The ABB 500CPU03 1HDF700003R5122 central processing unit (hereinafter referred to as the "500CPU03 processor") is the core control unit in ABB's automation control system, belonging to its mainstream PLC (Programmable Logic Controller) product series. This processor is designed specifically for industrial automation scenarios, with high reliability, strong computing power, and flexible scalability. It can accurately achieve real-time monitoring, logical control, and data processing of complex industrial processes, and is a key component in building modern industrial control systems.

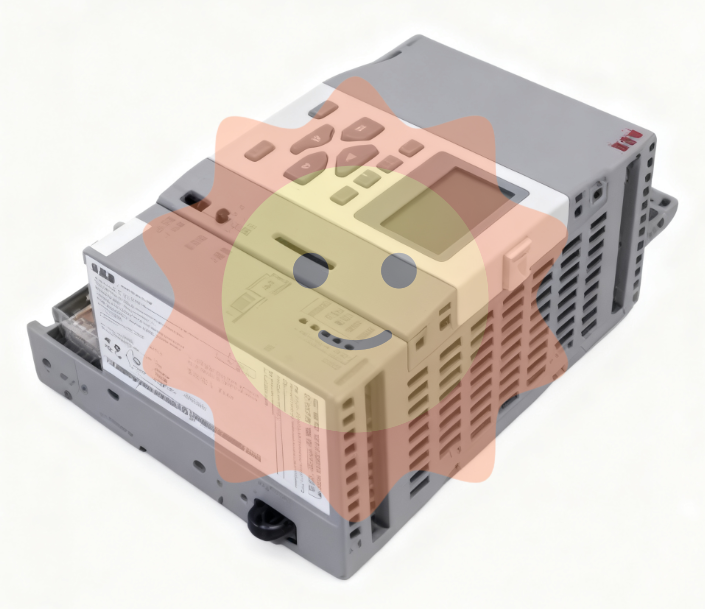

ABB 500CPU03 1HDF700003R5122 Central Processing Unit

Product Overview

The ABB 500CPU03 1HDF700003R5122 central processing unit (hereinafter referred to as the "500CPU03 processor") is the core control unit in ABB's automation control system, belonging to its mainstream PLC (Programmable Logic Controller) product series. This processor is designed specifically for industrial automation scenarios, with high reliability, strong computing power, and flexible scalability. It can accurately achieve real-time monitoring, logical control, and data processing of complex industrial processes, and is a key component in building modern industrial control systems.

As a core component launched by ABB for mid to high end industrial control needs, the 500CPU03 processor integrates advanced chip technology and industrial control algorithms, and can adapt to various application architectures from single machine automation to distributed control systems (DCS), providing a stable and reliable control core for automation upgrades in manufacturing, energy, transportation and other fields.

Core performance parameters

1. Computational ability

The 500CPU03 processor is equipped with a high-performance 32-bit microprocessor, with a processing speed of [XX] MIPS (million instructions per second), which can quickly handle complex logical operations, floating-point operations, and batch data processing tasks. For common scenarios such as sequential control and process control in industrial control, its built-in dedicated computing module can further improve the control response speed, ensure real-time control accuracy of on-site equipment, and the typical control cycle can be as low as milliseconds, meeting the strict response time requirements of high-speed production lines, precision manufacturing, and other scenarios.

2. Storage configuration

The processor is equipped with a large capacity built-in storage unit, with a program memory capacity of [XX] MB, supporting the storage of complex control programs, algorithm models, and process parameters; The data storage capacity is [XX] MB, which can cache real-time sensor data, device operating status, and other information collected on site. At the same time, it supports expanding storage capacity through external storage cards to meet the needs of long-term data recording, program backup, etc., ensuring the security and integrity of data storage.

3. Communication capability

In terms of communication interfaces, the 500CPU03 processor has a rich configuration, covering Ethernet interfaces, RS485/RS232 serial communication interfaces, etc., supporting mainstream industrial communication protocols such as PROFINET, Modbus, EtherNet/IP, etc. Through these interfaces, the processor can seamlessly connect with on-site IO modules, human-machine interfaces (HMI), upper monitoring systems, and other intelligent devices, building an efficient industrial communication network to ensure fast transmission and sharing of data throughout the entire control system. In addition, its support for redundant communication functions can further enhance the reliability of communication links and avoid system downtime caused by communication failures.

4. Reliability and stability

In response to the complex operating environment of industrial sites, the 500CPU03 processor adopts a high anti-interference design and has strong electromagnetic compatibility (EMC) capabilities, which can resist interference factors such as electromagnetic radiation and voltage fluctuations in industrial sites. Its working temperature range is wide up to -20 ℃~60 ℃, supporting stable operation in harsh temperature and humidity environments. At the same time, it has fault protection functions such as overcurrent, overvoltage, and short circuit, which can effectively protect the processor and the entire control system from damage. In addition, the processor supports hot swappable functionality (for some models), making it easy to maintain and replace without shutting down the system, significantly improving the system's continuous running time.

Applicable industries and scenarios

With its excellent performance and reliability, the 500CPU03 processor is widely used in multiple industrial fields, with typical application scenarios including:

-Manufacturing industry: used for automated control of production lines in automobile manufacturing, electronic equipment production, mechanical processing, etc., to achieve functions such as start stop control of production equipment, process linkage, and quality inspection data collection, improving production efficiency and product quality.

-Energy industry: In the fields of power generation (thermal power, hydropower, new energy), petrochemicals, coal mining, etc., it is used for parameter monitoring (such as temperature, pressure, flow), equipment control (such as pumps, valves, fans), and energy consumption statistics in the energy production process, ensuring the safety, efficiency, and stability of energy production.

-In the field of transportation, it is applied to rail transit signal systems, port loading and unloading equipment, intelligent transportation control systems, etc., to achieve precise control and scheduling of transportation equipment, and ensure the orderly and safe operation of transportation.

-Municipal engineering: used for the automation control of municipal facilities such as sewage treatment, water supply systems, and urban lighting, achieving remote monitoring and intelligent adjustment of municipal equipment, and improving the efficiency and intelligence level of municipal services.

Key points for installation and maintenance

1. Installation requirements

During installation, the processor should be fixed on a standard DIN rail to ensure a secure installation and avoid vibration affecting the equipment; The installation location should be far away from strong magnetic fields, high-temperature heat sources, and areas that are prone to dust and corrosive gases. At the same time, sufficient heat dissipation space should be left around the equipment to ensure good heat dissipation. When wiring, it is necessary to strictly follow the requirements of the product manual to ensure that the power polarity is correct and the communication line is firmly connected, in order to avoid equipment damage or communication failures caused by wiring errors.

2. Daily maintenance

During daily maintenance, it is necessary to regularly check the operating status of the processor, and monitor the power, communication, and operating status of the equipment through indicator lights or the upper system; Regularly clean the dust on the surface of the equipment and keep the cooling vents unobstructed; For stored programs and data, regular backups should be made to prevent data loss due to device failures. When the equipment malfunctions, the fault diagnosis function should be used to locate the cause of the fault first, and then targeted maintenance or replacement should be carried out to avoid blind operation.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-