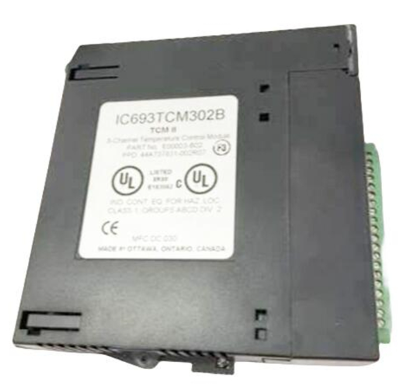

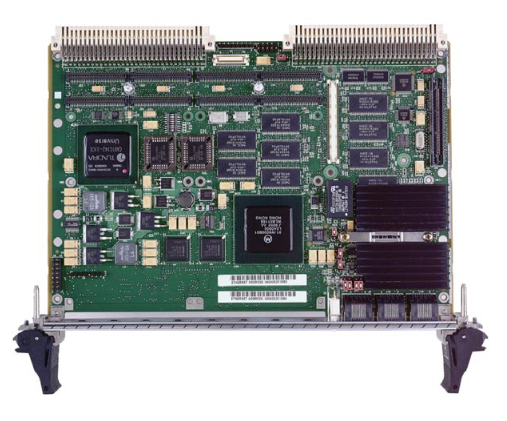

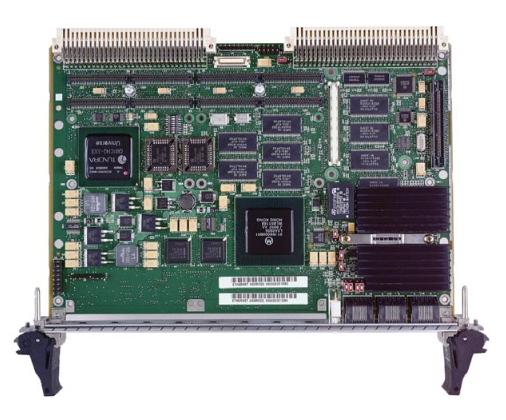

ABB 216AB61 HESG216881 Advanced Industrial Control Module

ABB 216AB61 HESG216881 Advanced Industrial Control Module

Overview

The ABB 216AB61 HESG216881 is an advanced industrial control module designed to provide high - level control and management capabilities in complex industrial settings. It serves as a key component in optimizing industrial processes and ensuring the efficient operation of machinery and systems.

Functionality and Features

Sophisticated Control Algorithms

The module is equipped with a wide range of advanced control algorithms. It can handle complex control strategies such as model - predictive control (MPC), adaptive control, and non - linear control. These algorithms allow for precise regulation of industrial processes. For example, in a chemical plant, MPC implemented in this module can anticipate changes in process variables like temperature and pressure based on a mathematical model of the chemical reaction and adjust the control parameters proactively to maintain optimal operating conditions.

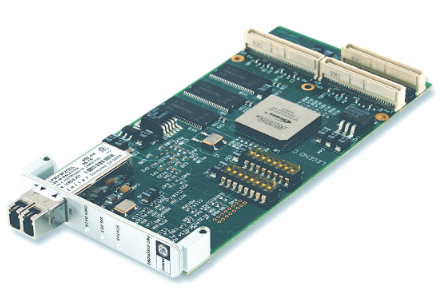

High - Speed Data Processing

It offers high - speed data - processing capabilities. The module can quickly analyze and process large amounts of data received from various sensors and other input sources. This includes both digital and analog data representing parameters such as flow rates, temperatures, and equipment status. The rapid data processing enables real - time decision - making and control actions. For instance, in a high - speed manufacturing process, it can process data from multiple sensors monitoring the production line to detect and correct any deviations from the desired production parameters almost instantaneously.

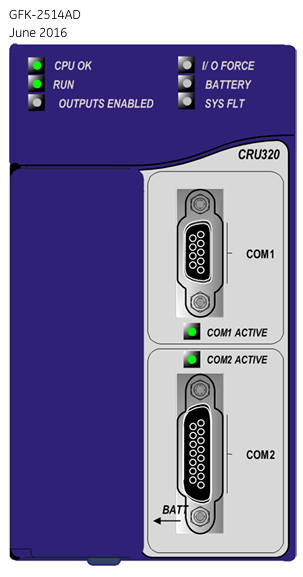

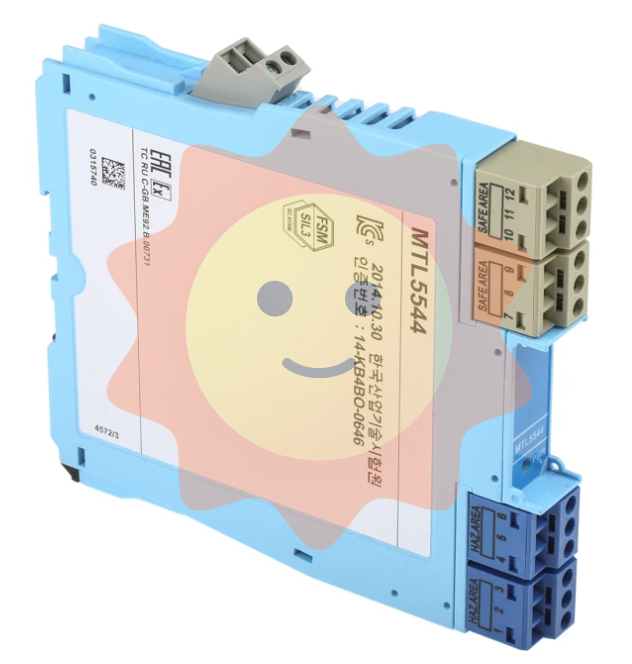

Multiple Communication Interfaces

The 216AB61 HESG216881 module provides multiple communication interfaces to interact with other components in the industrial system. It supports standard protocols such as Ethernet/IP, Profibus - DP, and Modbus - TCP. These interfaces allow it to communicate with Programmable Logic Controllers (PLCs), Human - Machine Interfaces (HMIs), remote I/O (Input/Output) modules, and other control systems. This enables seamless integration into existing industrial automation architectures and facilitates the exchange of control commands, status updates, and process - data.

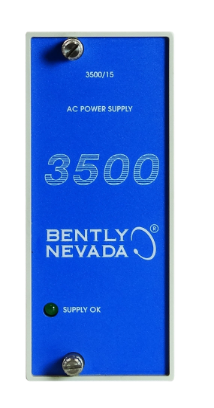

Redundancy and Fault - Tolerance Features

To ensure the reliability of industrial processes, the module incorporates redundancy and fault - tolerance features. It can have redundant communication paths or backup power - supply options. In case of a component failure, such as a communication - interface failure or a power - supply interruption, the module can switch to a backup mode or raise an alarm to alert the maintenance personnel. This fault - tolerant design helps to minimize downtime and maintain the continuity of critical industrial operations.

Technical Specifications

Processor and Memory

The module is powered by a high - performance processor with a specific clock speed and processing capacity. The processor's performance is crucial for executing the complex control algorithms and handling the high - speed data - processing tasks. It also has a significant amount of memory, including both random - access memory (RAM) and non - volatile memory such as flash memory. The RAM is used for temporary data storage during operation, while the flash memory stores the control programs, configuration settings, and historical data for backup and retrieval purposes.

Input and Output Capabilities

The 216AB61 HESG216881 has a diverse set of input and output channels. The input channels can handle a wide range of digital and analog signals. For digital inputs, it can accept signals with different voltage levels such as TTL (Transistor - Transistor Logic) and CMOS (Complementary Metal - Oxide - Semiconductor). The analog input channels have specific voltage and current ranges to interface with various industrial sensors. The output channels can generate digital and analog output signals to control actuators such as relays, motors, and valves. The output signals have appropriate voltage and current characteristics to drive the connected devices effectively.

Operating Temperature and Environmental Tolerance

The control module is designed to operate in a wide range of environmental conditions. It typically has an operating temperature range from - 20°C to +60°C, which makes it suitable for most industrial environments. It also has good resistance to humidity, vibration, and electromagnetic - interference (EMI). These environmental - tolerance features ensure its reliable performance in harsh industrial settings such as factories, power plants, and chemical plants.

Applications

Process Industries

In the chemical, pharmaceutical, and petrochemical industries, the ABB 216AB61 HESG216881 module is used to control complex chemical reactions and separation processes. It can optimize the operation of reactors, distillation columns, and heat - exchangers by implementing advanced control strategies. For example, in a pharmaceutical manufacturing process, it can precisely control the temperature, pressure, and agitation speed in a reaction vessel to ensure the quality and consistency of the product.

Power Generation and Distribution

In power - generation and - distribution systems, the module is used to manage the operation of generators, transformers, and power - switching equipment. It can monitor and control power - generation parameters such as voltage, current, and frequency. It also plays a role in grid - connection and power - dispatch operations, ensuring the stability and reliability of the power - supply system. For instance, it can adjust the output of a generator based on the load demand and grid - frequency requirements.

Industrial Automation and Robotics

In industrial automation and robotics, the module is used to control the movement and operation of robots and automated production lines. It can implement kinematic and dynamic control algorithms to ensure the precise positioning and motion of robotic arms. It also interfaces with sensors to provide feedback - controlled operation, enhancing the accuracy and efficiency of robotic tasks such as assembly, welding, and material - handling.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com