ABB 3HAC5518-1 is a multifunctional industrial control module designed for small and medium-sized industrial automation control scenarios. Its core is the ABB robot assisted control system (such as IRB series robot peripheral device control) and distributed control system, mainly responsible for on-site signal acquisition, logic operation, equipment linkage control, and data exchange tasks. As a key bridge connecting upper level controllers and lower level sensors/actuators, it can achieve integrated processing of analog and digital signals, support multiple industrial communication protocols, adapt to small and medium-sized production lines, equipment single machine control and other scenarios, and provide cost-effective control solutions for industrial automation.

ABB 3HAC5518-1 Industrial Control Module

Product Overview

ABB 3HAC5518-1 is a multifunctional industrial control module designed for small and medium-sized industrial automation control scenarios. Its core is the ABB robot assisted control system (such as IRB series robot peripheral device control) and distributed control system, mainly responsible for on-site signal acquisition, logic operation, equipment linkage control, and data exchange tasks. As a key bridge connecting upper level controllers and lower level sensors/actuators, it can achieve integrated processing of analog and digital signals, support multiple industrial communication protocols, adapt to small and medium-sized production lines, equipment single machine control and other scenarios, and provide cost-effective control solutions for industrial automation.

This module adopts a compact hardware design, with low power consumption and high reliability characteristics, and can be flexibly compatible with ABB series I/O expansion modules, servo drives, and third-party industrial equipment. It is widely used in fields such as electronic processing, food packaging, and small machinery automation, and is a core component to ensure stable operation and improve control accuracy of small and medium-sized industrial equipment.

Specifications

Basic Information

Model: 3HAC5518-1 Series: ABB Industrial Automation Auxiliary Control Series Type: Small and Medium sized Industrial Control Module (including Analog and Digital Processing)

Adapt to ABB robot peripheral control and small and medium-sized distributed control systems

Computational performance

Main processor: 32-bit industrial grade CPU, main frequency 500MHz, logical operation speed: 500 instructions/μ s, program storage capacity: 2GB flash memory (expandable to 8GB), data cache capacity: 512MB DDR3 RAM

Meet the real-time computing needs of small and medium-sized control scenarios, and support the operation of basic control algorithms

Control ability

Maximum number of control axes: 4 axes (servo motor/stepper motor) Control accuracy: ± 0.005mm (position control), ± 0.05rad/s (speed control) Motion mode: point-to-point control, simple linear interpolation PID control: supports position PID, parameter manual tuning

Multi axis collaborative control suitable for single machine equipment and small production lines, such as conveyor belts and small robotic arms

Signal interface

Analog input (AI): 6 channels, supporting 4-20mA/0-5V, resolution 12 bit analog output (AO): 3 channels, supporting 4-20mA/0-5V, accuracy ± 0.5% digital input (DI): 12 channels, supporting 24VDC wet/dry contact digital output (DO): 8 channels, transistor output( 1A@24VDC )/Relay output( 2A@250VAC , optional) Encoder interface: 2 channels, supporting incremental encoders (A/B phase, maximum frequency of 500kHz)

Multi type signal interfaces cover the signal interaction needs of most small and medium-sized devices, without the need for additional expansion

Communication and Networking

Communication Protocol: Modbus RTU, Profinet RT (Basic Edition), RS485 Custom Protocol Interface Type: 1 100Mbps Ethernet port (RJ45), 1 RS485 serial port, 1 CAN interface (optional) Communication Delay: ≤ 10ms under Profinet RT protocol

Meet the device interconnection needs of small and medium-sized systems, support simple communication with upper computers and third-party devices

Power supply and power consumption

Working power supply: 24VDC (± 15%) Typical power consumption: 8W (full load operation) Maximum power consumption: 12W Power protection: overvoltage protection (triggered by 32VDC), overcurrent protection (triggered by 1A), reverse connection protection

Low power design suitable for small control cabinet power supply, multiple protections to prevent module damage caused by abnormal power supply

Environmental adaptability

Working temperature: -10 ℃ to 60 ℃ Storage temperature: -30 ℃ to 80 ℃ Relative humidity: 5% -90% (no condensation, at a temperature of 40 ℃) Vibration level: IEC 60068-2-6, 10-500Hz, 3g Acceleration impact level: IEC 60068-2-27, 20g Acceleration (11ms duration) Protection level: IP20 (module body), IP54 (front connector, with dust cover)

Suitable for the conventional environment of small and medium-sized industrial sites, able to tolerate mild vibration and temperature and humidity fluctuations

Physical specifications

Size: 95mm x 130mm x 45mm (length x width x height) Weight: 0.5kg Installation method: DIN rail installation (compatible with 35mm standard rail) Shell material: flame retardant ABS plastic (UL94 V-0 grade)

Ultra compact design, occupying only one standard DIN rail slot, saving control cabinet space

Security and Certification

Safety certification: IEC 61010-1 (Safety of Measurement and Control Equipment), EN ISO 13849-1 PL b Electromagnetic Compatibility (EMC): Compliant with IEC 61000-6-2 (Immunity), IEC 61000-6-4 (Emission Limits) Environmental certification: RoHS 2.0 (Lead free, Halogen free)

Meets safety standards for small and medium-sized industrial equipment, suitable for non high risk control scenarios

Performance characteristics

High cost-effectiveness and compact design: With an ultra small volume (95mm × 130mm × 45mm) occupying only one DIN rail slot, it is suitable for small control cabinets with limited space; Integrating 6 AI channels, 3 AO channels, 12 DI channels, and 8 DO channels, a single module can meet the signal processing needs of small and medium-sized devices without the need for additional expansion, significantly reducing hardware costs.

Full coverage of basic control functions: supports 4-axis point-to-point control and simple linear interpolation, suitable for the motion control needs of small robotic arms, conveyor belts, and other equipment; The built-in position based PID algorithm can achieve closed-loop control of process parameters such as temperature, pressure, and flow rate, with a steady-state error of less than 0.5%, meeting the accuracy requirements of small and medium-sized production scenarios.

Flexible signal and communication adaptation: The analog interface is compatible with 4-20mA/0-5V signals and can be directly connected to common industrial sensors such as pressure transmitters and temperature sensors; Digital output supports both transistor and relay types, suitable for actuators of different powers (such as solenoid valves and small motors); At the communication level, it supports Modbus RTU and Profinet RT, and can be easily interconnected with ABB robot controllers and third-party PLCs (such as Mitsubishi and Omron).

High reliability and low maintenance: The core components are selected from industrial grade, with an average time between failures (MTBF) of over 80000 hours; The power supply has triple protection against overvoltage, overcurrent, and reverse connection to prevent module damage caused by abnormal power supply; The front-end connector is equipped with a dust cover to reduce dust intrusion and lower maintenance frequency.

Convenient debugging and operation: Supports ABB Control Builder simplified version software debugging, with a simple and easy to understand interface, and can complete parameter configuration and program writing without professional programming experience; The front-end LED indicator lights (power, communication, I/O status) intuitively display the working status of the module, which can quickly locate the problem and reduce the difficulty of operation and maintenance when there is a fault.

Working principle

The workflow of ABB 3HAC5518-1 industrial control module revolves around signal acquisition instruction parsing operation processing control output state feedback, adapting to the simplified requirements of small and medium-sized control scenarios, as follows:

Signal acquisition and instruction reception: The module collects process signals from on-site sensors (such as 4-20mA pressure signals and 0-5V temperature signals) through analog input interfaces, and collects equipment status signals (such as limit switch and emergency stop button signals) through digital input interfaces; At the same time, control instructions (such as motion parameters and PID settings) issued by the upper computer (such as touch screen, small PLC) are received through a 100Mbps Ethernet port or RS485 serial port, and all data is temporarily stored in the internal data cache area.

Data parsing and computation: The main processor (500MHz CPU) parses and processes the collected signals and instructions. For motion control instructions, it generates target position and speed parameters for the 4-axis motor; For PID control requirements, compare the actual values of process parameters with the set values, calculate the deviation, and generate control quantities through PID algorithm; For logic control requirements (such as "starting the conveyor belt when the sensor detects the material"), execute the preset logic program to determine whether to trigger the actuator action.

Control signal output: The processed control signal is converted by the internal driving circuit and output. The motion control signal is transmitted to the servo driver through the encoder interface, driving the motor to move along the target trajectory; Analog output signals (such as 4-20mA) drive actuators (such as regulating valves) to operate and adjust process parameters; The digital output signal triggers the start stop of equipment such as solenoid valves and small motors, achieving equipment linkage.

Status feedback and fault monitoring: The module collects real-time action feedback signals of the actuator (such as motor operation status, valve switch feedback) and its own working status (such as power supply voltage, CPU temperature), and sends them back to the upper computer through the communication interface for monitoring by the operator; If an abnormality is detected (such as analog signal exceeding the range, communication interruption, motor overcurrent), an alarm will be triggered immediately: the LED fault light will remain on, and the output signal will be cut off (or maintained in the current state) to prevent the fault from expanding.

Precautions

Installation specifications:

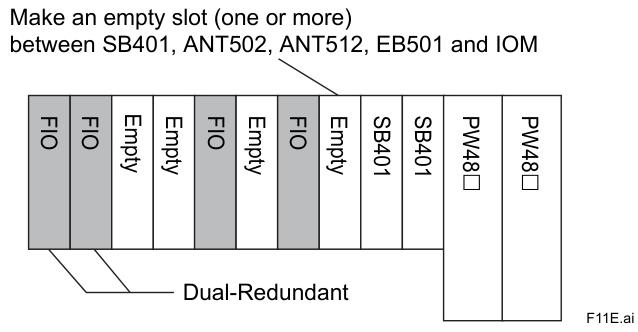

It needs to be installed in a small control cabinet to avoid direct sunlight and liquid splashing; When installing DIN rails, a space of ≥ 10mm should be reserved on both sides of the module to ensure good heat dissipation and prevent a decrease in signal acquisition accuracy caused by high temperatures; When the front-end connector is not in use, it is necessary to cover it with a dust cover to reduce dust intrusion.

Before installation, confirm that the module power specifications (24VDC ± 15%) match the power supply, and that the power circuit is equipped with a 1.5A fuse to prevent short circuits; The analog signal cable adopts shielded twisted pair, and the shielding layer is grounded at one end (grounding resistance ≤ 4 Ω) to avoid electromagnetic interference; The distance between digital cables and power cables (such as 220V motor cables) should be ≥ 100mm to prevent cross interference.

Wiring requirements:

The wiring of analog input channels needs to distinguish between signal types. For 4-20mA signals, ensure that the positive and negative poles are connected correctly. Reverse connection may cause channel damage; The thermistor signal needs to be converted to 4-20mA/0-5V through an external signal conditioning module before being connected, and the module does not directly support thermistor signals.

Digital output channel: transistor output( 1A@24VDC )Only suitable for small actuators (such as solenoid valves), high-power equipment (such as 220V small motors) requires the use of relay output versions and the configuration of intermediate relays to avoid overloading and burning out the output circuit.

Debugging and configuration:

During the first debugging, the communication parameters (such as IP address, baud rate) and I/O signal type configuration are completed through the simplified version of Control Builder software. After saving the parameters, the module needs to be restarted to take effect; When debugging PID parameters, first set a small proportional coefficient and gradually increase it until there is no significant overshoot, then adjust the integration time to ensure that the steady-state error meets the requirements.

When debugging motion control, first test the direction and speed of the motor motion on a single axis, confirm that there are no errors, and then perform multi axis linkage to avoid mechanical collisions; After debugging is completed, backup the parameter files for quick configuration recovery in case of module failure replacement.

Maintenance and Overhaul:

Regularly (every 6 months) inspect the appearance of the module, focusing on whether the terminals are loose or oxidized, and whether the LED indicator lights are normal; Clean the front-end connector and heat dissipation holes once a year, wipe them with a dry soft cloth, and prohibit the use of corrosive cleaning agents such as alcohol.

If the module experiences communication failure, no output signal or other faults, first check the power supply and wiring, replace the backup module for testing; It is prohibited to disassemble the module for maintenance by oneself. It is necessary to replace the module with the same model and recalibrate the analog input accuracy after replacement (such as connecting the standard 4mA/20mA signal and confirming that the collected value deviation is less than 0.5%).

Special working condition precautions:

When used in low temperature environments (<-10 ℃), small heating elements should be configured for the control cabinet to control the temperature inside the cabinet above -10 ℃, in order to avoid the failure of internal capacitors in the module due to low temperature; When used in high temperature environments (>55 ℃), install a small cooling fan to ensure that the surface temperature of the module does not exceed 60 ℃.

In scenarios with strong electromagnetic interference (such as near high-power frequency converters), it is necessary to install metal shielding covers for the modules and strengthen the shielding and grounding of signal cables to avoid interference causing signal acquisition distortion or erroneous output of control commands.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-