Positioning: A continuous gas analyzer designed specifically for process monitoring and emission monitoring, supporting multi-component and high-precision measurements, suitable for gas component detection in industrial environments.

Core advantages: modular design (easy to maintain and expand functionality), support for automatic calibration (reduces operational complexity), multi interface compatibility (adapts to different system integration requirements), measurable flammable gases (meets special scenario requirements).

Basic specifications: 19 inch rack mounted housing (3 height units), protection level IP20, housing material galvanized steel plate (outer surface painted), color options light gray (RAL 7035) or basalt gray (RAL 7012), weight 7-15 kg, working environment temperature+5 to+45 ℃ (+5 to+40 ℃ when Uras26 is combined with other modules), storage and transportation temperature -25 to+65 ℃, relative humidity<75% (slight condensation allowed).

ABB EasyLine EL3020 Continuous Gas Analyzer

Product Overview

Positioning: A continuous gas analyzer designed specifically for process monitoring and emission monitoring, supporting multi-component and high-precision measurements, suitable for gas component detection in industrial environments.

Core advantages: modular design (easy to maintain and expand functionality), support for automatic calibration (reduces operational complexity), multi interface compatibility (adapts to different system integration requirements), measurable flammable gases (meets special scenario requirements).

Basic specifications: 19 inch rack mounted housing (3 height units), protection level IP20, housing material galvanized steel plate (outer surface painted), color options light gray (RAL 7035) or basalt gray (RAL 7012), weight 7-15 kg, working environment temperature+5 to+45 ℃ (+5 to+40 ℃ when Uras26 is combined with other modules), storage and transportation temperature -25 to+65 ℃, relative humidity<75% (slight condensation allowed).

Core Measurement Module Details

1. Uras26 infrared photometer

Measurement principle: Based on the non dispersive infrared absorption method in the wavelength range of 2.5-8 μ m, it supports 1 or 2 optical paths, with 1 or 2 receivers per optical path, and can be measured in single or dual gas paths.

Measurement components and range: It can measure infrared active gases such as CO, CO ₂, NO, SO ₂, N ₂ O, CH ₄, etc. The minimum range is 0-100 ppm, and the upper limit of the range can be extended to 0-100 vol. -%. The maximum range ratio is 1:5, and it supports factory customized ranges (to avoid flammable limits).

Performance parameters:

Stability: Linear deviation ≤ 1% span, repeatability ≤ 0.5% span, zero drift ≤ 1% span/week, sensitivity drift ≤ 1% measured value/week.

Response and detection: Output fluctuation (2 σ) ≤ 0.2% span, detection limit (4 σ) ≤ 0.4% span, 90% response time (T ₉₀) 2.5 seconds (when measuring a pool length of 175mm and a flow rate of 60 l/h), preheating time 30 minutes (without constant temperature)/2 hours (with constant temperature).

Environmental impact: There is no significant impact when the flow rate is between 20-100 l/h; For every 10 ℃ temperature change, zero drift ≤ 2% span, sensitivity drift (without constant temperature) ≤ 3% measured value, and with constant temperature (55 ℃) ≤ 2% measured value; Sensitivity drift (with pressure correction) ≤ 0.2% of the measured value for every 1% change in air pressure.

Calibration method: Zero point calibration uses inert gas (such as N ₂) or ambient air without target components, and endpoint calibration uses a built-in calibration pool (optional) or standard gas mixture. It is recommended to verify the calibration pool setting value annually.

Contact material: The gas pipeline is made of aluminum, the window is made of CaF ₂ or BaF ₂, and the joint is made of 1.4305 stainless steel; The pneumatic hose is made of fluororubber (FPM) and the joint is made of polyvinylidene fluoride (PVDF). It can be equipped with 1.4571 stainless steel pipe and 1.4305 stainless steel joint.

2. Magnos206 oxygen analyzer

Measurement principle: Based on oxygen paramagnetism, magnetic mechanical design, fast response speed.

Measurement components and range: Only measure O ₂, with a minimum range of 0-2 Vol. -% and a maximum range of 0-100 Vol. -%. Supports suppression of zero range (minimum span of 2 Vol. -%, default range of 98-100 Vol. -%), and the range can be freely adjusted (to avoid flammable limits).

Performance parameters:

Stability: Based on a 2 Vol. -% span, linear deviation ≤ 0.5% span, repeatability ≤ 1% span (gas exchange time 3 minutes), zero drift ≤ 0.1 Vol. -% O ₂/week, sensitivity drift ≤ 0.1 Vol. -% O ₂/week or 1% measurement value/week (whichever is smaller).

Response and detection: Output fluctuation (2 σ) ≤ 0.5% minimum range span, detection limit (4 σ) ≤ 1% minimum range span, 90% response time ≤ 4 seconds (flow rate 90 l/h, N ₂ switched to air), preheating time<1 hour.

Environmental impact: Zero drift ≤ 0.1 Vol. -% O ₂ at flow rates of 30-90 l/h; When the temperature changes by 10 ℃, the zero drift is ≤ 1% span (used alone)/2% span (combined with Uras26), and the sensitivity drift is ≤ 0.2% of the measured value; For every 1% change in air pressure, the sensitivity drift (without pressure correction) is ≤ 1% of the measured value, and with pressure correction, it is ≤ 0.01% of the measured value or 0.002 Vol. -% O ₂ (whichever is greater).

Calibration method: Zero calibration uses anaerobic process gas or substitute gas, and endpoint calibration uses process gas or dry air with known oxygen concentration; The 0-5 to 0-25 Vol. -% range supports single point calibration, and it is recommended to regularly verify the zero and endpoint. High suppression ranges (≥ 95-100 Vol. -% O ₂) require calibration with the corresponding standard gas for the range.

Contact material: The sample chamber (directly connected) is made of 1.4305 stainless steel, glass, platinum, rhodium, epoxy resin, and the sealing components are FPM and polyetheretherketone (PEEK).

3. Caldos27 Thermal Conductivity Analyzer

Measurement principle: Based on the difference in thermal conductivity of different gases, a micro mechanical silicon sensor is used with a short T ₉ time.

Measurement of Components and Range: Suitable for binary gas mixtures, such as Ar in O ₂, H ₂ in Ar, CH ₄ in N ₂, etc., with a range of 0-100 Vol. -% (some combinations range from 0-10 to 0-50 Vol. -%), supporting customized measurement of other components, and the range can be freely adjusted within the listed range (to avoid flammable limits).

Performance parameters:

Stability: Linear deviation ≤ 2% span, repeatability ≤ 1% span, zero drift ≤ 2% minimum range/week, sensitivity drift ≤ 0.5% minimum range/week.

Response and detection: Output fluctuation (2 σ) ≤ 0.5% minimum range span, detection limit (4 σ) ≤ 1% minimum range span, 90% response time ≤ 2 seconds (flow rate of 60 l/h), preheating time of about 30 minutes.

Environmental impact: When the flow rate changes by ± 10 l/h, the impact is ≤ 0.5% span (automatically compensated when the test gas and sample gas flow rates are consistent); For every 10 ℃ change in temperature, the impact is ≤ 1% of the span; For every 10 hPa change in air pressure, the impact is ≤ 0.25% of the minimum range span (the larger the range, the smaller the impact); The impact increases when the altitude is greater than 2000 meters.

Calibration method: Zero point calibration uses process gas or substitute gas without measuring components, and endpoint calibration uses process gas or standard gas with known concentration; Support single point calibration (using standard gas), it is recommended to verify the zero and endpoint annually (excluding safety related measurements).

Contact material: The sample chamber (directly connected) is made of 1.4305 stainless steel, the sensor is made of gold and silicon nitride oxide, and the seal is made of perfluororubber (FFKM75).

4. Electrochemical oxygen sensor

Measurement principle: Based on electrochemical sensing technology, it can only be used in combination with Uras26 infrared photometer.

Measurement components and range: Only measure O ₂, the range can be adjusted between 0-5 Vol. -% and 0-25 Vol. -%, and is linear within the range of>1 Vol. -% O ₂.

Performance parameters:

Stability: repeatability ≤ 0.5% span, zero point long-term stability (no need to calibrate zero point), sensitivity drift ≤ 1% measurement range/week.

Response and detection: Output fluctuation (2 σ) ≤ 0.2% measurement range, detection limit (4 σ) ≤ 0.4% measurement range, 90% response time ≤ 30 seconds (flow rate 60 l/h).

Environmental impact: When the flow rate is 20-100 l/h, the impact is ≤ 2% of the measurement range; Within the temperature range of+5 to+40 ℃, every 10 ℃ change has an impact of ≤ 0.2 Vol. -% O ₂; Sensitivity drift (without pressure correction) is ≤ 1% of the measured value for every 1% change in air pressure, and ≤ 0.2% of the measured value with pressure correction (connected to Uras26 with pressure sensor).

Calibration method: No zero point calibration is required, and the endpoint calibration uses ambient air with 20.96 vol. -% O ₂.

Contact material: The sensor is made of polystyrene ABS, polytetrafluoroethylene (PTFE), FPM, the housing is made of polyvinyl chloride (PVC) (FPM sealed), and the air port is made of 1.4571 stainless steel.

Auxiliary configuration and functions

1. Built in gas feeding system (optional)

Two versions: the basic version includes a microfilter and a flow sensor module; The complete version includes a microfilter, solenoid valve, pump, coarse filter, capillary tube, and flow sensor module.

Key parameters: The filter has a 99.99% retention rate for particles larger than 0.1 μ m, the maximum feed rate of the pump is 60 l/h (depending on the analyzer type and inlet/outlet pressure), and the flow rate can be adjusted; The power of the solenoid valve is about 3 W, and the power of the pump is about 10 W.

Contact materials: The filter is made of polyamide and borosilicate glass (including PVDF binder), the solenoid valve is made of PVDF and FPM, the pump is made of PVDF, EPDM, 1.4571 stainless steel, and the flow sensor is made of Al ₂ O ∝, silicon, gold, and glass fiber reinforced plastic (GFK).

Usage restrictions: Not suitable for measuring flammable gases and mixtures, operating temperature+5 to+45 ℃, flow rate 30-60 l/h, corrosive components need to be cooled or absorbed in advance.

2. Operation and Display

Display: Backlit graphic display screen (240 × 160 pixels), capable of displaying numerical values (with physical units) and bar charts, supporting up to 5 measurement values to be displayed simultaneously. Flow status is presented in bar charts, and status information is visually displayed through symbols, which can be directly accessed from the measurement value interface.

Operation: 5-key operation (direction key+confirm key), menu driven interface, supports setting rarely used functions through configuration programs.

Limit monitoring: Limit values can be set through configuration programs, and limit signals (alarms) are output through digital ports.

Interface specifications

1. Electrical interface

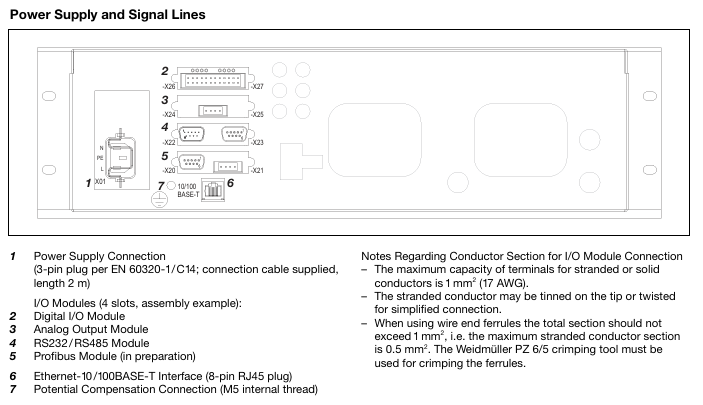

Power supply: 100-240 V AC (-15% to+10%), 50-60 Hz (± 3 Hz), maximum power consumption of 187 W, 3-pin plug (compliant with EN 60320-1/C14), equipped with 2-meter connecting wire.

Analog output module: 2-channel analog output (AO1, AO2), 0/4-20 mA (default 4-20 mA), common negative pole, magnetically isolated from ground, maximum ground potential of 50 V, maximum load resistance of 750 Ω, output not less than 0 mA; 4-pin terminal, supports multi or single wire up to 1 mm ² (17 AWG).

Digital I/O module: 4-channel digital input (DI1-DI4) (optocoupler, built-in 24 VDC power supply, supports floating contacts, 12-24 VDC external voltage or PNP/NPN open collector drive), 4-channel digital output (DO1-DO4) (floating double throw contacts, maximum load 30 VDC/1A); 2 x 12 pin terminals, supporting up to 1 mm ² (17 AWG) wires, with protective components required for inductive/capacitive loads.

Communication module: Modbus module (RS232/RS485 interface), RS232 is a 9-pin Sub-D male connector (RxD, TxD, GND), RS485 is a 9-pin Sub-D female connector (RTxD -, RTxD+, GND); Ethernet 10/100BASE-T interface (8-pin RJ45 plug), used for service and configuration.

Other: Potential compensation interface (M5 internal thread).

2. Gas interface

Interface type: divided into hose connection (4mm inner diameter hose nozzle) and pipe connection (1/8 NPT internal thread, compatible with commercial fittings such as Swagelok) ®), The gas path interfaces of different modules (sample gas inlet, outlet, test gas inlet, etc.) are designed according to functional zoning.

Connection requirements: The connection position of pressure sensors (Uras26 and Caldos27 standard, Magnos206 optional) varies depending on the interface type; The pipeline connection version does not support built-in gas feeding systems, electrochemical oxygen sensors, and dual gas path configurations.

Usage conditions and restrictions

Gas inlet requirements: The dew point of the sample gas must be at least 5 ℃ lower than the gas path temperature (otherwise, a cooler or condenser trap must be installed); The intake pressure is 2-500 hPa (Uras26, electrochemical oxygen sensor) or 2-100 hPa (Magnos206, CaldoS27), with a sampling pump for low pressure and a pressure reducing valve for high pressure; The outlet pressure is atmospheric pressure; Flow range 20-100 l/h (Uras26, electrochemical oxygen sensor), 30-90 l/h (Magnos206), 1-90 l/h (CaldoS27, conventional 10-90 l/h).

Gas compatibility:

Corrosive gases: When containing Cl ₂, HCl, HF, SO ₂, NH ∝, H ₂ S and other components, cooling or absorption treatment should be carried out in advance. Some components need to be consulted with ABB's analysis department. It is recommended to use the AO2000 Magnos106 analyzer when containing NH ∝.

Combustible gases: Only specific versions (stainless steel gas circuit) can be measured, and strict adherence to the operating manual is required; Prohibited for measuring combustible gases/air or gas/oxygen mixtures.

Other: Electrochemical oxygen sensors should avoid background gases containing H ₂ S, chlorine/fluorine compounds, heavy metals, aerosols, thiols, and alkaline components, and the dew point of the sample gas should be ≥ 2 ℃ (not suitable for dry gases).

Installation requirements: When installing multiple devices in a 19 inch rack, at least one height unit spacing should be reserved to ensure air circulation; The equipment vibration must comply with the EN 60068-2-6 standard (0.5g/150 Hz has no effect during operation).

Certification and Compliance

EU certification: Complies with the Low Voltage Directive (73/23/EC) and the Electromagnetic Compatibility Directive (89/336/EC), meets EN 61010-1:2001 (Electrical Safety), EN 61326:1997+A1-A3 (Electromagnetic Compatibility), EN 61000-3-2:2000, and EN 61000-3:3:1995+A1 (Interference Limits) standards.

US Canada Certification: Passed CAN/CSA-C22.2 No. 61010-1-04/UL 61010-1:2004 (2nd edition) certification, suitable for general environments.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-