ABB is a global technology leader transforming society and industry for a more efficient and sustainable future.

By integrating smart technology into electrical, robotics, automation and motion control products and solutions through software, ABB continues to push the boundaries of technology and improve performance to new heights. Discrete Automation & Motion Control: The Discrete Automation & Motion Control Division provides products, solutions and related services that help customers improve production and energy efficiency. Its motors, generators, drivetrains, programmable logic controllers, power electronics and robotics products are widely used in the automation fields of power, motion and control. The business unit's leadership position in the wind turbine industry and its growing product line in the solar energy sector will further promote the development of Discrete Automation & Motion Control's existing technologies, channels and operating platforms in the industrial sector.

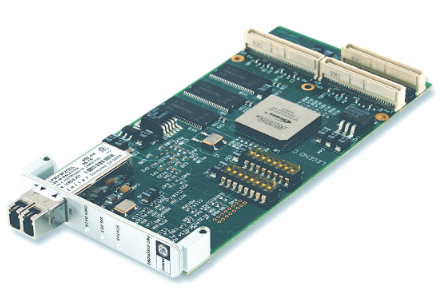

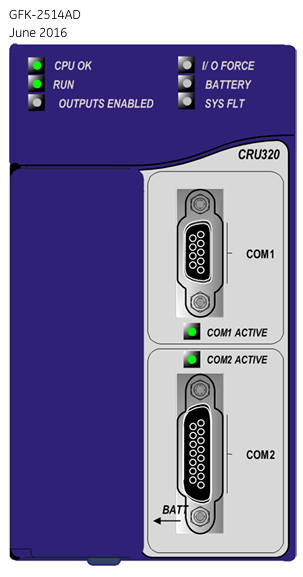

ABB robots provide a rich I/0 communication interface, which can easily realize the communication table with peripheral devices.

Description of ABB robot I/O communication interface

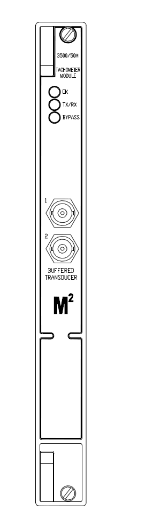

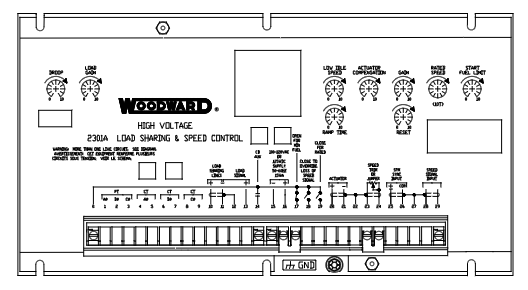

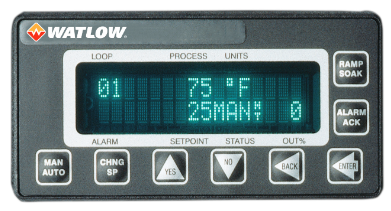

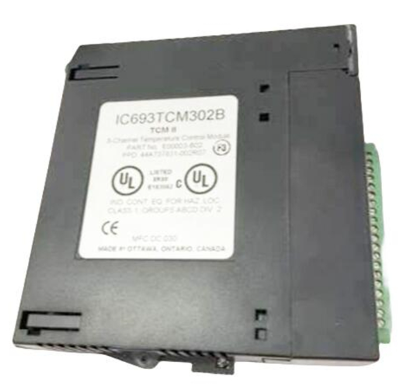

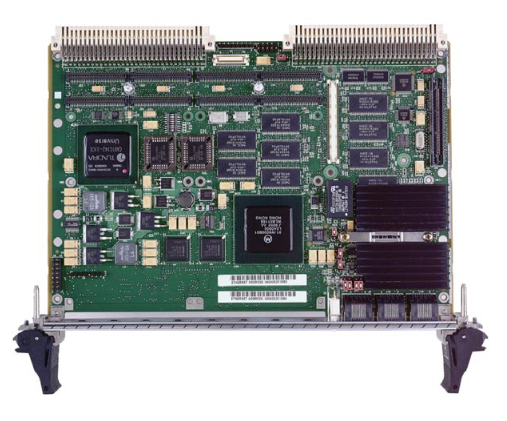

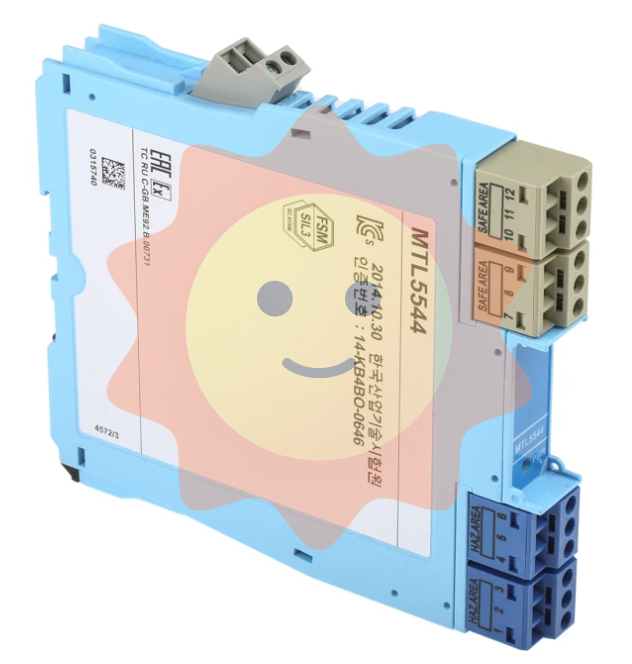

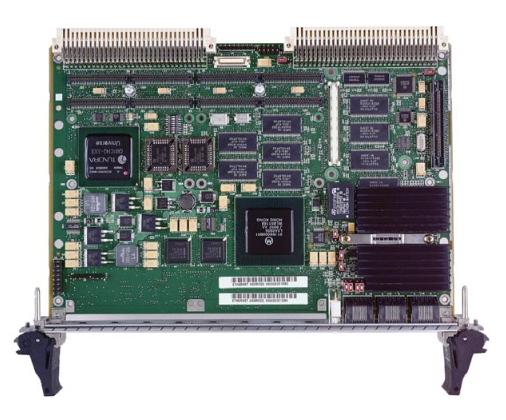

1. ABB standard I/O board provides common signal processing including digital input di, digital output do, analog input ai, analog output A0, and conveyor chain tracking.

2. ABB robot can choose standard ABB PLC, which saves the trouble of setting up communication with external PLC, and can realize PLC-related operations on the robot's teaching device.

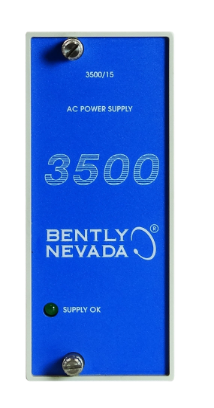

For interference, the following measures should be considered in the implementation of the project:

1) In the system structure design and equipment selection, fully consider environmental adaptability and electromagnetic compatibility;

2) The use of good performance of the power supply, the interference introduced by the power grid;

3) Reasonable selection and laying of cables and wires;

4) Isolation device or filter device is adopted in hardware;

5) Take measures to improve the reliability of the software, such as digital filtering, timing correction reference point potential, information redundancy, etc.

6) Correctly select the grounding method, generally using one point grounding and one point grounding in series.

How can automation improve logistics performance?

Four ways robots can improve logistics operations

Whether in the field of FMCG terminal operations, retail distribution centers, e-commerce fulfillment service centers or parcel sorting venues, robotic automation technology can play a different role. Across all logistics functions, the four key areas of product handling and sorting are as follows:

Material pickup: Robotic material pickup is equipped with a high-speed vision system to recognize product codes or other data, is reliable, and can pick up items of different weights within the load capacity.

Palletizing, unpalletizing, repalletizing: Whether it's boxes or handling boxes (the recyclable systems increasingly chosen by retailers and other businesses), robots are a mature option for palletizing and unpalletizing operations. At manufacturers' end of production lines, distribution centers and other application scenarios, robotic systems enable fast palletizing based on programmed pallet patterns. In addition to providing a reliable and safe pallet setup, the robot also avoids the operational problems that can arise during manual handling.

Robotic access systems: In e-commerce environments where multiple products need to be accurately picked and order information consolidated for shipment, robotic access systems are valuable by using coded data to identify, temporarily store and match items. Also, the ability to reliably perform repetitive tasks remains a major advantage of robotic systems.

Choose Xiamen control Smith after sale worry

Excellent product quality

Only cooperate with manufacturers of first-line brands in the industry

Imports/Products

Good pre-sale service

Communicated with customers repeatedly about product model, quality, price and delivery date

Work with the customer to determine the best solution

Address user concerns in advance

Business execution in place

Ordered products delivered on time

Make perfect delivery plan to ensure the time limit

Assist users to handle the acceptance procedures

Perfect after-sales service

During the warranty period, problems will only be replaced and not repaired

Never put a problem on the back of your head

Service hotline 7x24 hours service

Solemn promise

1. All the items sold by the company, module card parts, etc., the quality problems arising from normal use during the warranty period are replaced free of charge, and there is no evasion.

2. For materials and equipment that have not been discontinued beyond the warranty period, only the cost of relevant parts will be charged for quality problems.

3. Provide replacement models and equipment replacement process services for discontinued materials and equipment.

4. Customers have purchased materials and equipment, lifetime free upgrade system software, related technical information provided free of charge.

5. Visit the use of materials purchased by customers from time to time, and solve any problems in time.

6. The company hotline provides 24-hour service, and the questions raised by customers are answered within 1 hour.

7. Not done, the company spirit of "thoughtful service, responsible to the end" attitude, from the customer's point of view to solve the problem, with serious and rigorous enterprise style, dedicated to each customer service.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com