ABB CI535V26 (order number 3BSE022161R1) is a key communication hub equipment in ABB AC 800M series DCS (Distributed Control System), designed for high-speed data exchange of multiple devices and protocols in industrial automation scenarios. As a "bridge" between the controller and external devices, this module achieves seamless integration between the control system and field instruments, actuators, third-party PLCs, monitoring systems, and other equipment through standardized communication protocols and flexible interface configurations, providing stable and reliable communication support for data collection, instruction transmission, and system collaboration in industrial production processes.

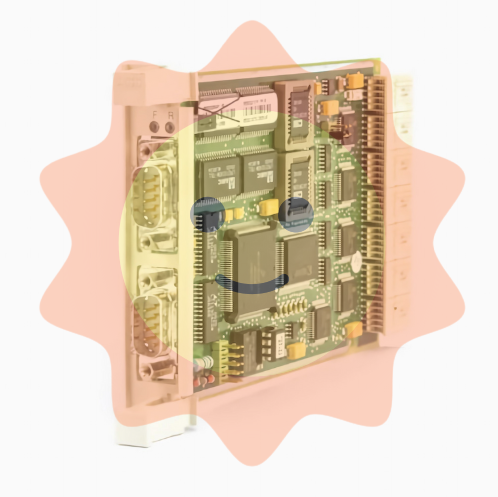

ABB CI535V26 3BSE022161R1 Communication Interface Module

Module Overview

ABB CI535V26 (order number 3BSE022161R1) is a key communication hub equipment in ABB AC 800M series DCS (Distributed Control System), designed for high-speed data exchange of multiple devices and protocols in industrial automation scenarios. As a "bridge" between the controller and external devices, this module achieves seamless integration between the control system and field instruments, actuators, third-party PLCs, monitoring systems, and other equipment through standardized communication protocols and flexible interface configurations, providing stable and reliable communication support for data collection, instruction transmission, and system collaboration in industrial production processes.

Its core positioning is to solve problems such as heterogeneous communication protocols, data transmission delays, and poor device compatibility in industrial sites. It is widely used in industries such as power, chemical, metallurgical, and municipal that require complex communication link construction. It is a core component that ensures the real-time and integrity of control system information exchange.

Core functions and technological advantages

2.1 Core Functions

-Multi protocol compatible communication: The core supports PROFIBUS DP V1/V2 protocol, and can also be adapted to PROFIBUS PA through software configuration (via coupler) to achieve bidirectional data exchange with field devices of different protocol types, meeting the communication needs of heterogeneous industrial networks.

-High speed data transmission: The communication rate can be adaptively adjusted between 9.6kbps-12Mbps according to on-site requirements, supporting up to 12Mbps high-speed transmission mode. A single module can connect up to 126 slave devices, ensuring real-time synchronization of large amounts of data.

-Flexible master-slave configuration: Supports dual working modes of PROFIBUS DP master and slave, and can quickly configure working modes and communication parameters through ABB Control Builder M software, adapting to various communication architectures such as "controller slave device" and "controller third-party controller".

-Communication status monitoring and diagnosis: Equipped with comprehensive communication diagnostic functions, it can monitor key parameters such as bus voltage, communication link connection status, and data transmission error rate in real time. When problems such as disconnection, slave station failure, and data loss occur, an alarm is immediately triggered and diagnostic information is uploaded to the controller.

-Data caching and breakpoint retransmission: Equipped with an independent data caching unit, when the communication link is temporarily interrupted and restored, it can automatically retransmit cached critical data to avoid control system decision bias caused by data loss.

2.2 Technical advantages

-High compatibility and scalability: Perfectly compatible with various models of ABB AC 800M controllers, supporting seamless integration with ABB S400 I/O modules, AC 500 series PLCs, and third-party PROFIBUS compatible devices without the need for additional protocol conversion modules, reducing system integration costs.

-Industrial grade stability design: adopting anti electromagnetic interference (EMC) enhanced design, complying with IEC 61000-6-2 industrial anti-interference standard, which can resist interference factors such as electromagnetic radiation and voltage fluctuations in industrial sites; The module adopts an isolation protection circuit internally to avoid the impact of bus faults on the controller.

-Convenient configuration and maintenance: Visual configuration of module parameters can be achieved through Control Builder M software, supporting online modification of communication parameters and real-time effectiveness; The module comes with status indicator lights (power, communication, fault), which can quickly locate hardware or link faults.

-Redundant communication support: It can form a redundant communication link with modules of the same model. When the main communication module or bus fails, it automatically switches to the backup link to ensure the continuity of the communication link. It is suitable for critical control links that require extremely high communication reliability.

Key technical parameters

Core agreement

PROFIBUS DP V1/V2, Compatible with PROFIBUS PA (coupler required)

Covering mainstream industrial fieldbus protocols and adapting to various types of devices

communication rate

9.6kbps - 12Mbps, Adaptive adjustment

Flexible selection based on bus length and number of devices, balancing speed and stability

Maximum number of slave stations

126 (PROFIBUS DP mode)

Support large-scale device networking and reduce the number of modules used

working mode

PROFIBUS DP master and slave, software switchable

Adapt to different communication architecture requirements and enhance networking flexibility

power supply

24V DC ± 10%, typical current ≤ 150mA

Wide voltage input, adaptable to power fluctuations in industrial sites

Operating Temperature

-25℃ - +60℃

Adapt to harsh industrial environments with high and low temperatures

Storage temperature

-40℃ - +85℃

Meet the requirements of transportation and inventory environment

communication interface

2 RS485 interfaces (PROFIBUS DP) with isolation protection

Support redundant bus connections to enhance link reliability

module size

100mm (width) × 140mm (height) × 180mm (depth)

Compact design, saving installation space for control cabinets

EMC standard

Compliant with IEC 61000-6-2 (anti-interference in industrial environments)

Resist electromagnetic interference and ensure communication stability

Applicable scenarios

The CI535V26 module, with its multi protocol compatibility, high-speed transmission, and high reliability, is mainly used in industrial scenarios that require the construction of complex communication networks. Typical applications include:

1. Power industry: Communication between the DCS system of thermal power plant units and intelligent instruments such as temperature, pressure, and flow on site, and data exchange between substation monitoring systems, relay protection devices, and intelligent circuit breakers. The high-speed transmission capability of the module ensures real-time uploading of unit operating parameters, providing timely data support for scheduling decisions.

2. Chemical industry: The communication between the centralized control system of the chemical park and the PLC, regulating valve, liquid level gauge and other equipment of each production device, realizes the integration and centralized control of production data across devices. Its anti-interference design can adapt to the complex electromagnetic environment of chemical sites and ensure stable communication.

3. Metallurgical industry: The DCS system of production units such as blast furnaces and converters in steel plants communicates with weighing instruments, infrared thermometers, frequency converters, and other equipment to achieve real-time collection of production process parameters and accurate issuance of control instructions. The multi site support capability can meet the networking needs of a large number of equipment in metallurgical sites.

4. Municipal engineering: The SCADA system of sewage treatment plants and water treatment plants communicates with water pumps, valves, and water quality monitoring instruments to build a remote monitoring network covering the entire municipal pipeline network. Redundant communication support can ensure the continuity of municipal services and avoid service interruptions caused by communication failures.

5. Automotive manufacturing industry: The control system of the automotive final assembly production line communicates with robots, conveyor lines, and testing equipment to achieve automated collaboration in the production process. The high-speed communication capability can meet the high-frequency data exchange requirements of the production line and improve production efficiency.

Key points for installation and maintenance

5.1 Installation specifications

-The module needs to be installed in a control cabinet that meets the IP20 protection level, avoiding direct contact with dust, water vapor, and corrosive gases; The control cabinet should have good ventilation and heat dissipation conditions to ensure that the operating temperature of the module does not exceed 60 ℃.

-Adopting a guide rail installation method, with module spacing reserved at ≥ 10mm for easy heat dissipation and later maintenance; The installation location should be far away from strong electromagnetic interference sources such as high-power contactors and frequency converters to reduce the impact of interference on communication.

-The communication bus wiring needs to use PROFIBUS dedicated shielded twisted pair cables, with the shielding layer grounded at one end (grounding resistance ≤ 4 Ω); The bus length needs to match the communication rate (such as a maximum bus length of 100m at 12Mbps), and if it exceeds the length, a repeater needs to be installed.

-When configuring redundant communication, the communication interfaces of the main and backup modules need to be connected to two independent PROFIBUS buses, and terminal resistors (120 Ω) need to be installed at both ends of the bus to ensure impedance matching and reduce signal reflection.

-When wiring, it is necessary to distinguish between power terminals and communication terminals, and the positive and negative poles of the power supply must not be reversed; The sequence of communication lines A and B should be consistent with the slave equipment to avoid communication failures caused by incorrect line sequence.

5.2 Maintenance Suggestions

-Regular status check: Check the module status indicator light every week (the power light is always on and the communication light is flashing normally), check the communication error rate, slave online status and other parameters through the Control Builder M software, and promptly troubleshoot any abnormalities found.

-Bus link maintenance: Check the connection tightness of the communication bus every month and clean the dust at the wiring terminals; Measure the bus voltage with a multimeter every quarter (normally 2.5V-3.5V) to determine if there is a short circuit or poor contact on the bus.

-Software parameter backup: After module configuration is completed, promptly backup communication parameter configuration files; When a module malfunctions and needs to be replaced, configuration parameters can be quickly imported to shorten the recovery time.

-Fault handling process: When communication interruption occurs, first check whether the power supply is normal, and then investigate the bus connection and terminal resistance; If there is a communication failure in a single slave station, focus on checking the address configuration and wiring of that slave station; If all slave communication is interrupted, it is necessary to check whether there is a short circuit in the module itself or the bus.

-Environmental control: Keep the control cabinet dry and clean, and ensure the normal operation of the cooling fan during high temperature seasons; In humid environments, moisture-proof and dehumidification devices can be installed to prevent damage to the internal circuits of the module caused by moisture.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-