LM80 is a high-performance laser liquid level transmitter suitable for measuring liquid level, distance, and position in extreme environments. It has long range and high precision characteristics and can be widely used in industrial process control scenarios, such as measuring materials in silos and containers, and positioning mobile machinery.

ABB LM80 Laser level transmitter

Product Overview

LM80 is a high-performance laser liquid level transmitter suitable for measuring liquid level, distance, and position in extreme environments. It has long range and high precision characteristics and can be widely used in industrial process control scenarios, such as measuring materials in silos and containers, and positioning mobile machinery.

Measurement range: The maximum liquid level application is 100 meters (328 feet), and the maximum positioning application is 150 meters (492 feet).

Core advantage: No beam divergence (avoiding false echoes), can measure any angle and any surface; Featuring a sturdy aluminum alloy casing and a built-in 1/8-inch NPT purge port, calibration is not required and the setup is intuitive and easy.

Laser configuration: During normal operation, it is a 1M class infrared laser (905nm, peak power 45W, average power 12mW). Within 2 minutes of startup, it activates a 3R class visible aiming laser (635nm, power<2mW). The 1M class device properties can be maintained by setting the aiming laser to be completely turned off.

Safety regulations

1. Laser safety

1M class laser: It is prohibited to directly view through optical instruments such as microscopes and telescopes.

3R class laser (2 minutes after startup): Do not look directly at the beam to avoid exposure to dangerous laser radiation.

Operation restrictions: Only operate according to the instructions specified in the manual. Unauthorized adjustment of controls or performance may result in radiation risks.

2. Electrical safety

Grounding requirements: Equipment and connected power lines must be reliably grounded, and protective grounding must always be effective. Missing grounding may pose a risk of electric shock; Only grounded power sockets can be used, and extension cords must have conductive protection (grounding).

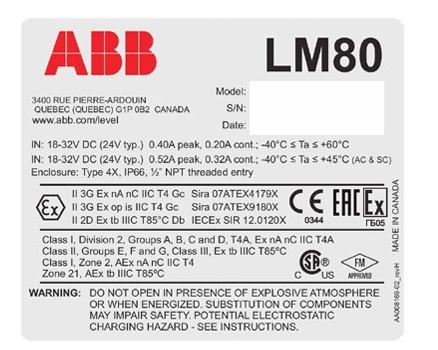

Voltage adaptation: Before use, confirm that the input voltage meets the requirements of 18-32V DC (typical 24V), with a peak current of 0.40A and a continuous current of 0.20A.

3. General safety

Dangerous area: It is prohibited to open equipment or disconnect connections in dangerous areas (such as environments with flammable/combustible gases); Before measuring flammable products, the equipment must be approved by the local inspection agency.

Electrostatic protection: Exposed plastic parts and ungrounded metal parts may accumulate static electricity, and should be avoided from use in dusty environments. When cleaning, wipe with a damp cloth.

Tag retention: It is prohibited to remove warnings and warning labels to ensure that users can access safety information at any time; Do not use when the equipment is damaged, please contact ABB service personnel.

Installation Guide

1. Installation prerequisites

Optical path requirements: The equipment should be of optical line of sight type, and the beam path should be unobstructed; Special parameters can be pre-set in the workshop before installation, and only the measurement target needs to be aimed at on site.

Environmental adaptation: The working temperature range is -40 ℃ to 60 ℃ (-40 ℃ to 45 ℃ when equipped with a heating lens), and it takes 15 minutes to preheat the electronic components after installation to stabilize them.

2. Key steps

Dust prevention and cooling: P801 dust prevention pipes should be installed in dusty environments, and it is recommended to use 3-5psi air blowing for high dust scenarios; P802 cooling pipes can be installed in high-temperature environments to isolate high-temperature process interfaces through convective heat dissipation.

Alignment requirement: There is no need to vertically align the measuring surface (liquid applications are recommended to be as vertical as possible) to ensure clear visibility; Avoid aiming at the sun or narrow rough pipes, and stay away from areas where materials fall.

Grounding and Wiring: Use a 16AWG (1.5mm ²) wire for grounding, and it is recommended to use a No. 10 copper grounding terminal; Shielded cables are required for power and signal, avoiding close laying with high-voltage cables. It is recommended to install power filters and signal isolators in industrial environments with strong electromagnetic interference.

Installation accessories: Supports multiple installation methods, such as 4/6-inch universal mounting plate (compatible with ANSI 150 and DIN PN10 flanges), 3A class flange, adjustable rotating flange (S800), adjustable bracket (A800), etc. For specific dimensions and assembly methods, please refer to the attached figure in the manual.

Configuration and Operation

1. Communication settings

Communication method: Supports communication with the device through LCD2 handheld configuration device (with built-in RS232 cable, easy to operate, only accessing basic settings) or PC/laptop (requiring RS232 to USB cable USBR, accessing all settings through terminal software such as PuTTY).

PuTTY configuration steps:

Download and open PuTTY, select the serial port (such as COM5, need to confirm from Windows Device Manager) in the "Session".

Enter "Connection Serial" and set the baud rate to 19200, data bit to 8, checksum to None, stop bit to 1, and flow control to None.

Click "Open" to complete the configuration, and the device will continue to display the distance and 4-20mA output value after startup.

2. Menu and parameter settings

(1) Main User Menu

Press the spacebar to enter the main menu, which includes 3 submenus. Press the number key to select; After 2 minutes of inactivity, the device will automatically restart for measurement. Press the "S" key to manually restart.

Menu Options Function Description

4-20mA setting configuration includes 4mA/20mA corresponding range, fail safe mode (3.6mA/21mA/hold last value), safe time, and supports 4-20mA output testing and calibration

Relay settings set the opening and closing distance of relay A/B, supporting manual testing of relay status (on/off)

Instrument settings: Select the running program (suitable for different applications), measurement unit (meters/feet), reference point offset (± 1 meter adjustment), display the internal temperature and signal strength of the device

(2) Application selection

The device comes with 5 preset programs that are suitable for different scenarios and can be selected through the instrument settings menu. The default parameter values can be modified by ABB professionals.

Program Type Applicable Scenarios Core Features

Standard (0) demonstration or dust-free environment with unchanged gain, fastest response

Variable gain technology for optimizing signal separation in light/moderate dust environments (such as plastic particle silos) with light dust (1)

Enhanced filtering for medium/heavy dust environments (such as coal bunkers and sawdust bins) to adapt to high dust interference

Positioning (3) Mobile mechanical positioning (such as overhead cranes, stacker reclaimers) is suitable for fast moving targets, with a range of up to 150 meters

Customized (4) Special scenarios (such as crushers, small hoppers) can be configured with parameters by users to meet personalized needs

Maintenance and troubleshooting

1. Maintenance requirements

Daily maintenance: The equipment has no moving parts and does not require regular maintenance; The dust environment requires regular inspection of the lens, blowing the dust with instrument air, and cleaning with alcohol and optical wiping cloth if necessary.

Service restriction: The equipment has no on-site replaceable parts, and all repairs must be carried out by professional personnel from ABB factories; Opening the device will void the warranty.

Scrap disposal: The equipment does not contain components that comply with the EU WEEE directive, but it is recommended to dispose of it through a formal recycling system. In the European region, dealers should be contacted to dispose of scrapped equipment.

2. Troubleshooting

Possible causes and solutions for the fault phenomenon

The device has no response. The power supply is not connected, the voltage is abnormal, the polarity is incorrect, and the grounding is poor. Check the power supply connection, voltage (18-32V DC), polarity, and confirm that the grounding is reliable

4-20mA output error range setting error, PLC/instrument scaling error, electromagnetic interference, wiring fault. Use PC/LCD2 to check the distance reading, verify that the 4/20mA range is consistent with the PLC, rewire or shield the cable, and check the isolator wiring

Serial port reading error, lens contamination, light path obstruction, improper dust environment setting, laser not aimed at target. Clean the lens, remove light path obstacles, switch to the "heavy dust" program, adjust the laser aiming at the target

Unstable device readings, laser misalignment, electromagnetic interference, poor grounding, dust interference. Confirm that the aiming laser is centered, rewire, reinforce grounding, and optimize dust environment settings (such as blowing)

Accessories and Certification

1. Main accessories

Accessory model name, function, and specifications

P801 dustproof pipe made of 304 stainless steel, with a diameter of 140mm and a length of 257.2mm, prevents lens dust accumulation and supports blowing

P802 cooling pipe made of 304 stainless steel, with a diameter of 140mm and a length of 260.4mm, isolated from high temperature interface

P804/P806 mounting plate 4 inches (DN100)/6 inches (DN150), compatible with ANSI/DIN flange, 304 stainless steel

F804/F806/F810/F815 installation flange 4/6 inch raised face flange (ANSI 150), DIN 100/150 flange, 304 stainless steel

LCD2 handheld configuration device on-site setup and testing, displaying distance and 4-20mA value, unable to access advanced menu

USBR RS232 to USB cable for communication between PC and devices, used in non hazardous areas

2. Certification qualifications

The equipment complies with multiple international certification standards to ensure compliant use worldwide, including CE, ATEX, IECEx, CSA, FM certification. Specific certification details can be found in the certificate information in Appendix C (such as CSA certificate number 22065534, FM certification compliant with standards 3600, 3611, etc.)

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-