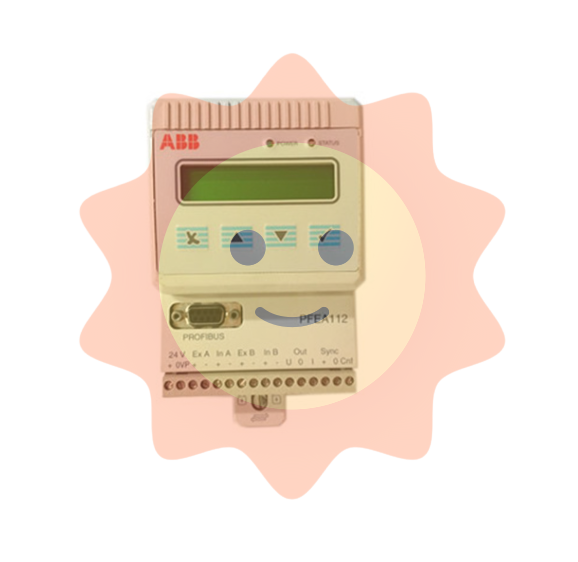

The ABB SYN5200a-Z V217 SYNC HROTACT5 3BHB006713R0217 dual channel synchronization device is a high-precision synchronization control equipment developed by ABB specifically for the power system and industrial drive fields. It is based on the mature technology of the SYNC HROTACT5 series and adopts a dual channel redundancy design. Its core function is to achieve precise synchronization and grid connection between the generator and the grid, grid and grid, and multiple units, ensuring complete matching of voltage, frequency, and phase during parallel operation, and avoiding damage to equipment and systems caused by surge currents. This device integrates high-speed signal processing, intelligent judgment algorithms, and multiple safety protection mechanisms, and is widely used in scenarios such as thermal power plants, hydropower stations, new energy power plants, and industrial self owned power plants. It is a key control equipment to ensure stable grid connection of the power system and improve power supply reliability.

ABB SYN5200a-Z,V217 SYNCHROTACT5 3BHB006713R0217 Dual channel synchronization device

Product Overview

The ABB SYN5200a-Z V217 SYNC HROTACT5 3BHB006713R0217 dual channel synchronization device is a high-precision synchronization control equipment developed by ABB specifically for the power system and industrial drive fields. It is based on the mature technology of the SYNC HROTACT5 series and adopts a dual channel redundancy design. Its core function is to achieve precise synchronization and grid connection between the generator and the grid, grid and grid, and multiple units, ensuring complete matching of voltage, frequency, and phase during parallel operation, and avoiding damage to equipment and systems caused by surge currents. This device integrates high-speed signal processing, intelligent judgment algorithms, and multiple safety protection mechanisms, and is widely used in scenarios such as thermal power plants, hydropower stations, new energy power plants, and industrial self owned power plants. It is a key control equipment to ensure stable grid connection of the power system and improve power supply reliability.

Core Basic Parameters

Product Model

SYN5200a-Z V217、SYNCHROTACT5、3BHB006713R0217

manufacturer

ABB Group

Core processor

32-bit dual core industrial grade processor with a clock speed of ≥ 300MHz

Synchronization channel configuration

Dual independent channels, supporting redundant switching (automatic/manual)

Applicable voltage level

10kV -1000kV (supporting secondary signal input of voltage transformer)

Input signal type

Three phase voltage (AC 100V/220V), frequency signal (50/60Hz), speed signal (0-10V/4-20mA)

Voltage measurement accuracy

± 0.1% (within the rated input range)

Frequency measurement accuracy

±0.001Hz

Phase measurement accuracy

±0.1°

Synchronous response time

≤ 10ms (when synchronization conditions are met)

Synchronization allowable deviation

Voltage deviation ≤± 5%, frequency deviation ≤± 0.1Hz, phase deviation ≤± 1 ° (customizable)

communication interface

RS485(Modbus-RTU)、Ethernet(PROFINET/IEC 61850)、CANopen

power supply voltage

DC 24V/48V ± 15% or AC 110V/220V ± 10%

Working temperature range

-25 ℃~70 ℃ (industrial wide temperature design)

Protection level

IP54 (panel mounted), IP20 (cabinet mounted)

Installation method

19 inch standard cabinet installation, panel embedded installation

Core functional characteristics

1. Dual channel redundancy ensures high reliability

Adopting a dual independent synchronous channel design, the hardware of the two channels is completely isolated and can be configured as "primary backup redundancy" or "parallel operation" mode. In the main backup mode, when the main channel fails (such as sensor abnormalities or circuit failures), the system can automatically switch to the backup channel within 5ms without disturbance, ensuring uninterrupted synchronization control; In parallel mode, two channels simultaneously collect data and cross validate, improving measurement accuracy and judgment reliability, meeting the strict requirements of "no single point of failure" in the power system.

2. Multi scene precise synchronous control

Support multiple synchronous application scenarios: generator grid connection (isolated grid power generation access system), grid to grid interconnection (synchronization of regional grid connection lines), and parallel operation of multiple generators (parallel operation of power station units). The built-in ABB patented "adaptive slip control algorithm" can predict the synchronization point in advance based on the trend of generator speed and grid frequency changes, accurately output closing instructions, ensure that the instantaneous surge current of parallel connection is ≤ 5% of the rated current, far below the national standard requirement of 10%, and effectively protect equipment such as generators, transformers, and circuit breakers.

3. Comprehensive signal acquisition and intelligent judgment

Equipped with rich signal acquisition interfaces, it can simultaneously access three-phase voltage, current, speed, and circuit breaker status signals from both the generator side and the system side. Through technologies such as optoelectronic isolation and signal filtering, it effectively eliminates electromagnetic interference from industrial sites. The system is equipped with multi-dimensional synchronous judgment logic, which not only meets the basic conditions of "equal voltage, equal frequency, and equal phase", but also can be comprehensively judged by combining parameters such as power factor and load changes to avoid false closing caused by instantaneous disturbances.

4. Comprehensive safety protection and fault diagnosis

Integrated multiple safety protection functions: synchronous abnormal protection (such as locking and closing when voltage/frequency deviation exceeds the standard), overvoltage/overcurrent protection, channel fault protection, power supply abnormal protection, and misoperation protection (such as prohibiting closing with load). Equipped with comprehensive self diagnostic functions, it can monitor channel circuits, sensors, communication modules, and power status in real time, accurately locate fault types through fault codes, and trigger linkage actions such as sound and light alarms and passive contact outputs. At the same time, it can store fault records (supporting more than 1000 records) for easy operation and maintenance traceability.

5. Flexible communication and system integration

Supports mainstream power communication protocols such as IEC 61850, PROFINET, Modbus, etc., and can seamlessly integrate into power plant DCS systems, SCADA systems, and smart grid platforms to achieve remote monitoring of synchronous parameters, instruction issuance, and data exchange. Provide standardized API interfaces to facilitate linkage with third-party excitation systems and speed control systems, achieve "synchronous excitation speed control" collaborative control, and optimize grid connection processes. Local support for USB interface enables quick export of historical data and fault reports.

6. Convenient operation and maintenance management

Equipped with a 7-inch color touch screen, supporting Chinese/English interface switching, it can intuitively display real-time parameters such as voltage, frequency, phase difference, and slip between the generator and the system side, and present the synchronization process through dynamic phase diagrams, trend curves, and other forms. Supporting dual control of local buttons and remote communication, operators can complete synchronization mode settings, parameter calibration, threshold adjustment and other operations through the touch screen without the need for professional tools. The system has a built-in parameter backup function, which supports one click factory reset and simplifies the operation and maintenance process.

Applicable scenarios

-Thermal power station: synchronous grid connection control of steam turbine generator, gas turbine generator and power grid to ensure smooth integration of units into the system

-Hydroelectric power station: grid connected hydro generators and parallel operation of multiple units to adapt to the speed fluctuation characteristics of hydro turbines and improve synchronization accuracy

-New energy power station: synchronous control of wind and photovoltaic supporting energy storage power stations to achieve stable integration of renewable energy into the power grid

-Industrial self owned power plants: Interconnection between self owned generators of steel, chemical and other enterprises and the public power grid to ensure coordination between enterprise electricity consumption and the power grid

-Power grid scheduling: synchronization of regional power grid interconnection lines and parallel connection of substation busbars to enhance the reliability of power grid interconnection

-Emergency power supply: Diesel generators and mobile power stations switch synchronously with the load system during emergency power supply to ensure uninterrupted power supply

Precautions for use

1. Before installation, it is necessary to confirm that the device model matches the synchronous scenario and voltage level. The signal input terminals (generator side/system side) should be strictly distinguished according to the product manual to avoid equipment damage caused by reverse connection. Strong and weak current circuits should be wired separately and shielded properly.

2. The installation location should be in a ventilated and dry control cabinet, away from strong electromagnetic interference sources such as high-power inverters and transformers. The ambient temperature should be controlled within the range of -25 ℃ to 70 ℃, avoiding direct sunlight or close to high-temperature heat sources.

Before the first operation, parameter initialization configuration must be completed, including rated voltage, rated frequency, allowable synchronization deviation, channel working mode, etc. The correctness of the synchronization logic must be verified through analog signal testing, and direct connection to real high-voltage signals for debugging is prohibited.

4. During operation, it is necessary to regularly check the operating status of the device, view channel parameters and fault records through the touch screen, calibrate voltage/frequency measurement accuracy regularly (recommended every six months), and ensure the accuracy of synchronous judgment.

When the device issues a fault alarm, synchronous operation should be immediately paused, and the cause should be investigated through fault codes (such as signal disconnection, sensor failure). After troubleshooting, a channel switching test should be conducted to confirm that the dual channel function is normal before resuming use.

When upgrading software or firmware, it is necessary to first backup the current parameter configuration, ensure stable power supply during the upgrade process, prohibit power interruption, and re verify the synchronization function after the upgrade is completed to avoid synchronization failure caused by program abnormalities.

7. Fault repair should be carried out by professionals with qualifications for debugging power automation equipment. Before repair, the power supply and input signals of the device must be cut off. Non professionals are prohibited from disassembling or modifying internal parameters without authorization.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-