Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

07CR41 Advant Controller Basic Unit - 24VDC 8 24VDC Inputs 6 Relay Outputs

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 13.0 oz (0.8kg )

Tariff Code: 8538907080

Country of Origin: Sweden

Ships from Webster NY, USA

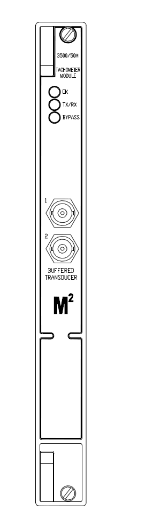

ABB ISBP260520R1001 07CR41 Advant Controller Basic Unit - 24VDC

Basic Information

Product Model Number: ISBP260520R1001 07CR41.

Product name: Advant Controller Basic Unit - 24VDC, this is an Advant Controller Basic Unit from ABB with an operating voltage of 24VDC.

Functional features

Control Functions

Core control capability: as the basic unit of the controller, it is the core part of the whole control system and is responsible for executing the control algorithm and logic. It can precisely control various devices and parameters in industrial processes, such as controlling the speed of motors, the opening of valves, and the adjustment of temperature. The control algorithm can be simple proportional-integral-derivative (PID) control or more complex model-based control strategies to meet the needs of different industrial scenarios.

Multi-tasking capability: With multi-tasking capability, it is capable of handling multiple control tasks at the same time. In a complex industrial automation system, it may be necessary to control multiple devices or monitor multiple parameters at the same time, and this controller basic unit can effectively allocate computing resources to process these tasks in parallel to ensure the efficient operation of the system. For example, in a chemical production process, it can simultaneously control the temperature of the reactor, the stirring speed and the feed rate of the material.

Communication Functions

Multiple communication interface support: It is equipped with multiple communication interfaces, such as Ethernet interface, serial interface (e.g. RS-232, RS-485) and so on. These communication interfaces enable it to exchange data and communicate with other devices. Through the Ethernet interface, it can be connected to the factory's LAN to communicate with the upper computer (e.g., monitoring computer, server), which is convenient for operators to monitor and manage remotely. The serial interface, on the other hand, can be used to connect some traditional devices that only support serial communication, such as some old models of sensors or actuators.

Communication protocol compatibility: It supports a variety of industrial communication protocols, such as Modbus, Profibus and so on. This makes it possible to seamlessly connect with devices produced by different manufacturers that comply with these protocols, enhancing the openness and compatibility of the system. For example, in an automated production line, it can communicate with different brands of motor drives, PLCs (Programmable Logic Controllers) and other devices to achieve collaborative work between devices.

Data Processing and Storage Functions

Data Acquisition and Processing: It is capable of acquiring data from various input devices (e.g., sensors) and processing such data. It can perform filtering, conversion, calculation and other operations on the collected data. For example, the analogue data collected by the temperature sensor is filtered to remove noise interference, and then converted to the actual temperature value for subsequent control and monitoring.

Data storage capability: It has a certain data storage function for storing control programmes, configuration parameters and historical data. The stored control program defines the control logic and algorithms of the controller, while the configuration parameters specify the communication mode with external devices, mapping of input and output signals, etc. Historical data storage can be used for troubleshooting, process analysis, and other purposes. For example, storing the operating parameters of a device over a period of time in the past allows analysis of the cause of failure in the event of a device malfunction.

Reliability and Safety Features

Redundancy design (possible): some models may have redundancy features, such as dual power inputs, dual communication channels, etc. This redundancy design can improve the reliability of the system, in the event of a failure of one power supply or communication channel, the other can continue to work to ensure that the system will not interrupt the operation. For example, in some industrial processes that require high levels of continuous production, such as power production and petroleum refining, the redundancy design can effectively reduce downtime due to equipment failure.

Security mechanisms: Built-in security mechanisms such as access control and password protection. Access control restricts the operating privileges of different users, e.g. only authorised engineers can modify the control program and important configuration parameters, preventing unauthorised personnel from malfunctioning the system. Password protection protects the security of the system against data leakage and malicious attacks.

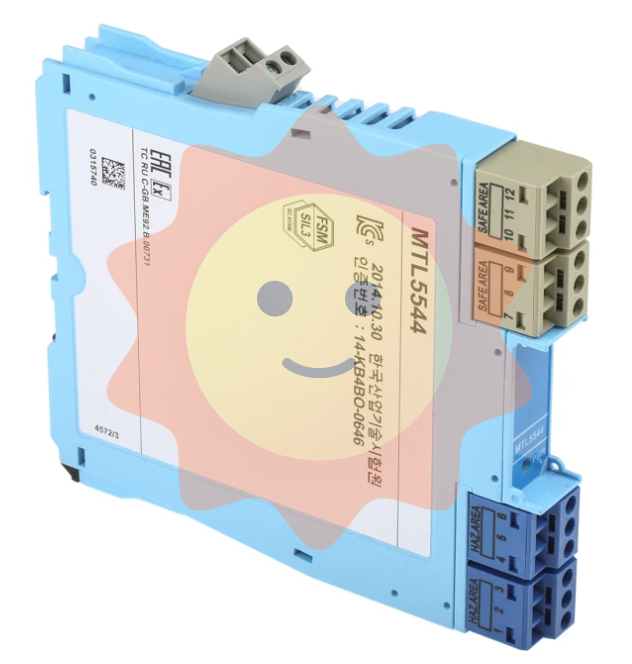

Physical Features and Interfaces

Interface layout and types: A wide range of interfaces are available, including digital inputs, digital outputs, analogue inputs and analogue outputs. Digital input interfaces are used to connect digital sensors (e.g. limit switches, proximity switches) and digital signal sources, and digital output interfaces are used to control digital actuators (e.g. relays, indicator lights). Analogue input interfaces are used to connect analogue sensors (e.g. temperature sensors, pressure sensors) and analogue output interfaces are used to control analogue actuators (e.g. control valves, frequency converters). The interface type may be a pin-type interface or a screw terminal interface, which facilitates the connection of different types of wires.

Physical design: The design is generally compact and easy to install in limited spaces such as control cabinets or equipment racks. The housing is usually made of metal or high-strength engineering plastics, with good impact resistance and heat dissipation performance. In terms of installation, it may support rail mounting or screw-fixed installation, which is convenient for users to choose according to the actual installation environment and requirements. The internal circuit layout is reasonable, taking into account the electromagnetic compatibility and heat dissipation requirements to ensure long-term stable operation.

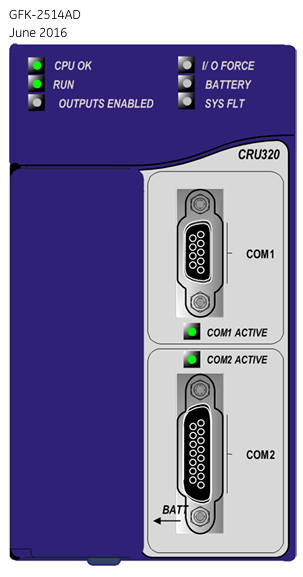

Indicator Lights and Status Display: Equipped with several indicator lights to show the working status of the controller. For example, there is a power indicator to show whether the power supply is normal or not, a communication indicator to show whether the communication is normal or not, and a fault indicator to show whether there is a fault or not. These indicators enable users to quickly judge the operation of the controller in the field.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com