ABB 2RCA013892A0003H power relay is a high-performance core control component developed by ABB Group for industrial power control systems, widely used in power transmission and distribution, industrial automation, rail transit, new energy and other fields. This relay, with ABB's profound technical accumulation in the field of power equipment, has high reliability, stable switching performance, and excellent environmental adaptability. It can accurately achieve circuit on-off control, signal conversion, and fault protection functions, providing key guarantees for the safe and stable operation of the power system.

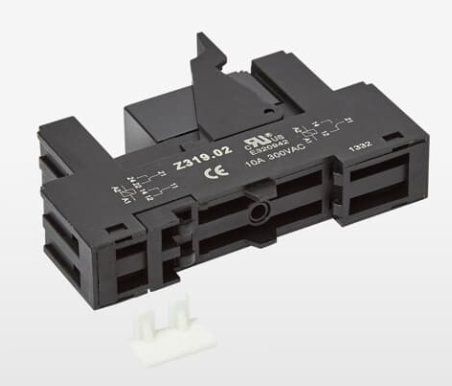

ABB 2RCA013892A0003H power relay

Product Overview

ABB 2RCA013892A0003H power relay is a high-performance core control component developed by ABB Group for industrial power control systems, widely used in power transmission and distribution, industrial automation, rail transit, new energy and other fields. This relay, with ABB's profound technical accumulation in the field of power equipment, has high reliability, stable switching performance, and excellent environmental adaptability. It can accurately achieve circuit on-off control, signal conversion, and fault protection functions, providing key guarantees for the safe and stable operation of the power system.

Core technical parameters

Model identification

2RCA013892A0003H

ABB standard model code, including product series, specifications, and version information

Coil voltage

According to the actual configuration, common options include AC 220V/DC 24V, etc

Supports multiple voltage levels and adapts to different power supply requirements under different working conditions

Contact form

Usually DPDT (Double Knife Double Throw) or customized specifications

Can simultaneously control the on/off of two circuits, meeting complex control logic requirements

Contact capacity

The rated current is generally 10A-30A (resistive load)

The specific capacity needs to be confirmed based on the load type (resistive/inductive/capacitive)

Action Time

≤ 10ms (typical value)

Quick response to ensure timely execution of control instructions

release time

≤ 8ms (typical value)

Quick reset to reduce the duration of circuit transition states

insulation resistance

≥100MΩ(500V DC)

Excellent insulation performance, effectively preventing leakage and insulation breakdown

Temperature resistance range

-40 ℃~+85 ℃ (working temperature)

Adapt to harsh industrial environments and work stably under high and low temperature conditions

mechanical life

≥ 10 million times

High strength mechanical structure design, extending product service life

electrical life

≥ 1 million times (under rated load)

Optimized contact materials reduce arc erosion and enhance electrical stability

Core performance characteristics

1. High reliability design

This relay adopts ABB's patented silver plated alloy technology for contacts, effectively enhancing the wear resistance and arc resistance of contacts, and reducing the risk of contact adhesion; The coil is wound with high-strength enameled wire, which has excellent heat resistance and insulation properties, and can maintain stable performance in long-term continuous operation. At the same time, the product has undergone rigorous reliability tests such as environmental aging and vibration impact, and complies with international standards such as IEC 61810, ensuring stable operation in complex industrial environments.

2. Accurate control performance

With optimized electromagnetic circuit design, the action and release thresholds of the relay are precise, with low dispersion, enabling precise control of the circuit; Fast action and release time (both less than 10ms), able to respond to control signals in a timely manner, especially suitable for power protection and automation control scenarios that require high response speed, such as rapid fault removal of transmission lines, precise control of equipment start stop, etc.

3. Excellent environmental adaptability

The product adopts a fully sealed shell structure, which has good dustproof, moisture-proof, and anti-corrosion performance, and the protection level can reach IP65 (specific to the product manual); The wide range of working temperatures (-40 ℃~+85 ℃) allows it to adapt to various harsh environments such as high temperature, high cold, and humid heat, and is widely used in special scenarios such as outdoor power equipment, metallurgical and chemical workshops, and rail transit carriages.

4. Convenient installation and maintenance

The relay adopts standard guide rail installation or bolt fixing method, which is easy to install and disassemble and suitable for mainstream industrial control cabinet layout; The contact status is clear and visible, and some models are equipped with action indicator lights, making it easy for on-site personnel to quickly determine the working status of the equipment; Modular design of product structure, key components can be separately inspected and replaced, reducing maintenance costs and downtime.

Applicable application scenarios

-Transmission and distribution system: used for circuit switching, signal amplification, and fault protection in high-voltage switchgear and low-voltage distribution cabinets, such as overcurrent protection, undervoltage protection, etc., to ensure the safe operation of the power grid.

-Industrial automation: As the executing component of PLC output interface, it controls the start and stop of industrial equipment such as motors, valves, heaters, etc., and is widely used in production lines of industries such as automobile manufacturing, mechanical processing, food and beverage.

-Rail transit: Suitable for the traction power supply system and onboard equipment of subways and high-speed railways, achieving circuit isolation control, energy conversion, and fault diagnosis, meeting the requirements of high safety and anti-interference of equipment for rail transit.

-In the field of new energy, it is used for on/off control, voltage monitoring, and protection of DC circuits in photovoltaic inverters, wind power converters, and energy storage systems to ensure the stable grid connection and safe operation of new energy generation systems.

Installation and usage precautions

Before installation, it is necessary to confirm that the coil voltage, contact capacity, and other parameters of the relay match the actual working conditions to avoid equipment damage or control failure caused by parameter mismatch.

2. During the installation process, ensure that the wiring is secure and avoid false connections that may cause contact heating or arc erosion; At the same time, pay attention to distinguishing between coil terminals and contact terminals to prevent incorrect wiring.

3. Relays should be installed in an environment with good ventilation, no severe vibration, no corrosive gases, and strong magnetic fields, away from high temperature heat sources, to ensure that their operating temperature is within the rated range.

4. During use, regular inspections should be conducted on the relay to check for any erosion or oxidation of the contacts, as well as any abnormal conditions such as overheating or odor in the coil. Any problems found should be promptly addressed.

When replacing relays, products of the same model or compatible parameters should be selected to avoid arbitrary replacement that may cause system control logic disorder or equipment failure.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-