants, PLC needs to control the coordinated action of dozens of valves and pump bodies. The control program has a large scale, and the modules can provide sufficient storage space to ensure the complete loading and stable operation of the program.

2. Massive data collection and storage: In production lines in industries such as intelligent manufacturing and food processing, PLCs need to collect real-time temperature, pressure, flow, and other data from hundreds of sensors and store them for a long time to achieve production process traceability. The high-speed read/write and large capacity storage capabilities of the modules ensure that data is not lost or delayed. For example, in the production line of automotive parts, PLC needs to record the processing parameters and testing data of each component, and the module can store continuous production data for one month, providing a basis for product quality traceability.

3. Implementation of advanced algorithms and control strategies: In fields such as new energy and precision manufacturing, PLCs need to run advanced algorithms such as PID adaptive control and fuzzy control. These algorithms have a large amount of program code and require storage of a large amount of intermediate calculation data. The module can provide sufficient memory space to support algorithm operation. For example, in the inverter control of photovoltaic power plants, PLC needs to implement maximum power point tracking (MPPT) through complex algorithms. The module can store algorithm programs and real-time power data to ensure efficient operation of the photovoltaic system.

4. Expansion of Distributed Control Systems: In distributed control systems (DCS) in fields such as power and municipal engineering, multiple PLC controllers work together through a network, and each PLC needs to store local control programs and shared data. Modules can achieve memory expansion for each PLC, improving the overall storage capacity of the system. For example, in urban water supply systems, PLCs distributed in different areas need to store their own pump control programs and water quality data. Modules can ensure that each PLC has sufficient storage space to achieve distributed control of the water supply system.

5. Upgrading old PLC systems: Some old PLC systems that have been running for many years have small built-in memory capacity and cannot meet new control requirements. By connecting modules, memory expansion can be achieved without replacing the entire PLC controller, reducing the cost of system upgrades. For example, in the control system of an old steel rolling mill in a steel plant, by adding modules to expand memory, the optimization and upgrading of control programs can be achieved, improving rolling accuracy and production efficiency.

Precautions for use

-Before installing the module, it is necessary to verify the model, storage capacity, and compatibility with the PLC series to match the on-site equipment. Check the appearance of the module for damage and whether the interface is oxidized or bent; The installation location should be selected in a dry and ventilated area inside the PLC control cabinet, away from high-temperature heat sources (such as frequency converters and heaters), strong electromagnetic interference sources (such as high-power motors), and corrosive gases. The module spacing should be kept at least 3cm to ensure good heat dissipation and avoid direct sunlight and rainwater splashing.

-During wiring and installation, it is necessary to disconnect the power supply of the PLC controller and strictly follow the instructions in the PLC manual to mount the module to the PLC backplane bus interface, ensuring a secure interface connection and avoiding communication failures caused by poor contact; If rail installation is used, it is necessary to ensure that the module is securely fixed to prevent interface loosening caused by vibration; It is strictly prohibited to plug and unplug modules while the PLC is live (except for models that support hot plugging) to avoid damaging the module and PLC interface.

-Before the module is put into operation, it needs to complete parameter configuration through ABB configuration software (such as Control Builder M), including storage partition division, data verification method, encryption parameters, etc. After configuration is completed, communication testing and read-write performance testing should be carried out to ensure that the module can be recognized by PLC normally and the data read-write speed meets the requirements; At the same time, it is necessary to backup the original control program and data of the PLC to prevent data loss during the configuration process.

-During operation, maintenance personnel need to regularly monitor the module's operating status through the PLC monitoring system, including storage capacity utilization rate, chip temperature, power supply voltage and other parameters. When the storage capacity utilization rate exceeds 90%, redundant data (such as expired historical records) should be cleared or storage capacity should be expanded in a timely manner; Check the module interface fastening once a month to prevent poor contact caused by vibration; Clean the surface of the module and the dust inside the control cabinet once a quarter to ensure smooth heat dissipation channels.

-When a module malfunctions, the fault code should be queried through the PLC configuration software first to distinguish whether it is a communication fault, storage chip fault, or power supply fault. If it is a communication fault, check the interface connection and bus configuration; If it is a storage chip failure, it is necessary to replace the module with the same model, and restore the program and data through backup data before replacement; The faulty module needs to be repaired by professional personnel, and it is strictly prohibited to disassemble it by oneself.

-The module needs to use ABB's official recommended configuration software and firmware version to avoid compatibility issues caused by the use of unofficial software; Firmware upgrade requires obtaining matching firmware files through official channels, backing up key data in the module before upgrading, and strictly prohibiting interruption of PLC power supply during the upgrade process. After the upgrade is completed, restart the PLC and verify that the module functions properly; In humid environments, it is necessary to strengthen dehumidification inside the control cabinet to prevent damage to the internal components of the module due to moisture.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-