The ABB SCYC51020 58052582/G pulse trigger board is a core component developed by ABB for industrial power electronic control systems. It is mainly used for precise trigger control of various power semiconductor devices such as thyristors (SCR) and IGBTs. This product, with ABB's profound technical accumulation in the field of power control, has the characteristics of high reliability, high triggering accuracy, and strong anti-interference ability. It is widely suitable for industrial power conversion systems such as frequency converters, rectification devices, reactive power compensation equipment, and intermediate frequency power supplies, providing key trigger signal support for the stable operation of power electronic devices.

As a "bridge" between power devices and control systems, this pulse trigger board can convert the weak electrical control signals output by the control system into strong electrical pulse signals that meet the triggering requirements of power devices, ensuring that the power devices are turned on or off at accurate times, thereby achieving efficient conversion and precise control of electrical energy. It is one of the indispensable core components in industrial automation control systems.

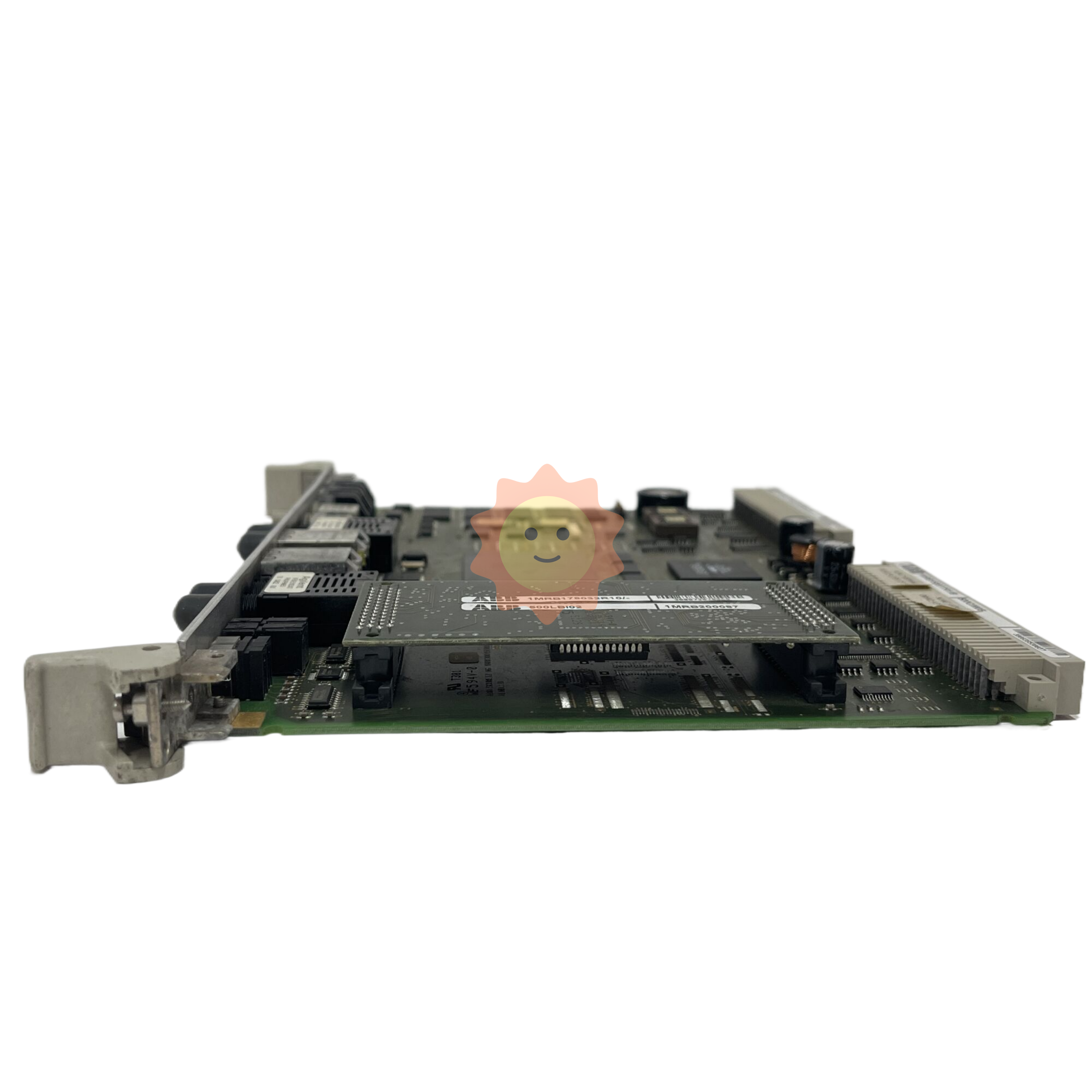

ABB SCYC51020 58052582/G pulse trigger board

Product Overview

The ABB SCYC51020 58052582/G pulse trigger board is a core component developed by ABB for industrial power electronic control systems. It is mainly used for precise trigger control of various power semiconductor devices such as thyristors (SCR) and IGBTs. This product, with ABB's profound technical accumulation in the field of power control, has the characteristics of high reliability, high triggering accuracy, and strong anti-interference ability. It is widely suitable for industrial power conversion systems such as frequency converters, rectification devices, reactive power compensation equipment, and intermediate frequency power supplies, providing key trigger signal support for the stable operation of power electronic devices.

As a "bridge" between power devices and control systems, this pulse trigger board can convert the weak electrical control signals output by the control system into strong electrical pulse signals that meet the triggering requirements of power devices, ensuring that the power devices are turned on or off at accurate times, thereby achieving efficient conversion and precise control of electrical energy. It is one of the indispensable core components in industrial automation control systems.

Core functions and advantages

2.1 Core Functions

-Precise pulse triggering: Supports triggering control of various power devices such as thyristors and IGBTs, with pulse triggering timing accuracy up to microseconds. The triggering angle can be flexibly adjusted according to system requirements to meet the energy conversion needs under different working conditions, such as rectification, inversion, chopping, etc.

-Signal isolation and conversion: Equipped with a high-performance optoelectronic isolation module, it achieves electrical isolation between control signals and power signals, effectively avoiding interference from high voltage and high current in the power circuit to the control circuit. At the same time, it completes the conversion from weak electrical signals to strong electrical pulse signals, ensuring the safe and stable operation of the system.

-Fault detection and protection: It has the function of detecting fault signals such as overcurrent, overvoltage, and undervoltage. When abnormal working conditions are detected, it can quickly cut off the trigger pulse or output a fault alarm signal, timely protect power devices and the entire power electronic system, and reduce the risk of equipment damage.

-Flexible signal adaptation: Supports multiple input control signal types, such as analog (4-20mA, 0-5V) and digital (TTL level), and can seamlessly integrate with various control systems such as PLC, DCS, and dedicated controllers, with strong adaptability.

-Stable operating performance: Equipped with a comprehensive power regulator circuit and anti-interference circuit, it can maintain stable triggering performance in complex industrial electromagnetic environments, adapt to a wide range of power grid voltage fluctuations and environmental temperature changes.

2.2 Product advantages

-High reliability: Adopting ABB industrial grade component selection standards and undergoing rigorous environmental adaptability testing (high and low temperature, humidity, vibration, impact, etc.), the average time between failures (MTBF) is long, which can meet the continuous and stable operation needs of industrial sites.

-Modular design: Adopting a standardized modular structure, it is easy to install, convenient for later maintenance, replacement, and upgrading, and reduces equipment operation and maintenance costs.

-High technological maturity: Based on ABB's years of technical accumulation in the field of power electronic control, the product has been verified through a large number of practical engineering cases, with stable and reliable performance and wide adaptability.

-Comprehensive after-sales support: Relying on ABB's global service network, we can provide users with professional technical consultation, installation and commissioning guidance, and fault repair services to ensure the stable operation of equipment throughout its entire life cycle.

Key technical parameters

parameter category

Specific parameters

Instructions

Model identification

SCYC51020 58052582/G

ABB official model, 58052582/G is the product batch or configuration identification

Input control signal

Analog quantity: 4-20mA/0-5V; Digital quantity: TTL (5V)

Supports two types of signals, which can be selected through dip switches or jumpers

Trigger pulse parameters

Pulse width: 10-100 μ s (adjustable); Pulse amplitude: ≥ 15V; Pulse current: ≥ 1A

Meet the triggering requirements of mainstream power devices, and the pulse parameters can be adjusted according to the device model

Trigger accuracy

Trigger angle accuracy: ± 0.1 °; Pulse synchronization accuracy: ± 1 μ s

Ensure precise on/off timing of power devices to improve energy conversion efficiency

working power supply

DC: 24V ± 10%; Power consumption: ≤ 5W

Wide voltage range adaptation, low-power design, reducing system energy consumption

Environmental adaptation range

Working temperature: -20 ℃~+65 ℃; Relative humidity: 10%~90% (no condensation); Storage temperature: -40 ℃~+85 ℃

Adapt to harsh industrial environments and work stably in high temperature, high humidity and other scenarios

isolation level

Control circuit and power circuit: ≥ 2500Vrms (1 minute)

High isolation level, effectively ensuring the safety of personnel and equipment

Installation method

DIN rail installation or screw fixation

Compliant with industrial standardized installation requirements, easy to integrate into control cabinets

Applicable scenarios

This pulse trigger board is widely used in the following industrial fields due to its excellent performance:

1. Power electronic conversion equipment: such as thyristor rectifier devices, IGBT frequency converters, intermediate frequency induction heating power supplies, high-frequency switching power supplies, etc., responsible for precise triggering control of power devices, improving the efficiency and stability of equipment's power conversion.

2. Industrial motor control: In AC motor speed control systems and DC motor speed control systems, precise control of motor operation status is achieved by cooperating with controllers, reducing motor energy consumption and improving control accuracy.

3. Power system equipment: such as reactive power compensation devices (SVC, SVG), active power filters (APF), etc., used to improve the quality of power grid, stabilize grid voltage, and suppress harmonic interference.

4. Metallurgy and Chemical Industry: In the electric control systems of electric arc furnaces and rolling mills in the metallurgical industry, as well as in the temperature control systems of electrolytic cells and reaction vessels in the chemical industry, stable power device triggering support is provided to ensure the continuity of production processes.

5. In the field of rail transit: In the traction converters and auxiliary power systems of subways, light rails, and other rail transit systems, they adapt to high vibration and wide temperature range working environments to ensure the stable operation of the traction system.

Installation and usage precautions

5.1 Installation precautions

-Before installation, it is necessary to confirm that the product model is consistent with the system requirements, check the appearance of the product for any damage, and ensure that the pins are not bent or deformed.

-Strictly follow the pin definitions in the product manual for wiring, avoid reversing the control signal and power signal, and prevent burning the circuit board.

-The installation location should be far away from high-power heating devices (such as resistors and transformers), ensuring good ventilation and avoiding high temperature accumulation that affects product performance.

-When fixing, it is necessary to ensure that the installation is firm to prevent loose wiring or damage to the circuit board due to vibration during equipment operation.

5.2 Precautions for use

-Before the first power on, it is necessary to check whether the working power supply voltage is within the rated range to avoid overvoltage damage to the power circuit.

-After the wiring is completed, insulation testing is required to ensure good insulation performance between the control circuit and the power circuit.

-According to the model of the power device being driven, adjust parameters such as pulse width and amplitude through the adjustment knob or software settings on the product to ensure reliable triggering.

-If any abnormalities are found during operation (such as abnormal flashing of indicator lights or equipment malfunction), the power should be immediately cut off for inspection, and the fault should be eliminated before restarting to avoid the fault from expanding.

-Regularly maintain the product, clean the dust and debris on the surface of the circuit board, check if the wiring terminals are loose, and ensure long-term stable operation of the equipment.

Common faults and troubleshooting methods

Common Faults

Possible reasons

troubleshooting method

No trigger pulse output

1. The working power supply is not connected; 2. Abnormal input control signal; 3. Pulse generation circuit failure; 4. Open circuit output circuit

1. Check the power wiring and confirm that the power voltage is normal; 2. Use a multimeter or oscilloscope to detect the input control signal; 3. Check the pulse generating chip and peripheral components; 4. Check if the output wiring is loose or broken

Unstable trigger pulse

1. Input control signal fluctuation; 2. Unstable power supply voltage; 3. The circuit board is damp or has electromagnetic interference; 4. Improper setting of adjustment parameters

1. Check the input signal source to ensure signal stability; 2. Check the power regulator circuit and replace the power supply if necessary; 3. Dry the circuit board to enhance electromagnetic shielding; 4. Adjust the pulse parameters again to ensure compliance with requirements

Fault alarm signal output

1. Power circuit overcurrent and overvoltage; 2. Fault detection circuit misoperation; 3. Isolation module malfunction

1. Check the voltage and current of the power circuit and eliminate faults; 2. Check the sensors and peripheral circuits of the fault detection circuit; 3. Test the insulation performance and signal transmission performance of the isolation module

The circuit board is overheating severely

1. The power supply voltage is too high; 2. Short circuit in the output circuit; 3. Aging or damage of electronic components; 4. Poor ventilation and heat dissipation

1. Check the power supply voltage to ensure it is within the rated range; 2. Check the output circuit and eliminate short circuit faults; 3. Check the heating components and replace damaged parts; 4. Improve installation environment, strengthen ventilation and heat dissipation

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-