ABB XVC770AE 3BHE006414R0001 is a high-end multifunctional module for fieldbus control systems (FCS), belonging to ABB Advant OCS or 800xA distributed control system architecture. As a key "bridge" between on-site equipment and central controllers, this module integrates multiple functions such as signal acquisition, protocol conversion, data preprocessing, and on-site control, and is widely used in distributed control scenarios in industrial fields such as petrochemicals, metallurgy and steel, energy and power, and water treatment. Its flexible functional configuration and stable communication performance provide core support for the efficient operation and precise control of fieldbus systems.

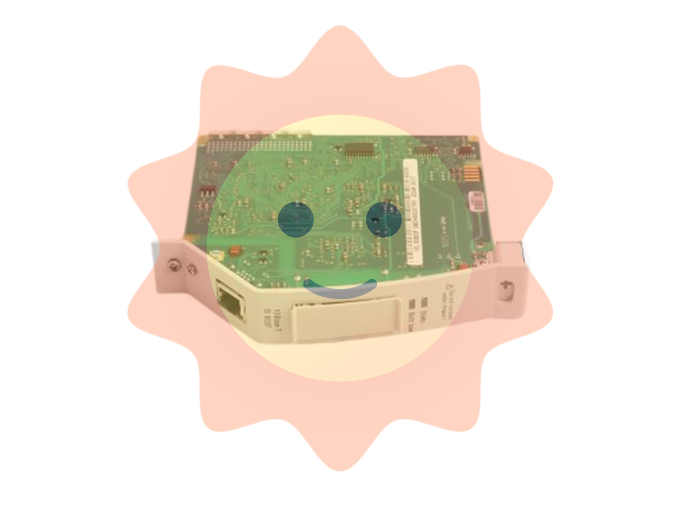

ABB XVC770AE 3BHE006414R0001 fieldbus control system multifunctional module

ABB XVC770AE 3BHE006414R0001 is a high-end multifunctional module for fieldbus control systems (FCS), belonging to ABB Advant OCS or 800xA distributed control system architecture. As a key "bridge" between on-site equipment and central controllers, this module integrates multiple functions such as signal acquisition, protocol conversion, data preprocessing, and on-site control, and is widely used in distributed control scenarios in industrial fields such as petrochemicals, metallurgy and steel, energy and power, and water treatment. Its flexible functional configuration and stable communication performance provide core support for the efficient operation and precise control of fieldbus systems.

Core Features and Advantages

1. Multi functional integrated design

This module breaks the limitations of traditional single function modules and achieves integrated design of analog input/output, digital input/output, pulse signal processing, and HART protocol communication. Users can flexibly configure the function types of each channel through software configuration according to the field needs, and can adapt to the access requirements of different sensors and actuators without changing hardware, greatly simplifying the system hardware architecture, reducing equipment procurement and installation costs, and reducing the wiring complexity in the control cabinet.

2. Efficient and stable bus communication capability

As the core node of the fieldbus system, the XVC770AE module supports various mainstream fieldbus protocols such as PROFIBUS DP/PA, FF (Foundation fieldbus), Modbus RTU/TCP, etc., and has high-speed data transmission capabilities. The bus communication speed can reach up to 12Mbps. The module has a built-in communication fault tolerance mechanism that can automatically detect bus communication abnormalities and perform reconnection. It also supports optoelectronic isolation of bus signals, effectively resisting electromagnetic interference in industrial sites and ensuring real-time and reliable data transmission between field devices and central controllers.

3. Accurate signal processing and control capabilities

The module is equipped with high-precision signal conditioning circuit and 16 bit A/D conversion chip, with an acquisition accuracy of ± 0.1% FS for analog signals. It can accurately capture subtle changes in process parameters such as temperature, pressure, and flow rate on site. At the same time, the module supports local logic control function and can preset simple control logic (such as interlock protection, threshold alarm). In the event of communication interruption between the central controller and on-site equipment, it can still independently complete basic control tasks, avoiding the risk of loss of control in the production process and improving the system's fault tolerance.

4. Powerful diagnostic and maintenance functions

The module is equipped with comprehensive self diagnosis and device diagnosis functions, which can monitor its own operating status in real time (such as power supply voltage, module temperature, channel faults) and the working status of the connected on-site equipment (such as sensor disconnection, actuator jamming). Diagnostic information is uploaded in real-time to the central control system through the bus, and the module panel is equipped with LED indicator lights to visually display the operating status of each channel and bus, making it easy for operation and maintenance personnel to quickly locate the fault point, shorten the fault handling time, and reduce equipment maintenance costs.

5. Excellent environmental adaptability and reliability

The industrial grade enhanced design is adopted, and the module uses components with wide temperature range and anti-aging, which can operate stably in the temperature range of -25 ℃~70 ℃ and humidity environment of 10%~95% (no condensation). The module housing has dust-proof and oil proof performance, with a protection level of IP20. When installed with a control cabinet, it can adapt to harsh on-site environments such as petrochemical workshops and metallurgical plants with high dust and strong interference. The average time between failures (MTBF) exceeds 100000 hours.

Key technical parameters

Basic Information

model

XVC770AE 3BHE006414R0001

Basic Information

affiliated system

ABB Advant OCS/800xA distributed control system

Function Configuration

channel type

8 configurable channels (AI/AO/DI/DO optional)+2 pulse input channels

Function Configuration

Protocol support

PROFIBUS DP/PA、FF、Modbus RTU/TCP、HART

Signal acquisition accuracy

Analog input

± 0.1% FS (16 bit resolution)

Signal acquisition accuracy

Analog output

± 0.2% FS (16 bit resolution)

Signal acquisition accuracy

Digital input/output

Support dry/wet contacts, response time ≤ 1ms

Communication performance

Bus communication speed

Up to 12Mbps, supporting adaptive rate adjustment

Communication performance

communication interface

1 bus interface (with optoelectronic isolation), 1 debugging interface

Power requirements

input voltage

24V DC (± 10%), supports reverse polarity protection

Power requirements

Maximum Power Consumption

≤ 12W (full channel operation)

environmental parameters

Operating Temperature

-25℃~70℃

environmental parameters

relative humidity

10%~95% (no condensation)

environmental parameters

Protection level

IP20 (module body)

reliability index

Mean Time Between Failures (MTBF)

≥ 100000 hours

Typical application scenarios

1. Petrochemical industry

In the production processes of petroleum refining, chemical synthesis, etc., the XVC770AE module can serve as a fieldbus node to centrally connect temperature, pressure, liquid level, flow sensors, and control valve actuator signals of equipment such as reactors, towers, and heat exchangers. By communicating with on-site intelligent devices through the PROFIBUS PA protocol, precise parameter collection and reliable issuance of control instructions are achieved. At the same time, local logic control functions are used to implement emergency stop interlock protection, ensuring the safety and stability of the production process. Its anti-interference performance can effectively cope with the strong electromagnetic environment and corrosive gas effects in chemical workshops.

2. Metallurgical and steel industry

In production processes such as blast furnace ironmaking, converter steelmaking, hot rolling and cold rolling, modules can be connected to equipment signals such as high-temperature sensors, pressure transmitters, hydraulic actuators, etc., and achieve high-speed data exchange with the central control system through the FF bus. In response to the characteristics of high dust and high vibration in metallurgical sites, the module maintains stable operation with a strong structural design. At the same time, through precise signal acquisition and real-time control, it helps to achieve fine adjustment of smelting parameters, improve steel quality and production efficiency, and reduce energy consumption.

3. Energy and power industry

In the auxiliary systems of boilers, turbines, and generators in thermal power plants, as well as in the control of water turbine units in hydropower plants, modules can centrally collect operational status signals and process parameters of equipment such as feed pumps, fans, and valves, and upload them to the DCS system through Modbus TCP/IP protocol. Its local control function can realize the start stop interlock and fault protection of the equipment, ensuring the normal operation of auxiliary equipment in case of system communication interruption, and providing support for the stable power generation of the generator set. At the same time, the high reliability of the module meets the strict requirements of the power industry for continuous operation of equipment.

4. Water treatment industry

In the dosing system, sedimentation tank, and filter control of water plants, as well as the aeration system and sludge treatment system of sewage treatment plants, modules can flexibly configure channel functions and connect signals from pH sensors, turbidity meters, level gauges, metering pumps, and other equipment. Through bus communication, collaborative control of each processing unit is achieved, with precise adjustment of parameters such as dosage and aeration rate to ensure that the effluent quality meets the standard. Its comprehensive diagnostic function can promptly detect sensor faults and equipment abnormalities, ensuring the continuous and stable water treatment process and reducing operation and maintenance costs.

Installation and usage precautions

-The module should be installed in a well ventilated control cabinet away from heat sources and strong electromagnetic interference sources. During installation, a dedicated guide rail should be used to secure it firmly and avoid loose wiring caused by vibration. A spacing of ≥ 5cm should be reserved between modules to ensure effective heat dissipation.

-Before wiring, it is necessary to confirm that the power supply voltage is consistent with the module requirements. Strictly distinguish the power supply terminal, signal terminal, and bus interface according to the wiring diagram to avoid reverse polarity or short circuit between the signal and power supply. On site signal lines should use shielded cables, with the shielding layer grounded at one end to reduce interference.

-Module configuration requires the use of ABB's official configuration software (such as Control Builder M) to configure channel functions, communication protocols, and local control logic based on the type of on-site equipment and control requirements. After the configuration is completed, offline verification is required to ensure that the parameter settings are correct.

-Before the module is put into operation, bus communication testing and signal calibration are required to check the accuracy of signal acquisition and control instruction output for each channel. During operation, regularly check module diagnostic information through configuration software and promptly handle fault alarms.

-During maintenance, it is necessary to first cut off the power supply of the module to avoid plugging and unplugging the wiring terminals when they are live. When cleaning the module, use a dry brush or compressed air to remove dust. Do not use wet cloths or corrosive cleaning agents to prevent module damage.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-