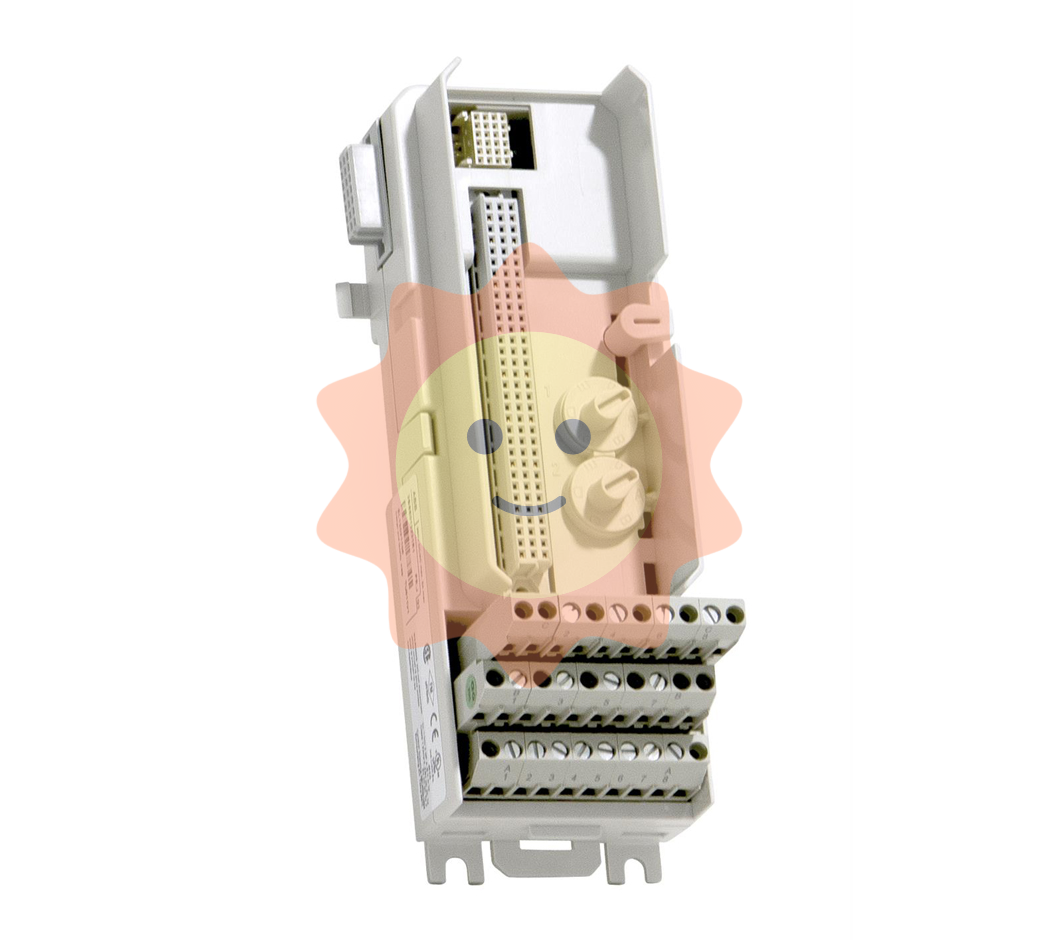

The ABB RMU811 module wiring unit is a high-density modular wiring terminal device specially designed by ABB for industrial automation control systems. It is a supporting component of ABB Advant or AC 800 series control systems. RMU "is an abbreviation for" Relay Module Unit "or" Remote Module Unit ", and" 811 "is a series model identification. Its core function is to serve as a signal relay hub between control modules and field devices, realizing standardized wiring between external devices such as sensors and actuators and PLC and DCS modules. At the same time, it provides wiring protection and status monitoring interfaces, simplifies system wiring, reduces maintenance difficulty, and is widely used in control cabinet integration in automation scenarios such as process industry and manufacturing.

ABB RMU811 Module Termination Unit

Product core positioning

The ABB RMU811 module wiring unit is a high-density modular wiring terminal device specially designed by ABB for industrial automation control systems. It is a supporting component of ABB Advant or AC 800 series control systems. RMU "is an abbreviation for" Relay Module Unit "or" Remote Module Unit ", and" 811 "is a series model identification. Its core function is to serve as a signal relay hub between control modules and field devices, realizing standardized wiring between external devices such as sensors and actuators and PLC and DCS modules. At the same time, it provides wiring protection and status monitoring interfaces, simplifies system wiring, reduces maintenance difficulty, and is widely used in control cabinet integration in automation scenarios such as process industry and manufacturing.

Key technical parameters

1. Wiring and signal parameters

Terminal quantity: 32 independent wiring terminals, divided into 16 sets of differential signal interfaces, supporting compatible access of digital and analog signals.

Signal compatibility: Suitable for DC 24V digital signals (input/output), 4-20mA current signals, 0-10V voltage signals, and can meet the wiring requirements of various types of sensors and actuators.

Rated electrical parameters: Each terminal has a rated voltage of 300V AC/DC, a rated current of 10A, a peak withstand current of 20A (duration of 1s), and complies with IEC 60947-1 standard.

2. System and electrical characteristics

Module interface: Using standard DIN 41612 pin connectors, it can be directly plugged and docked with ABB AC 800M series I/O modules (such as AI810, DO810) without additional wiring.

Protection function: equipped with built-in varistor (MOV) surge protection, capable of withstanding ± 2kV common mode surge; Each terminal is integrated with fuse protection (optional 2A fuse) to prevent overload damage to the module.

Electromagnetic compatibility (EMC): Complies with the IEC 61000-6-2 industrial environment anti-interference standard, has an IP20 protection level, and is suitable for electromagnetic environments with dense wiring inside control cabinets.

3. Physical and environmental parameters

Size: 160mm in length, 80mm in width, and 45mm in height, adopting a compact design that matches the standard I/O module size, making it easy to install densely inside the control cabinet.

Installation method: Supports 35mm DIN rail installation, fixed by snap fasteners, can be installed and disassembled without tools, and can be deployed side by side with ABB I/O modules.

Environmental adaptability: working temperature range -25 ℃~70 ℃, relative humidity 5%~95% (no condensation); Storage temperature -40 ℃~85 ℃, can withstand harsh industrial storage and operating environments.

Core functions and features

Modular quick wiring: "One plug and one connect" is achieved through pin connectors and control modules. The 32 terminal can be pre wired for on-site equipment, and there is no need to rewire when replacing modules, reducing maintenance time from hours to minutes. For example, in a chemical DCS system, when replacing a faulty AI module, only the RMU811 wiring unit needs to be plugged in and unplugged, greatly reducing downtime losses.

Signal classification management: Terminals are designed according to functional zoning (digital input/output, analog input/output), equipped with clear identification and color coding (such as digital blue, analog yellow), which can quickly distinguish signal types and avoid wiring errors. Simultaneously supporting the corresponding labeling of terminal numbers and system point numbers, facilitating later operation and maintenance traceability.

Integrated status monitoring: Reserved terminal voltage detection interface, which can directly measure on-site signals through a multimeter or portable tester without disconnecting the wiring; Some versions are equipped with LED indicator lights, which indicate the on/off status of the terminals (red light indicates that the circuit is connected).

Extended compatibility: Supports multi unit cascading, and can combine 2 RMU811 units into 64 wiring terminals through dedicated connectors to meet the wiring requirements of large I/O module groups; Compatible with third-party I/O modules (such as Siemens S7-400 series), cross brand integration is achieved through adapter adapters.

Typical application scenarios

1. Core application areas

Petrochemical industry

DCS system on-site instrument wiring (temperature/pressure sensors, regulating valves)

Implement standardized wiring between instruments and I/O modules, provide surge protection, and ensure stable signal transmission

Automobile manufacturing

I/O module wiring for welding production line (proximity switch, solenoid valve)

Quickly connect control modules with on-site equipment to shorten production line debugging and maintenance time

Power system

Substation PLC control system wiring (current transformer, circuit breaker status)

Isolate strong and weak electrical signals to prevent misoperation caused by interference and improve system reliability

Food processing

Wiring of production line sensors (liquid level switch, temperature transmitter)

Simplify wiring layout to meet the compact installation requirements of clean workshop control cabinets

2. Example of System Integration

In the inverter control system of a large photovoltaic power station, ABB RMU811 wiring unit serves as the core wiring hub, achieving two major functions: firstly, connecting the signals of 16 photovoltaic string current sensors (4~20mA) through terminals to the AI810 analog input module of AC 800M; The second is to transmit the instructions of the DO810 digital output module to the 16 channel DC circuit breaker through the terminal. When the inverter needs to be expanded, simply adding RMU811 units and corresponding I/O modules can achieve rapid expansion without the need to reconstruct the original wiring system.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-