ABB O3EX HENF315845R2 is a high-performance control module designed specifically for industrial automation scenarios, belonging to ABB's industrial control product system. This module has the core advantages of high reliability, precise control capability, and good compatibility, and can be seamlessly integrated into various industrial control systems, providing key support for the stable operation and efficient regulation of the production process. Its design strictly follows industrial standards and can adapt to complex and harsh industrial environments. It is widely used in multiple fields such as power, metallurgy, chemical industry, and manufacturing, undertaking important control tasks such as signal acquisition, logical operation, and instruction execution.

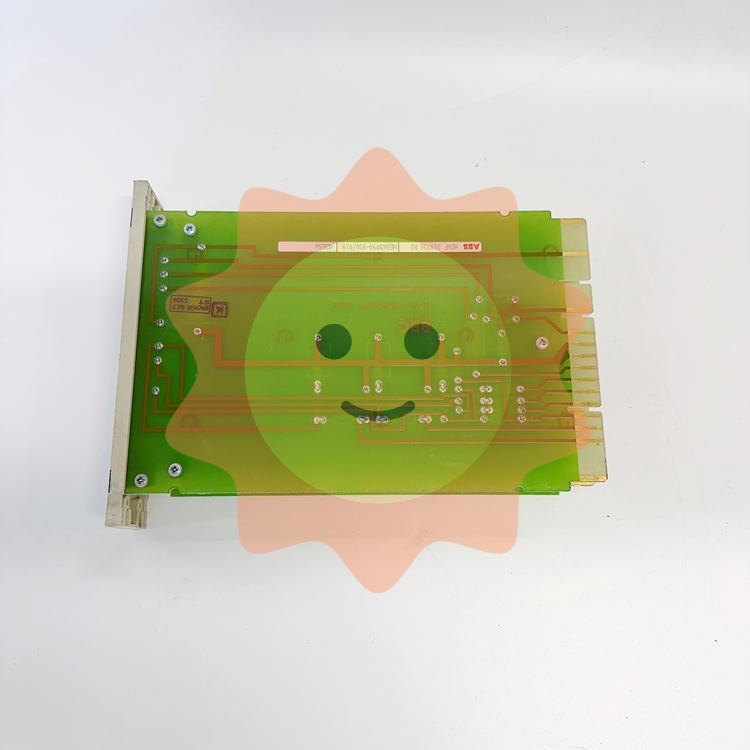

ABB O3EX HENF315845R2 Industrial Control Module

Basic overview of module

ABB O3EX HENF315845R2 is a high-performance control module designed specifically for industrial automation scenarios, belonging to ABB's industrial control product system. This module has the core advantages of high reliability, precise control capability, and good compatibility, and can be seamlessly integrated into various industrial control systems, providing key support for the stable operation and efficient regulation of the production process. Its design strictly follows industrial standards and can adapt to complex and harsh industrial environments. It is widely used in multiple fields such as power, metallurgy, chemical industry, and manufacturing, undertaking important control tasks such as signal acquisition, logical operation, and instruction execution.

Core Features and Advantages

2.1 High reliability and stability

The module adopts industrial grade components and reinforced packaging design, with excellent anti-interference ability, which can effectively resist electromagnetic interference, voltage fluctuations and other interference factors in industrial sites. At the same time, it integrates a comprehensive fault diagnosis and self-protection mechanism internally, which can monitor the operation status of the module in real time. When abnormal situations such as overcurrent, overvoltage, and overheating occur, protective measures can be quickly triggered to reduce the risk of equipment damage and ensure the continuous and stable operation of the control system. The mean time between failures (MTBF) reaches the industrial high-end level.

2.2 Accurate Control Performance

This module is equipped with a high-performance microprocessor, which has fast computing speed and strong processing capability, and can achieve precise acquisition and rapid response to various industrial parameters. Its control accuracy reaches millisecond level, which can meet the control requirements of high-precision production processes. Whether it is adjusting the motor speed, valve opening, or controlling process parameters such as temperature and pressure, it can ensure the stability and accuracy of the control effect, and help improve the quality consistency of production products.

2.3 Good compatibility and scalability

ABB O3EX HENF315845R2 follows common industrial communication protocols and interface standards, and can seamlessly integrate with ABB's PLC, DCS and other control systems, as well as other brands of industrial automation equipment. The module reserves rich expansion interfaces, supporting the addition of input and output channels or expansion function modules according to actual application needs, greatly improving the flexibility of system configuration and adapting to industrial control scenarios of different scales and complexities.

2.4 Convenient Installation and Maintenance

The module adopts a standardized guide rail installation method, with a simple and efficient installation process, which is convenient for on-site construction and layout adjustment. Its external interface adopts anti misconnection design, reducing the risk of wiring errors. At the same time, the module supports online diagnosis and parameter configuration functions. Maintenance personnel can obtain real-time module operation data through dedicated software or control systems, quickly locate and solve faults, effectively shorten maintenance time, and reduce maintenance costs.

Key technical parameters

parameter category

Specific parameters

Instructions

Power Specifications

Input voltage: 24V DC ± 10%

Industrial standard DC power supply, adaptable to voltage fluctuations

input channel

Analog input: 4-8 channels

Supports standard signals such as 0-10V DC and 4-20mA

Digital input: 8-16 channels

NPN/PNP compatible, response time ≤ 1ms

output channel

Analog output: 2-4 channels

Output range 0-10V DC, 4-20mA, accuracy ± 0.1%

Digital output: 4-8 channels

Relay output/transistor output optional, load capacity 1A/24V DC

communication interface

RS485、Ethernet

Supports mainstream industrial communication protocols such as Modbus and Profinet

working environment

Temperature: -20 ℃~60 ℃; Humidity: 5%~95% (no condensation)

Adapt to harsh industrial environments

Overall dimensions

120mm x 80mm x 60mm (length x width x height)

Compact design, saving installation space

Typical application scenarios

4.1 Power industry

In the process of power production and transmission, this module can be used for monitoring substation equipment, auxiliary control of generator sets, and other scenarios. By collecting key parameters such as transformer temperature, bus voltage, and current, transmitting them in real-time to the control system, and adjusting relevant actuators according to instructions, the stable operation of the power system is ensured and the reliability of power supply is improved.

4.2 Chemical Industry

The control requirements for parameters such as temperature, pressure, liquid level, and flow rate are extremely high in the chemical production process. The ABB O3EX HENF315845R2 module can accurately collect these process parameters, output control signals through logical operations, adjust reaction kettle temperature, feed valve opening, etc., to ensure the safety and stability of chemical production processes and avoid production accidents caused by parameter fluctuations.

4.3 Manufacturing Industry

In assembly line operation scenarios such as mechanical manufacturing and automobile production, this module can serve as the core component of the production line control unit, achieving collaborative control of conveying equipment and processing equipment. By receiving instructions from PLC, precise control of equipment start stop, operation speed, etc., while collecting equipment operation status data, provide support for intelligent scheduling and maintenance of production lines, and improve production efficiency.

Installation and usage precautions

-Module installation must strictly follow the guide rail installation specifications to ensure a secure installation and avoid interface looseness or module damage caused by vibration.

-Before wiring, it is necessary to confirm that the power supply voltage is consistent with the rated voltage of the module. Reverse wiring is strictly prohibited to avoid burning out the internal circuit of the module.

-The installation location should be far away from strong electromagnetic radiation sources (such as large motors, frequency converters) and high temperature, high humidity, and corrosive gas environments. If unavoidable, corresponding shielding, heat dissipation, or protective measures should be taken.

-Before the module is put into use for the first time, it needs to be configured with specialized software to ensure that communication protocols, input and output signal types, and other parameters match the control system.

-In daily maintenance, it is necessary to regularly check the module wiring, operating temperature, and indicator light status, and promptly handle any abnormalities to avoid the expansion of faults.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-