ABB BDD110 HNLP205879R1 is an industrial grade high-performance digital input/output integrated module, belonging to ABB's automation control module product series. It is mainly used for real-time acquisition (input) of digital signals in industrial fields and execution and output (output) of control instructions. This module adopts a standardized modular design, supporting seamless integration with mainstream ABB PLCs (such as AC800M, AC500 series) and DCS systems, while also being compatible with third-party control devices that comply with industrial communication protocols. Its input channel can be directly connected to on-site digital sensors such as buttons, travel switches, proximity switches, etc. The output channel can drive actuators such as relays, solenoid valves, indicator lights, etc., achieving efficient control of discrete signals in industrial production processes and widely applicable to various automation control scenarios.

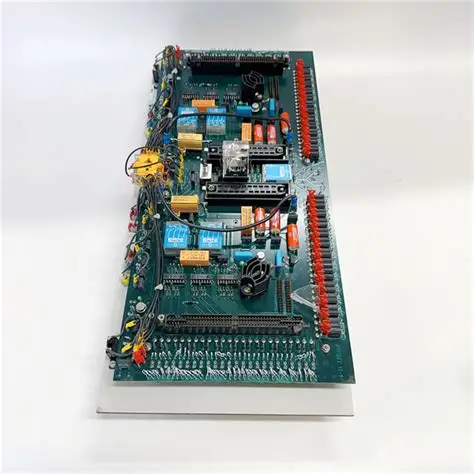

ABB BDD110 HNLP205879R1 Digital I/O Module

Basic overview of module

ABB BDD110 HNLP205879R1 is an industrial grade high-performance digital input/output integrated module, belonging to ABB's automation control module product series. It is mainly used for real-time acquisition (input) of digital signals in industrial fields and execution and output (output) of control instructions. This module adopts a standardized modular design, supporting seamless integration with mainstream ABB PLCs (such as AC800M, AC500 series) and DCS systems, while also being compatible with third-party control devices that comply with industrial communication protocols. Its input channel can be directly connected to on-site digital sensors such as buttons, travel switches, proximity switches, etc. The output channel can drive actuators such as relays, solenoid valves, indicator lights, etc., achieving efficient control of discrete signals in industrial production processes and widely applicable to various automation control scenarios.

Core performance characteristics

1. High integration and flexible channel configuration

This module adopts a highly integrated circuit design, integrating multiple sets of digital input and output channels within a compact external size. The typical configuration is 16 digital inputs and 8 digital outputs (depending on the actual model). The input and output channels are independently isolated and can be configured for different types of on-site signals. The input channel supports multiple signal types such as dry contacts and wet contacts, while the output channel provides two optional modes: relay output and transistor output. The relay output can directly drive high-power loads, while the transistor output is suitable for high-frequency switch control scenarios. Users can flexibly choose according to their actual control needs, greatly improving the applicability of the module.

2. Fast signal response and real-time control capability

To meet the real-time control requirements of industrial sites, the module adopts high-speed signal processing chips, and the response time of the digital input channel is as short as 1ms, which can quickly capture the status changes of on-site equipment and avoid control errors caused by signal delays; The action response time of the output channel is also optimized to the microsecond level, which can execute instructions issued by the control core in a timely manner, ensuring that the actions of the controlled device are synchronized with the control logic. In addition, the module supports interrupt triggering function. When there is an abnormal jump in the input signal, an interrupt request can be immediately sent to the control core to achieve priority processing of critical signals, further improving the real-time control performance of the system.

3. Excellent anti-interference and reliability design

In response to the complex electromagnetic environment of industrial sites, the module has constructed a comprehensive anti-interference system from both hardware and software aspects. In terms of hardware, both input and output channels adopt optoelectronic isolation technology, with an isolation voltage of up to 2500Vrms, which can effectively resist electromagnetic interference generated by on-site equipment start stop, high-power motor operation, etc., and prevent interference signals from entering the control core and affecting system stability; At the same time, the module is equipped with overvoltage and overcurrent protection circuits, which can quickly cut off the output circuit when the output channel load is abnormal or a short circuit occurs, protecting the module and controlled equipment from damage. On the software side, there is a built-in signal filtering algorithm that can perform anti shake and noise filtering on the input signal to ensure the authenticity and reliability of the collected signal.

4. Convenient diagnostic and operational functions

The module has complete self diagnosis and fault alarm functions, which can monitor its own working status, channel connection status, and signal integrity in real time. Through the LED status indicator lights on the surface of the module, operation and maintenance personnel can intuitively judge the working status of each input and output channel (such as whether there is an input signal, whether the output is active, channel faults, etc.); At the same time, the module can upload diagnostic information (such as channel faults, power supply abnormalities, etc.) to the control core or upper monitoring system through the communication interface, achieving remote monitoring and positioning of faults. In addition, the module supports online hot plugging function (with system support), which can complete module replacement and maintenance without interrupting the operation of the entire control system, greatly reducing fault handling time.

5. Powerful communication compatibility and scalability

The module supports multiple mainstream industrial communication protocols, including PROFINET, EtherNet/IP, Modbus TCP, etc., making it easy to integrate into automation systems with different communication architectures without the need for additional dedicated communication modules. At the same time, the module adopts a standardized rack mounted installation method, supporting collaborative work with other modules in the same series as ABB (such as analog I/O modules and communication modules). By expanding the rack, centralized control of multiple modules can be achieved, meeting the processing requirements of large-scale automation systems for multi-channel and multi type signals, and improving the integration efficiency and scalability of the system.

Key technical parameters

parameter category

Specific parameters

power input

DC 24V ± 10%, typical power consumption ≤ 5W

Digital input channel

16 channels, supporting dry/wet contact signals, input voltage DC 10-30V

Input response time

≤ 1ms (configurable through software)

Input isolation method

Optoelectronic isolation, isolation voltage 2500Vrms (between channels and between channels and ground)

Digital output channel

8 channels, relay output (optional transistor output), rated current 2A/250VAC per channel

Output response time

Relay output ≤ 10ms, transistor output ≤ 100 μ s

Output protection function

Overcurrent protection, short circuit protection

communication interface

1 Ethernet interface, supporting PROFINET/EtherNet/IP/Modbus TCP

Working environment temperature

-20 ℃~65 ℃ (no condensation)

Working environment humidity

5%~95% RH, No condensation

Protection level

IP20 (module body), compatible with control cabinets up to IP65

Installation method

35mm DIN rail installation, supports hot swapping (when compatible with the system)

Dimensions (W × H × D)

45mm × 140mm × 120mm (typical value, subject to actual product)

Applicable scenarios

The ABB BDD110 HNLP205879R1 digital I/O module, with its flexible configuration, stable performance, and strong compatibility, is widely used in various industrial automation control scenarios and has become the core component connecting field devices and control cores. Its main application areas include:

1. Intelligent manufacturing and production line control: Used in scenarios such as automotive welding production lines, electronic component assembly lines, food packaging production lines, etc., it is used to collect conveyor belt position signals, workpiece detection signals, equipment operation status signals, etc., and output instructions to control the action of robotic arms, conveyor belt start stop, solenoid valve switch, etc., achieving automated collaboration and precise control of production processes, and improving production efficiency.

2. Mechanical manufacturing and equipment control: In CNC machine tools, printing machinery, injection molding machines and other equipment, it is used to collect travel limit signals, emergency stop button signals, temperature switch signals, etc. of the equipment, output control signals to drive the equipment's motors, hydraulic valves, indicator lights, etc., to ensure the safe and stable operation of the equipment and achieve automated operation of the equipment.

3. Power system automation: In the automation monitoring system of substations and distribution rooms, it is used to collect the opening and closing status signals of circuit breakers, isolation switches, cabinet door switch signals, temperature and humidity sensor signals, etc., output signals to control indicator lights, alarm devices, small fans, etc., to achieve real-time monitoring and auxiliary control of power equipment status.

4. Chemical and process industries: In chemical production workshops and petroleum refining facilities, it is used to collect valve switch status, pump operation signals, safety interlock signals, etc., output control signals to drive solenoid valves, alarm lights, and other equipment, and cooperate with the control core to achieve interlocking control of the production process, ensuring the safety and stability of the production process.

5. Building automation and intelligent buildings: In the security system and HVAC system of intelligent buildings, it is used to collect access control switch signals, infrared detection signals, fan operation status, etc., output signals to control door locks, lighting, air conditioning units and other equipment, and achieve automatic control and energy-saving operation of building equipment.

6. Water treatment and environmental protection industry: In sewage treatment plants and water treatment plants, it is used to collect the operating status of water pumps, liquid level switch signals, valve opening and closing status, etc., output control signals to drive the start and stop of water pumps, valve action, etc., to achieve automatic control of water treatment processes, improve water treatment efficiency and water quality compliance rate.

5、 Core advantages of the module

-Stable signal transmission and precise control: The high-speed signal response capability and perfect anti-interference design ensure real-time acquisition of on-site signals and accurate execution of control instructions, avoiding control errors caused by signal delay or interference, and improving the control accuracy of the system.

-High reliability and long lifespan: Industrial grade high stability components are used, which have undergone rigorous environmental adaptability testing and aging testing. The mean time between failures (MTBF) is ≥ 120000 hours, allowing for long-term stable operation in harsh industrial environments and reducing equipment maintenance costs.

-Flexible configuration and strong adaptability: Multi channel configuration and support for multiple signal types can meet the control needs of different scenarios; Simultaneously compatible with multiple communication protocols and control devices, it can be integrated into existing systems without the need for large-scale modifications, improving system upgrade and integration efficiency.

-Convenient operation and maintenance, easy to handle faults: intuitive status indicators and comprehensive fault diagnosis functions can quickly locate channel faults, communication abnormalities, and other issues; Support hot swapping function (when compatible with the system), greatly reducing fault handling time and minimizing system downtime losses.

-Brand guarantee and comprehensive service: Relying on ABB's global comprehensive technical support and after-sales service system, we can provide users with professional installation guidance, technical consultation, and fault repair services to ensure the stable operation of modules and reliable control of the system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-