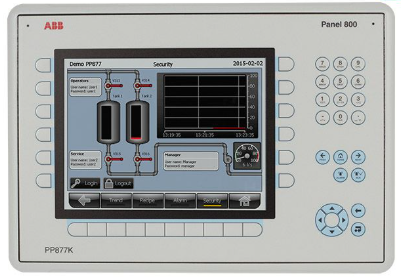

ABB PP877 3BSE069272R2 is a high-performance touch screen designed specifically for the industrial automation field, belonging to the ABB Advant OCS or AC 800M control system supporting human-machine interface (HMI) product series. Its core is used for industrial field equipment operation, parameter monitoring, fault diagnosis, and process control, widely adapted to harsh industrial environments such as power, chemical, metallurgical, water treatment, intelligent manufacturing, etc. It can achieve seamless linkage with ABB PLC and DCS systems, improve on-site operation efficiency and system control accuracy.

ABB PP877 3BSE069272R2 Industrial Touch Screen

Product positioning and applicable scenarios

ABB PP877 3BSE069272R2 is a high-performance touch screen designed specifically for the industrial automation field, belonging to the ABB Advant OCS or AC 800M control system supporting human-machine interface (HMI) product series. Its core is used for industrial field equipment operation, parameter monitoring, fault diagnosis, and process control, widely adapted to harsh industrial environments such as power, chemical, metallurgical, water treatment, intelligent manufacturing, etc. It can achieve seamless linkage with ABB PLC and DCS systems, improve on-site operation efficiency and system control accuracy.

Core hardware parameters

1. Display specifications

-Screen size: 7-inch color TFT LCD display, typically with a resolution of 800 × 480 pixels (some versions support higher resolutions), featuring high brightness (≥ 300 cd/㎡) and high contrast characteristics, ensuring clear visibility in industrial environments such as strong light and dust. The viewing angle range reaches 160 ° (horizontal/vertical), meeting the needs of multi workstation operation.

-Touch mode: Resistive touch screen (some versions can choose capacitive), supports single point precise touch, response time ≤ 200ms, touch life ≥ 1 million times, suitable for industrial glove operation, resistant to slight mechanical impact and scratching.

2. Processor and Storage

-Equipped with an industrial grade embedded processor (such as ARM architecture) with a clock speed of ≥ 800MHz, coupled with ≥ 256MB DDR memory and ≥ 512MB Flash storage (supporting expansion to 1GB), it can smoothly run complex HMI programs, store historical data, operation logs, and custom interface configurations.

3. Interface configuration

-Communication interface: Standard configuration includes 1 Ethernet RJ45 port (supporting 10/100Mbps adaptive, compatible with industrial protocols such as Modbus TCP and Profinet), 1-2 RS485/RS232 serial interfaces (used to connect PLC, frequency converter and other devices, supporting Modbus RTU protocol), and some versions can be optionally equipped with Profibus DP interface to achieve high-speed data exchange with ABB AC 800M and other systems.

-Power interface: Supports 24VDC industrial power input (voltage range 18-30VDC), with overvoltage and overcurrent protection functions, power consumption ≤ 15W, suitable for centralized or independent power supply in industrial sites.

-Expansion interface: Reserved USB 2.0 interface (for program download, data backup, external mouse/keyboard), some models support SD card expansion storage to meet flexible on-site configuration requirements.

4. Environmental adaptability

-Working temperature: -10 ℃ +55 ℃ (wide temperature design, suitable for high and low temperature industrial scenarios), storage temperature: -20 ℃ +60 ℃.

-Protection level: IP65 front panel (dustproof, waterproof), IP20 body, can be directly installed on control cabinet doors or on-site workstations, resistant to dust, moisture, and slight chemical corrosion.

-Anti interference performance: Complies with EN 61000-6-2 (industrial environment anti-interference) standard, has electromagnetic compatibility (EMC) certification, and can operate stably in strong electromagnetic radiation environments (such as near motors and frequency converters).

Core functional features

1. HMI programming and interface customization

-Support specialized programming software such as ABB Control Builder M or Panel Builder, customizable operating interfaces (such as process simulation diagrams, parameter monitoring dashboards, alarm pop ups, operation buttons, etc.), support dynamic graphics, trend curves (real-time/historical data curves), and data report generation, meeting the visual control needs of different industries.

-Support multi language interface switching (Chinese, English, German, etc.), suitable for multinational enterprises or multi language operation scenarios, hierarchical management of operation permissions (such as operator, engineer, administrator permissions), to prevent misoperation.

2. Data monitoring and alarm management

-Real time collection and display of on-site equipment parameters (such as temperature, pressure, flow rate, motor speed, etc.), supporting parameter over limit alarm (sound and light alarm, pop-up prompt), automatic recording of alarm information (including time, type, trigger value), which can be transmitted to the upper computer system through Ethernet for easy fault tracing and analysis.

-Support historical data storage and query (filtered by time range and parameter type), with adjustable data sampling period (1-60 seconds), meeting the needs of process optimization and compliance recording (such as GMP data traceability in the chemical industry).

3. System linkage and control

-Control instructions can be directly sent to the PLC or DCS system (such as starting and stopping equipment, adjusting set values, switching operating modes), with a transmission delay of ≤ 100ms to ensure timely operation response. Combined with hardware interlock function, it prevents illegal operations from causing equipment failures.

-Support remote monitoring and maintenance: By connecting to industrial Ethernet through Ethernet, it is possible to remotely download HMI programs, update firmware, view operation logs, reduce on-site maintenance workload, and improve equipment operation and maintenance efficiency.

4. Reliability and safety design

-Equipped with hardware watchdog function, it automatically restarts when the system is abnormal, avoiding control interruptions caused by system crashes; At the software level, it supports program backup and recovery to prevent configuration loss.

-Compliant with industrial safety standards (such as EN ISO 13849-1 safety level), supports emergency stop (E-Stop) signal access, and can quickly cut off equipment control signals in case of emergency, ensuring the safety of personnel and equipment.

Installation and usage precautions

1. Installation requirements

-Adopting panel embedded installation (the standard opening size should refer to the product manual, usually around 192 × 138mm), with an installation depth of ≤ 50mm, ensuring that the thickness of the cabinet door or console is compatible. After installation, the front panel should be flush with the surface of the cabinet to avoid water accumulation or dust accumulation.

-The installation location should be away from strong heat sources (such as heaters and motors), strong electromagnetic interference sources (such as frequency converters and high-voltage cables), avoid direct sunlight, ensure good ventilation, and prevent equipment overheating.

2. Wiring specifications

-Power wiring should distinguish between positive and negative poles to avoid reverse connection; Shielded wires are required for communication lines (Ethernet, RS485), and the shielding layer should be grounded at one end (grounding resistance ≤ 4 Ω) to reduce signal interference; When wiring, it is necessary to maintain a distance of ≥ 10cm from strong electrical lines (such as 380V power lines) to prevent electromagnetic coupling interference.

3. Daily maintenance

-Regularly clean the front panel (wipe with a dry soft cloth, avoid using corrosive cleaning agents such as alcohol and gasoline) to prevent touch failure; Check if the interface cables are loose, if the power supply voltage is stable, and ensure that the equipment is powered normally.

-Regularly backup HMI programs and historical data (via USB or SD card) to avoid data loss due to device failures; Check the device's heat dissipation every 6-12 months, clean the dust from the body's heat dissipation holes, and prevent overheating and damage.

Certification and Compliance

-Compliant with EU CE certification (Low Voltage Directive 2014/35/EU, Electromagnetic Compatibility Directive 2014/30/EU), US UL certification (UL 61010-1 Industrial Control Equipment Safety Standard), some models have passed ATEX or IECEx certification, and can be used in explosion-proof areas (such as chemical explosion-proof workshops, explosion-proof versions need to be selected), meeting the compliance requirements of major global industrial markets.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-