These two communication interface boards are both part of the GE Mark VIe or related series of industrial control platforms. As the "communication bridge" of the system, their core function is to solve communication compatibility issues between different devices, modules, and control systems. They can achieve bidirectional data exchange between on-site devices (such as sensors and actuators) and control units (such as CPU modules), as well as upper computer systems, transmitting dispersed device data to the control core and accurately issuing control instructions to execution terminals, ensuring the synergy and real-time performance of the entire industrial control process.

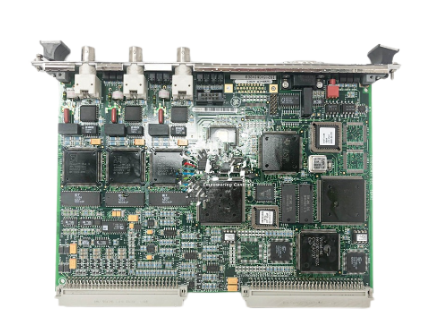

GE IS215VCMIH2CA IS200VCMIH2CAA Communication Interface Board

Product core positioning

These two communication interface boards are both part of the GE Mark VIe or related series of industrial control platforms. As the "communication bridge" of the system, their core function is to solve communication compatibility issues between different devices, modules, and control systems. They can achieve bidirectional data exchange between on-site devices (such as sensors and actuators) and control units (such as CPU modules), as well as upper computer systems, transmitting dispersed device data to the control core and accurately issuing control instructions to execution terminals, ensuring the synergy and real-time performance of the entire industrial control process.

Among them, IS200VCMIH2CAA, as an earlier launched model, has been extensively validated in terms of maturity and stability in industrial scenarios; IS215VCMIH2CA has undergone performance upgrades based on it, with advantages in data transmission rate, anti-interference capability, and protocol support range, making it suitable for complex industrial environments with higher requirements for real-time communication and reliability.

Core functional characteristics

1. Multi protocol adaptation capability

Both interface boards support multiple mainstream industrial communication protocols, which is their core advantage in achieving cross device communication. Common supported protocols include Modbus RTU/TCP, Profibus DP, EtherNet/IP, DeviceNet, etc., which can flexibly adapt to different brands and types of industrial equipment. Through the protocol conversion function, a protocol's data source can be converted into a protocol format supported by the control unit or upper computer, breaking the "information island" and achieving system level data interconnection. For example, sensor data using Modbus protocol can be converted to EtherNet/IP protocol and transmitted to the CPU module of GE Mark VIe control system.

2. High speed data transmission and processing

With an upgraded hardware architecture, IS215VCMIH2CA has significantly improved data transmission rates compared to IS200VCMIH2CAA, supporting up to 100Mbps Ethernet transmission rates. It can meet the real-time transmission needs of high-frequency and large capacity data, such as millisecond level collection and feedback of equipment operating parameters in industries such as power generation and metallurgy. At the same time, both interface boards are equipped with high-performance processing chips that can perform preliminary filtering, verification, and caching of transmitted data, reducing the computational pressure on the control core and improving the overall response speed of the system.

3. Strong anti-interference and stability design

In response to the complex electromagnetic environment of industrial sites, both interface boards adopt multiple anti-interference designs. The hardware integrates electromagnetic shielding layer, surge protection circuit, and power filtering module, which can effectively resist interference factors such as industrial high-frequency noise, voltage fluctuations, and lightning strikes, ensuring the accuracy of data transmission. On the software side, it has a data retransmission mechanism and error checking function. When there is a brief communication interruption or data loss, it can automatically initiate a retransmission request to ensure the stability of the communication link. It can maintain stable operation within a wide temperature range of -40 ℃~70 ℃, and is suitable for harsh industrial scenarios such as high and low temperatures.

4. Flexible configuration and diagnostic functions

Support parameter configuration through GE's dedicated configuration software (such as ToolboxST). Engineers can flexibly set communication protocol types, data transmission cycles, address mapping relationships, and other parameters according to actual application needs, making the operation convenient and efficient. At the same time, both interface boards have comprehensive self diagnosis and fault alarm functions, and can provide real-time feedback on power status, communication link status, module operation status, and other information through onboard indicator lights or software interfaces. When there are module failures, communication interruptions, and other issues, it can quickly locate the fault point, reducing operation and maintenance costs and downtime.

Key technical parameters

The following is a comparison of the core technical parameters of two communication interface boards for accurate selection:

parameter category

IS200VCMIH2CAA

IS215VCMIH2CA

communication interface

1 Ethernet port (10/100Mbps adaptive), 2 RS485 interfaces

2 Ethernet ports (10/100Mbps adaptive), 3 RS485 interfaces

Supported Protocols

Modbus RTU/TCP、Profibus-DP、DeviceNet

Modbus RTU/TCP、Profibus-DP、EtherNet/IP、DeviceNet、Profinet

power input

DC 24V ±10%

DC 24V ±10%

Operating Temperature

-40℃~65℃

-40℃~70℃

Data processing delay

≤10ms

≤5ms

Installation method

DIN rail installation/panel installation

DIN rail installation/panel installation

Protection level

IP20 (board level)

IP20 (board level)

Typical application scenarios

Two interface boards, with their high reliability and flexible adaptability, are widely used in industrial fields such as power, metallurgy, chemical, and rail transit. Specific scenarios include:

1. Power industry: In the unit control system of thermal power plants and hydropower stations, temperature, pressure, flow and other sensors on site are connected to the Mark VIe control system to achieve real-time collection of unit operating parameters and issuance of control instructions, ensuring stable power generation of the unit. Due to its higher real-time performance, IS215VCMIH2CA is often used in key control processes such as load regulation of the unit.

2. Metallurgical industry: In the control systems of blast furnaces and converters used in steel production, different brands of frequency converters, PLCs, and detection equipment are adapted to achieve collaborative control of parameters such as temperature, liquid level, and composition during the smelting process, thereby improving smelting efficiency and product quality.

3. Chemical industry: In the control system of reaction vessels and storage tanks in chemical production, anti-interference design is used to resist the complex electromagnetic environment of chemical workshops, ensuring stable transmission of key data such as material ratio and reaction temperature, and guaranteeing the safety and continuity of the production process.

4. Rail Transit Industry: In the traction power supply system of subways and high-speed railways, connecting power supply equipment and control centers to achieve real-time monitoring and fault warning of power supply status, ensuring the safe operation of rail transit.

Precautions for use

1. Installation specifications: During installation, it is necessary to ensure good ventilation, avoid close contact with equipment with high temperature, high humidity, and strong electromagnetic interference, and reserve sufficient heat dissipation space to prevent module performance degradation due to overheating. When installing DIN rails, it is necessary to ensure that they are firmly fixed to avoid vibration affecting the stability of interface connections.

2. Wiring requirements: The power wiring must strictly distinguish between positive and negative poles to avoid module damage caused by reverse connection; Communication lines should use shielded cables, and the shielding layer should be grounded at one end to reduce the impact of electromagnetic interference on data transmission; Lines with different communication protocols should be laid separately to avoid cross interference.

3. Parameter configuration: When configuring parameters, they should be consistent with the communication parameters of upstream and downstream devices (such as baud rate, address, protocol type) to avoid communication failure caused by parameter mismatch. It is recommended to set parameters through GE's official configuration software and save the configuration file for future maintenance.

4. Maintenance: Regularly inspect the appearance of the module and clean the surface dust; Monitor the operating status of the module through diagnostic functions, promptly detect and handle communication abnormalities, power failures, and other issues; When replacing modules, ensure that the model matches to avoid system compatibility issues caused by model mismatch.

5. Firmware upgrade: If you need to upgrade module firmware, you need to obtain the corresponding firmware version of the model through GE's official channels, strictly follow the upgrade process, and avoid module damage caused by sudden power outages during the upgrade process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-