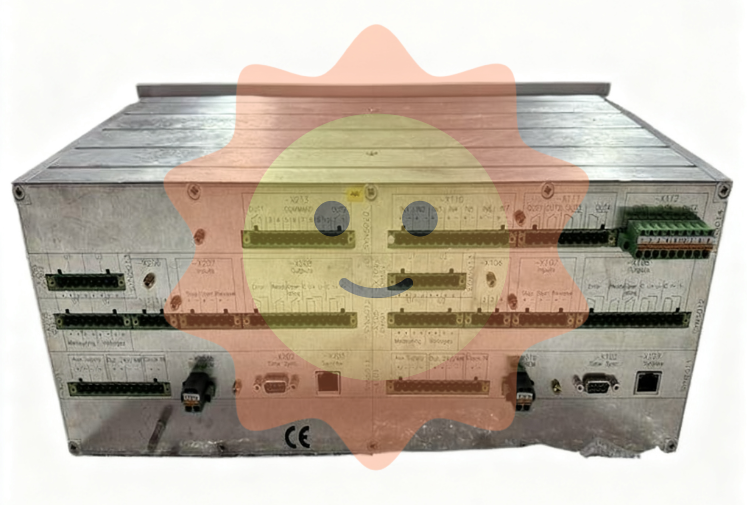

This product is an industrial grade synchronizer under the ABB brand, which is a key core component in power and industrial automation control systems. Its core identification information is as follows:

-Brand: ABB (a leading global enterprise in industrial automation and power technology)

-Model and specification: 3BHB006716R0277

-Product series: SYN5302A-Z.V277

-Product type: Synchronizer

-Applicable fields: Mainly used in scenarios that require precise speed and phase synchronization, such as thermal power generation, hydropower generation, industrial motor control, and grid connection, especially playing a core role in the start-up and grid connection process of large power generation units.

ABB 3BHB006716R0277 SYN5302A-Z.V277 synchronizer

Basic Product Information

This product is an industrial grade synchronizer under the ABB brand, which is a key core component in power and industrial automation control systems. Its core identification information is as follows:

-Brand: ABB (a leading global enterprise in industrial automation and power technology)

-Model and specification: 3BHB006716R0277

-Product series: SYN5302A-Z.V277

-Product type: Synchronizer

-Applicable fields: Mainly used in scenarios that require precise speed and phase synchronization, such as thermal power generation, hydropower generation, industrial motor control, and grid connection, especially playing a core role in the start-up and grid connection process of large power generation units.

Core functions and roles

As a synchronous control unit in industrial control systems, the core function of ABB 3BHB006716R0277 SYN5302A-Z.V277 synchronizer revolves around "precise synchronization", including the following aspects:

1. Speed and phase detection: Real time collection of speed signals and voltage phase signals of the generator set or controlled motor. Through an internal high-precision calculation module, the matching degree between the equipment operating status and the grid parameters is accurately identified, with a detection accuracy of milliseconds, providing reliable data support for synchronous control.

2. Synchronous adjustment control: Based on the detected speed difference and phase difference data, automatically output adjustment signals to the speed control system or excitation system, dynamically adjust the speed and voltage phase of the generator set, gradually align the equipment parameters with the grid or target system parameters, and achieve stable synchronization.

3. Grid connection signal output: When the speed, phase, voltage and other parameters of the controlled equipment meet the grid connection conditions, the synchronizer will accurately output the grid connection permission signal, control the action of the circuit breaker and other actuators, ensure the safe and impact free integration of the generator set into the grid, and avoid equipment damage or grid fluctuations caused by synchronization deviation.

4. Fault monitoring and protection: Equipped with comprehensive self diagnosis and external fault monitoring functions, it can monitor its own circuit status and input signal stability in real time. When there are faults such as abnormal speed, sudden phase change, signal interruption, etc., an alarm signal will be promptly issued and the relevant control circuit will be cut off to prevent the fault from expanding and ensure the safe operation of the system.

Product features and advantages

-High precision control: Using ABB's patented signal processing algorithm and high-precision components, the synchronization control error is extremely small, which can meet the strict requirements of synchronization accuracy in high specification industrial scenarios and effectively improve the stability of system operation.

-High reliability: Following industrial grade product design standards, it has good resistance to electromagnetic interference, a wide temperature operating range (usually suitable for working environments of -20 ℃~60 ℃), and anti vibration performance. It can work stably in complex industrial sites for a long time, with a long mean time between failures (MTBF).

-Strong compatibility: Supports seamless integration with various ABB DCS systems (such as AC800M, Symphony Plus, etc.) and third-party industrial control systems, with rich input and output signal interfaces that can adapt to different types of peripheral devices such as speed sensors and voltage transformers, and strong versatility.

-Easy to operate: It has clear status indication functions (such as power lights, synchronization status lights, fault alarm lights, etc.), and some models support parameter configuration and status monitoring through the upper computer, which is convenient for on-site operation and debugging personnel.

Installation and usage precautions

1. Installation environment requirements: It should be installed in a well ventilated, non violent vibration, non corrosive gas and dust control cabinet, avoiding direct sunlight and rainwater immersion. The ambient temperature and humidity should comply with the product manual specifications.

2. Wiring specifications: Strictly follow the product wiring diagram to ensure accurate connection of the positive and negative poles of the power supply and signal input and output lines. The wiring terminals should be securely fastened to prevent signal abnormalities or equipment damage caused by poor contact; Power lines and signal lines should be wired separately to reduce electromagnetic interference.

3. Parameter configuration: According to the actual application scenario (such as the rated speed of the generator set, grid frequency, synchronization allowable deviation, etc.), the internal parameters of the synchronizer are correctly configured through special tools or upper computers. After the parameter settings are completed, they need to be verified to ensure compliance with on-site operation requirements.

4. Daily maintenance: Regularly check the working status of the synchronizer, clean the dust on the surface of the equipment and inside the control cabinet; Regularly verify the accuracy of input and output signals, and check for loose wiring terminals; If a fault alarm is detected, the machine should be stopped for inspection in a timely manner to avoid running with faults.

5. Professional operation: Installation, debugging, maintenance and other operations must be completed by qualified professional technicians. Non professionals are strictly prohibited from operating or dismantling equipment without authorization.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-