ABB TB840A 3BSE037760R1 is a modular cluster modem designed for industrial remote communication scenarios, belonging to the communication hardware family of ABB Advant OCS and 800xA control systems. As a "bridge" for remote data transmission in industrial control networks, this device integrates core capabilities such as cluster communication, multi protocol adaptation, signal enhancement, and redundant backup. It is specifically designed to solve the problem of remote data exchange between dispersed equipment and central control systems in industrial sites, and is widely used in fields such as oil and gas extraction, mining and metallurgy, urban pipeline networks, remote power stations, etc., which have strict requirements for communication stability, anti-interference, and environmental adaptability. Its modular design and high reliability provide stable and efficient communication support for industrial remote monitoring, data acquisition, and control instruction transmission.

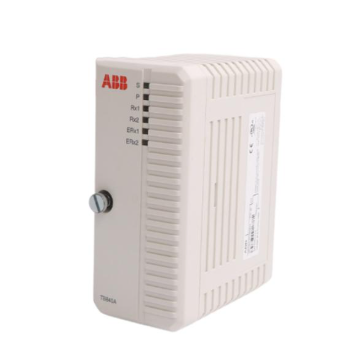

ABB TB840A 3BSE037760R1 modular cluster modem

ABB TB840A 3BSE037760R1 is a modular cluster modem designed for industrial remote communication scenarios, belonging to the communication hardware family of ABB Advant OCS and 800xA control systems. As a "bridge" for remote data transmission in industrial control networks, this device integrates core capabilities such as cluster communication, multi protocol adaptation, signal enhancement, and redundant backup. It is specifically designed to solve the problem of remote data exchange between dispersed equipment and central control systems in industrial sites, and is widely used in fields such as oil and gas extraction, mining and metallurgy, urban pipeline networks, remote power stations, etc., which have strict requirements for communication stability, anti-interference, and environmental adaptability. Its modular design and high reliability provide stable and efficient communication support for industrial remote monitoring, data acquisition, and control instruction transmission.

Core Features and Advantages

1. Modular architecture and flexible configuration

The equipment adopts standardized modular design, supporting independent plugging and combination configuration of power module, communication module, and signal processing module. Users can flexibly select cellular communication modules such as GPRS/4G/LTE or wired communication modules such as RS485/RS232 based on communication distance, data volume, and on-site environmental requirements. Up to 4 communication sub modules can be expanded to achieve a "one device, multiple links" communication architecture. This design not only reduces initial procurement costs, but also facilitates module replacement according to network upgrade requirements in the later stage, without the need for overall equipment replacement, improving asset utilization.

2. Cluster communication and multi link redundancy

As a core highlight, this device supports cluster communication technology and can be connected to industrial dedicated cluster networks to achieve multicast communication and data synchronization among multiple devices. It is suitable for centralized data collection in decentralized industrial scenarios, such as oil and gas field wellhead equipment groups and mining equipment. At the same time, the device has multi link redundancy function. When the main communication link (such as 4G) experiences signal interruption or interference, it can automatically switch to the backup link (such as GPRS or wired link) with a switching time of ≤ 500ms, ensuring the continuity of remote communication and avoiding control failure or data loss caused by communication interruption.

3. Industrial grade anti-interference and signal optimization

In response to the complex electromagnetic environment of industrial sites, the equipment is equipped with high-performance signal filtering circuits and electromagnetic shielding modules. It has passed IEC 61000-6-2/3 anti-interference certification and can effectively resist electromagnetic radiation and pulse interference generated by high-voltage equipment, frequency converters, etc. Equipped with a high gain external antenna interface, it supports 360 ° signal reception. In weak signal environments such as remote mountainous areas and underground mines, the signal strength can be enhanced through an external directional antenna to ensure the stability of the communication link. The data transmission adopts AES 256 bit encryption algorithm to prevent data from being stolen or tampered with during transmission, ensuring industrial data security.

4. Wide temperature range adaptation and high reliability

Adopting industrial grade reinforced components and sealed casing design, it has undergone rigorous environmental adaptability testing and can operate stably in extreme temperature ranges of -40 ℃~70 ℃ and humid environments of 5%~95% humidity (without condensation). The device supports overvoltage, overcurrent, short circuit, and surge protection, with a wide power input range of 10V~36V DC, which can adapt to unstable power supply environments in industrial sites. The mean time between failures (MTBF) exceeds 80000 hours, meeting the low maintenance needs of equipment in remote industrial scenarios.

5. Convenient management and remote diagnosis

Support parameter configuration and status monitoring through ABB Communication Studio dedicated software, providing a graphical user interface for engineers to quickly set communication protocols, link priorities, data transmission cycles, and other parameters. The equipment has remote diagnostic function, which can upload its own operating status (such as power supply voltage, module temperature, signal strength, link quality) to the central control system in real time. When a fault occurs, it can notify the operation and maintenance personnel in a timely manner through SMS, email or system alarm, achieving rapid fault location and remote troubleshooting, and reducing on-site maintenance costs.

Key technical parameters

Basic Information

model

TB840A 3BSE037760R1

Basic Information

affiliated system

ABB Advant OCS/800xA Control System

Modular configuration

Module slot/type

4 standard slots, supporting GPRS/4G/LTE/RS485/RS232 modules

Communication performance

Cellular communication frequency band

4G:TD-LTE/FDD-LTE; GPRS:GSM 850/900/1800/1900MHz

Communication performance

Data transmission rate

4G: downstream ≤ 150Mbps, upstream ≤ 50Mbps; GPRS:≤115.2kbps

Communication performance

Supported Protocols

Modbus RTU/TCP、TCP/IP、UDP、PPP、HTTP、MQTT

Communication performance

interface type

2 RJ45 Ethernet ports, 4 module expansion interfaces, and 1 antenna interface (SMA)

redundant function

Link redundancy/switching time

Support multi link automatic redundancy; Switching time ≤ 500ms

Power requirements

Input voltage/power consumption

10V~36V DC; Maximum power consumption ≤ 20W (full module operation)

environmental parameters

Working temperature/humidity

-40℃~70℃; 5%~95% (no condensation)

environmental parameters

Protection level/vibration resistance

IP30 (main body); ≤3g(10Hz~500Hz)

security features

Data encryption/protection function

AES 256 bit encryption; Overvoltage, overcurrent, and short-circuit protection

physical properties

Installation method/size

DIN rail installation; 150mm x 100mm x 80mm (length x width x height)

reliability index

Mean Time Between Failures (MTBF)

≥ 80000 hours

Typical application scenarios

1. Oil and gas extraction industry: remote monitoring of remote wellheads

In remote wellheads of oil and gas fields, as well as scattered scenes along oil pipelines, on-site sensor data such as pressure, temperature, and flow rate need to be uploaded in real-time to the central control room, but these areas often lack wired communication network coverage. The TB840A modem constructs a redundant communication link by selecting 4G+GPRS dual communication modules, encrypts wellhead equipment data, and transmits it to the 800xA control system. When the 4G signal weakens due to terrain obstruction, it automatically switches to the GPRS link to ensure uninterrupted data. Operation and maintenance personnel can monitor the communication status of equipment in real-time through remote diagnostic functions, eliminating the need for frequent on-site visits and significantly reducing operation and maintenance costs.

2. Mining and metallurgical industry: underground mining communication guarantee

In underground mining areas such as mining sites and tunnels, the environment is humid, electromagnetic interference is strong, and signal shielding is severe, making it difficult for traditional communication equipment to work stably. TB840A is designed with a wide temperature range of -40 ℃~70 ℃ and an IP30 protection level, making it suitable for harsh underground environments. By using an external directional antenna to enhance signal penetration, RS485 modules are connected to mining sensors and actuators to transmit data such as gas concentration, roof pressure, and equipment operation status from the mining area to the ground monitoring center through a cluster communication network. This enables remote control and safety warning of underground equipment, ensuring the safety of mining production.

3. Urban pipeline network industry: distributed station data collection

In the distributed monitoring stations of urban water, gas, and heat pipelines, a large number of dispersed pressure sensors and flow meters need to communicate with the dispatch center. TB840A matches the optimal communication solution for different regional sites through modular configuration: urban sites use 4G modules for high-speed data transmission, suburban remote sites use GPRS modules to reduce costs, and some short-range sites can form wired networks through RS485 modules. The device supports MQTT protocol and can be directly connected to the urban smart pipeline platform to achieve functions such as pipeline leakage monitoring and pressure regulation, thereby improving the operational efficiency of the urban pipeline network.

4. Power and energy industry: Communication and interconnection of remote power stations

In remote areas such as photovoltaic power stations, small hydropower stations, and substations, it is necessary to transmit power generation data and equipment status information to the power grid dispatch center. TB840A adopts a dual power redundant input design to adapt to the unstable power supply environment of the power station. It uses 4G/LTE modules to achieve high-speed uploading of power generation data and supports interconnection with the PLC and SCADA systems of the power station. The transmitted data includes power generation, voltage, current, equipment fault information, etc. The multi link redundancy function ensures that data transmission is not interrupted in the event of a communication link interruption caused by extreme weather, ensuring the accuracy of power grid scheduling and the stability of power station operation.

Installation and usage precautions

-The equipment should be installed in a ventilated, dry, and non corrosive gas environment. Outdoor installation should be equipped with a waterproof and sun protection control cabinet to ensure that the protection level is raised to IP54 or above. The installation location should be away from strong interference sources such as high-voltage cables and frequency converters. The antenna installation should avoid obstructions to ensure good signal reception.

-Before wiring, it is necessary to confirm that the voltage range of the power supply is consistent with the equipment requirements. The power supply line should use copper core wires and be equipped with fuses. The communication line should distinguish the positive and negative poles of the signal to avoid module damage caused by reverse connection. The RS485 bus needs to use shielded twisted pair cables, with the shielding layer grounded at one end. The Ethernet line needs to be made with crystal heads according to the T568B standard.

-Before configuring the module, it is necessary to establish a connection with the device through ABB Communication Studio software, select the appropriate communication module according to communication requirements, and configure parameters such as link priority, data transmission cycle, encryption key, etc. After configuration, communication testing is required to ensure normal data transmission.

-Before putting the equipment into operation, it is necessary to check whether the antenna connection is secure, whether the power supply is stable, and whether the module is properly recognized. Regularly monitor signal strength, link quality, module temperature and other parameters through software during operation. Perform dust removal maintenance on the equipment every six months and check the tightness of the wiring terminals.

-When replacing the communication module, the device power should be cut off first, and excessive force should be avoided when plugging and unplugging the module to prevent damage to the slot. Firmware upgrade requires obtaining upgrade files through official channels, strictly following the upgrade process, avoiding power outages during the upgrade process, and preventing device bricking.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-