Alternative analysis of coal chemical products

Taking the 600,000-ton/year coal-to-olefin project as an example, its total investment is about 15 billion yuan (excluding olefin deep processing equipment), and the unit product investment is about 25,000 yuan/ton of olefin. According to the current coal resource pit price situation, when the international crude oil price is higher than 60 US dollars/barrel, the coal-to-olefin project has a certain cost competitiveness. And with the rise of international crude oil prices, cost competitiveness continues to increase.

2. Coal-to-natural gas: Energy conversion efficiency is high, which is greatly affected by the price of syngas

Natural gas is a mixture of hydrocarbon and non-hydrocarbon gases naturally contained in the formation. It is mainly used as fuel to make carbon black, chemicals and liquefied petroleum gas. Propane and butane produced from natural gas are important raw materials for modern industry.

Coal-to-natural gas refers to the gasification of coal to produce syngas, and then methanation to produce alternative natural gas (SNG). Coal-derived natural gas has the same properties as conventional natural gas and can be used as an alternative product in various fields. The energy conversion efficiency of coal to natural gas is high, and the technology has been basically mature, and it is an effective way to produce oil substitute products. Coal-to-natural gas project investment is large, need to have a large economic scale, the current single series scale of 1.3 billion to 1.6 billion m3 / year, domestic projects under construction more use 3 series, a total scale of 4 billion m3 / year.

The process flow of coal-to-natural gas is as follows: raw coal reacts with high-purity oxygen and medium-pressure steam from the air separation unit in the coal gasification unit to produce crude gas, which is desulfurized and decarbonized by washing with low temperature methanol to make clean gas. The purified gas enters the methanation unit to synthesize methane and produce high-quality natural gas; In addition to the main product of natural gas, the purification plant produces acidic gas rich in hydrogen sulfide, which can be recycled to produce sulfur, and other branch lines also produce by-products such as naphtha, tar, and crude phenol. In this process, the most important wastewater treatment problems can be solved through the treatment of phenolamine recovery device, physical and chemical treatment of wastewater, biochemical treatment, advanced treatment and partial membrane treatment.

At present, China's natural gas production is mainly fossil energy extraction, coal-to-natural gas has just started, and has not formed a market supply, even if several projects under construction are put into production recently, its market share is small. Natural gas markets and pricing are dominated by governments and petrochemical production operators. From the price point of view, China's current fossil energy mining natural gas gate price (discount standard state) is about 1.20 yuan/m3, coal-to-natural gas can not compete with this. Taking the 4 billion m3 / year coal-to-natural gas project as an example, its total investment is about 22 billion yuan. The subscript table lists the competitive relationship between coal-to-natural gas and imported LNG. The improvement of natural gas price formation mechanism will be conducive to improving the economy of coal-to-natural gas projects.

3. Coal to ethylene glycol: the market gap is large, with a certain cost advantage

Ethylene glycol is an important chemical raw materials and strategic materials, mainly used in the production of polyester, polyester resin, hygroscopic agent, plasticizer, surfactant, synthetic fiber, cosmetics and explosives, and used as dyes, inks and other solvents, preparation of engine antifreeze, gas dehydrating agent, manufacturing resin, but also used in cellophane, fiber, leather, adhesive wetting agent. Coal to ethylene glycol is the production of ethylene glycol by coal instead of petroleum ethylene, and the commonly referred to coal to ethylene glycol technology mainly refers to oxalate ester method.

Oxalate method, that is, using coal as raw material, CO and H2 are obtained through gasification, transformation, purification and separation and purification, in which CO is combined into a catalytic couple and refined to produce oxalate, and then hydrogenated with H2 and refined to obtain polyester glycol. The complete set of technology in the implementation of Danyang, Jiangsu Province through the Chinese Academy of Sciences organization of the results appraisal, marking China in the world's first to achieve a full set of "coal to ethylene glycol" technical route and industrial application, is a world's first technology with independent intellectual property rights.

4. Coal-to-oil products: low conversion efficiency and large technical bottleneck

Coal-to-oil is a technology of producing oil and petrochemical products through chemical processing of coal as raw material. Coal to oil mainly includes direct coal liquefaction and indirect coal liquefaction two technical routes. Direct coal liquefaction refers to the direct synthesis of liquid hydrocarbon fuel by catalytic hydrogenation under high temperature and high pressure, and the removal of sulfur, nitrogen, oxygen and other atoms. The synthesis technology has poor adaptability to the types of coal, harsh reaction and operation conditions, high content of aromatics, sulfur, nitrogen and other impurities, low cetane number, and difficult to burn directly on the engine.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

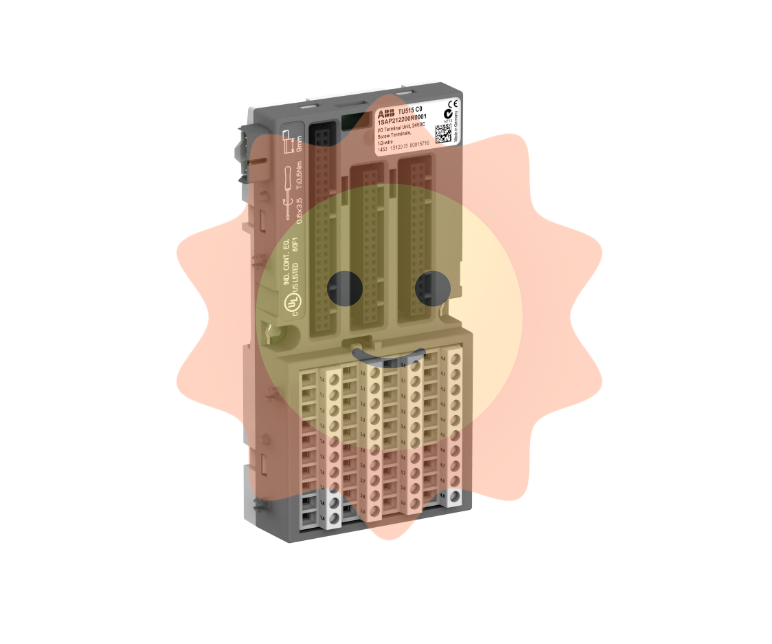

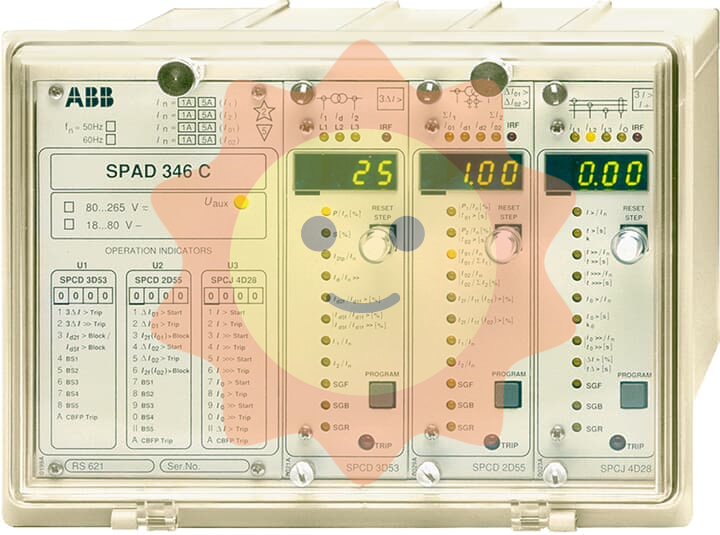

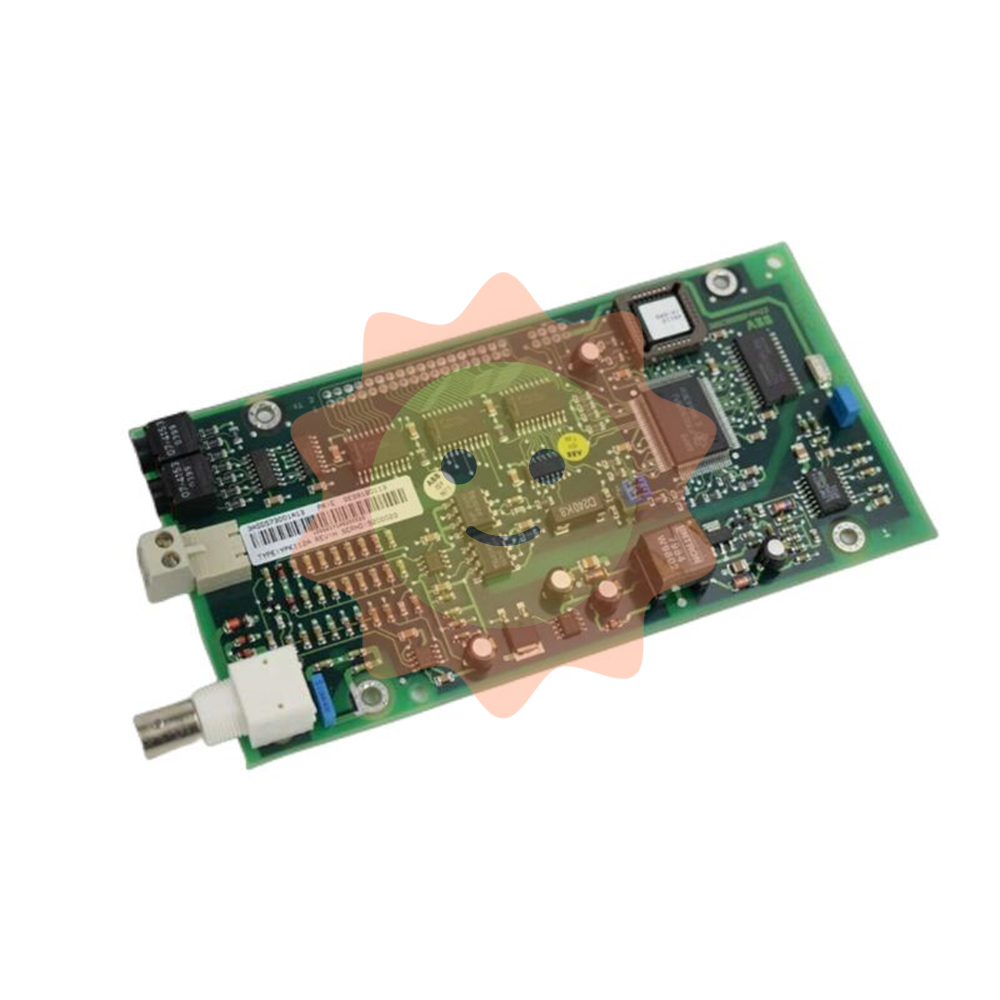

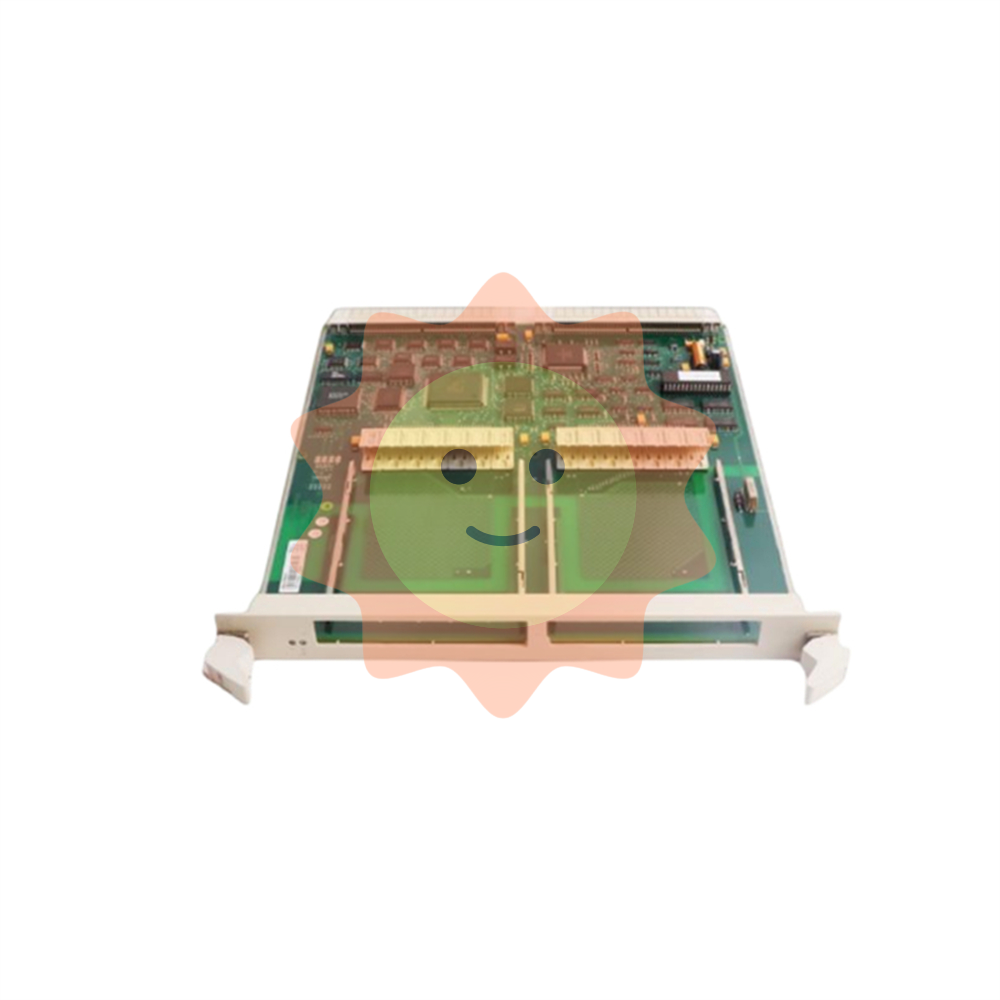

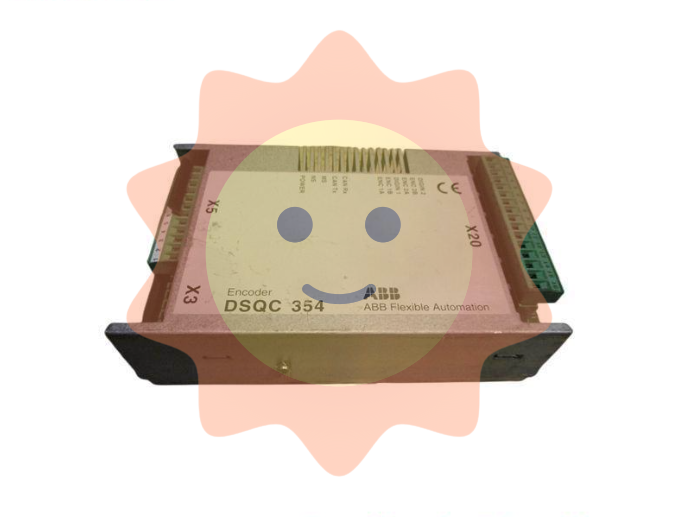

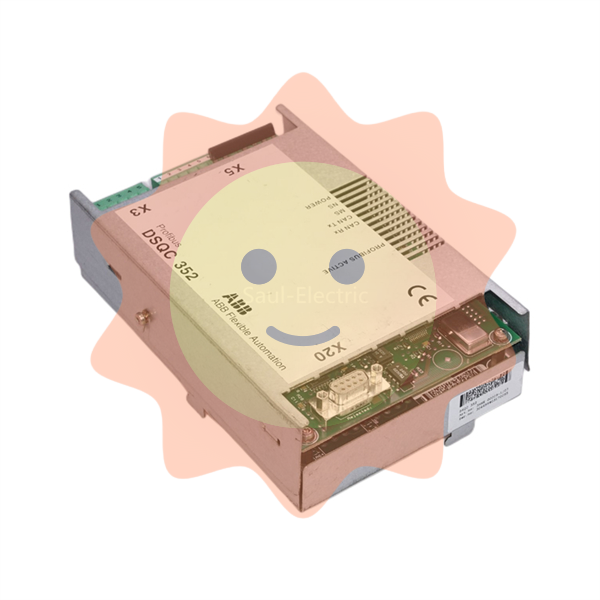

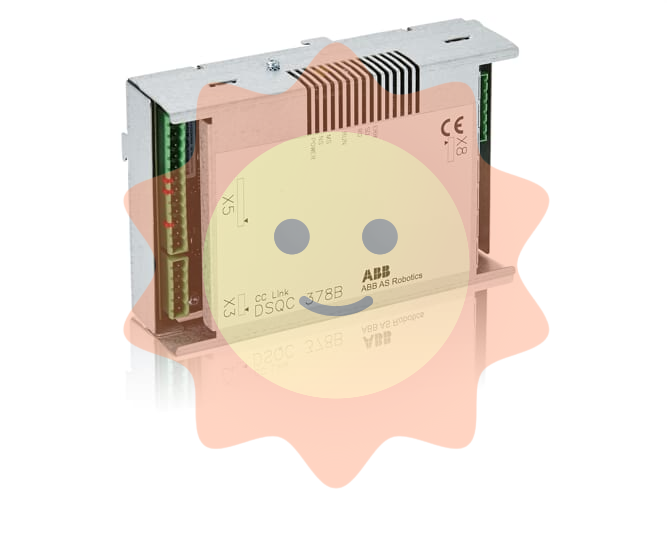

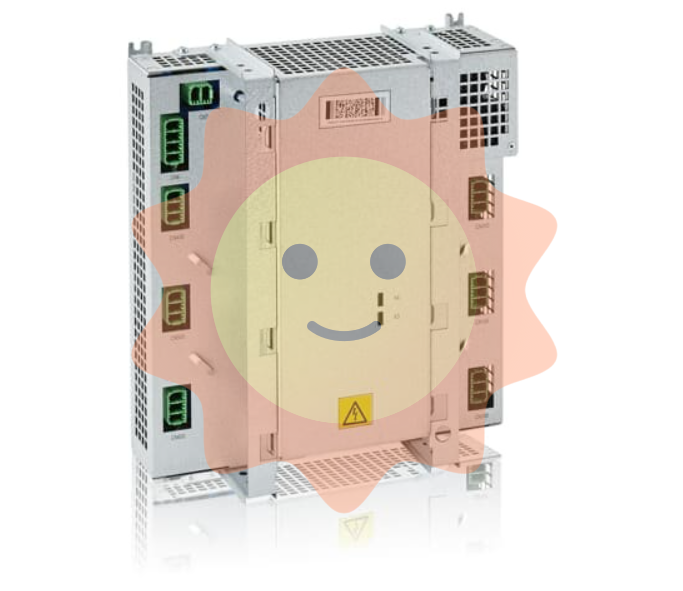

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

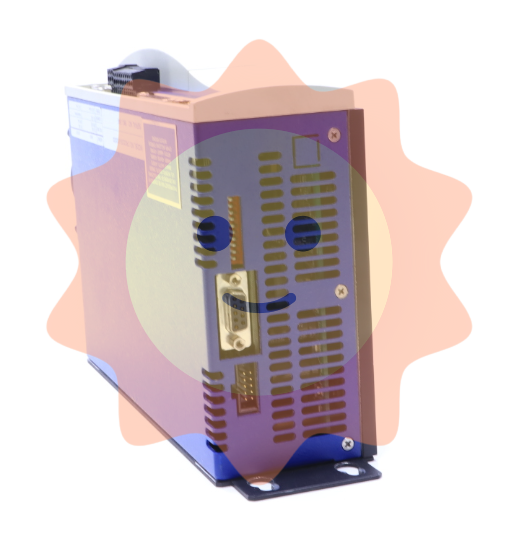

- PLC

- DCS

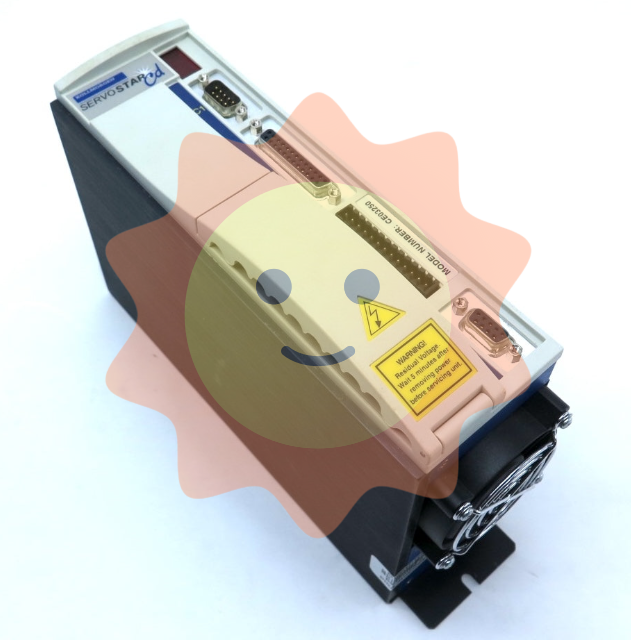

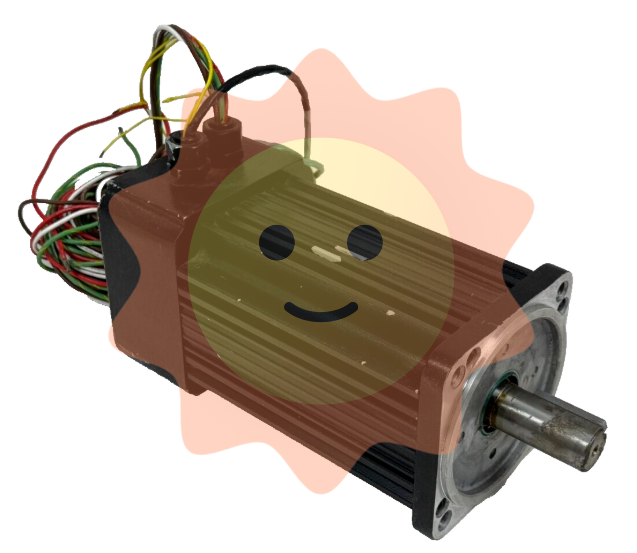

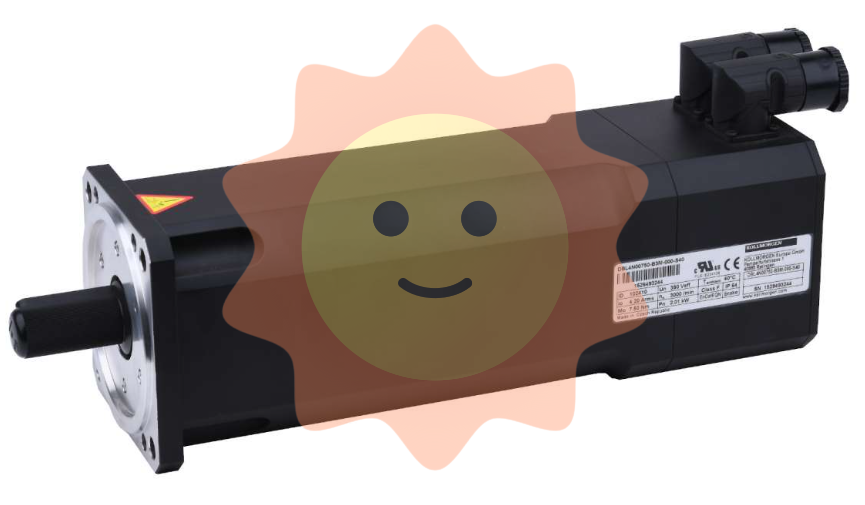

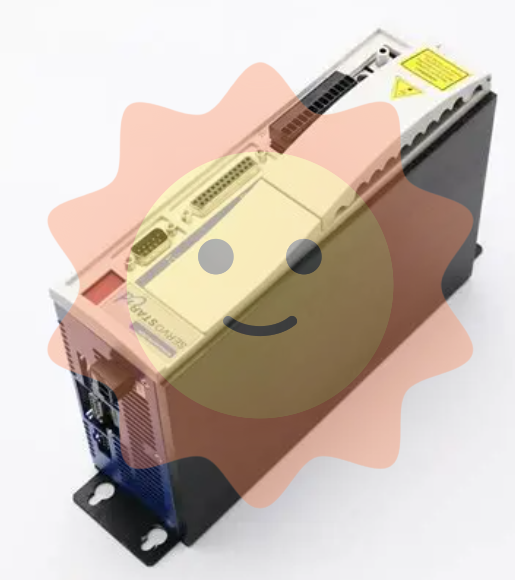

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com