Manufacturers

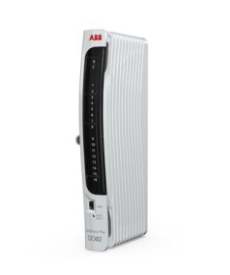

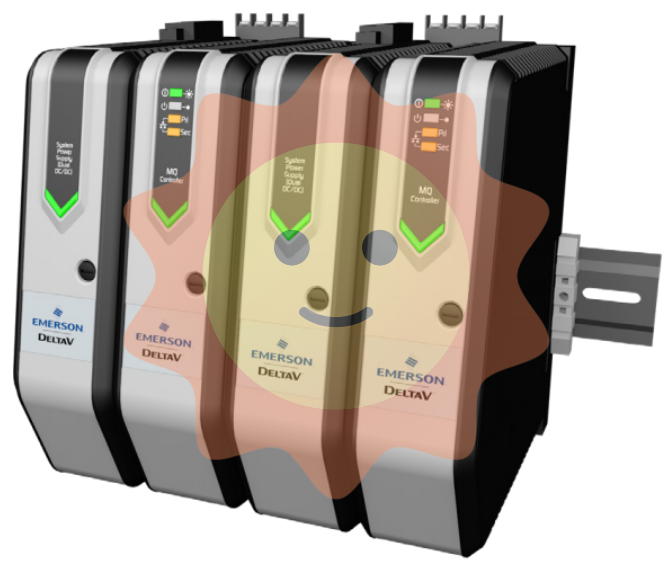

ABB

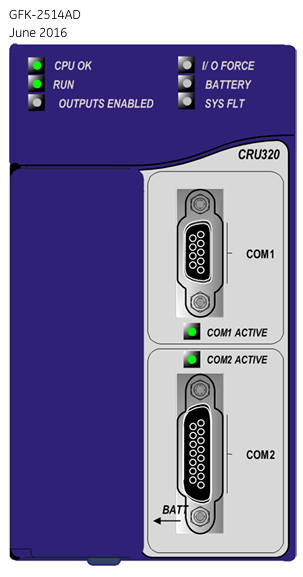

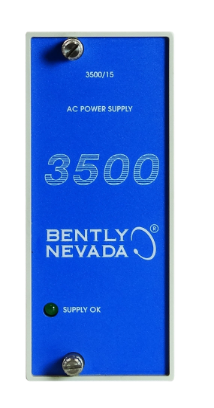

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Additional Information

Eight 24 VDC inputs/Six relay outputs, power supply is 230 VAC

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 1 lbs 14.1 oz (0.9kg )

Tariff Code: 8537109060

Country of Origin: France

Ships from Webster NY, USA

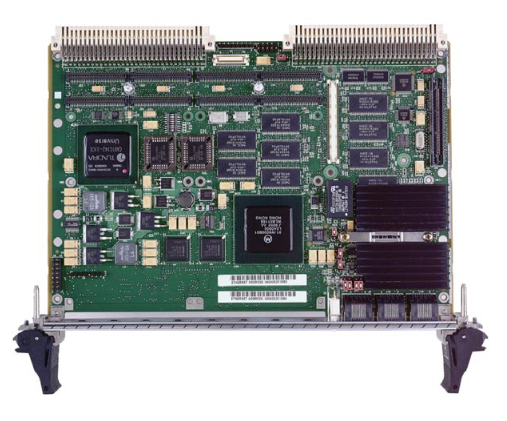

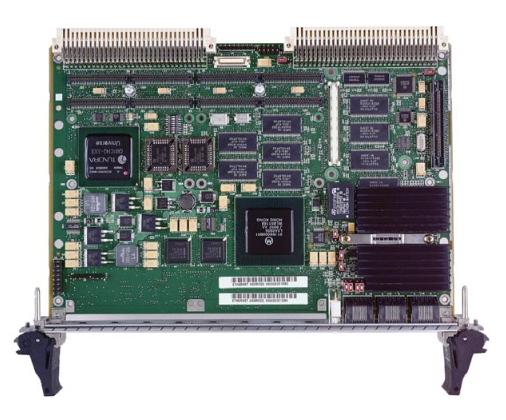

ABB 1SBP260014R1001 07KR51 Advant Controller 31 Basic Unit

Basic Information

Model & Series:

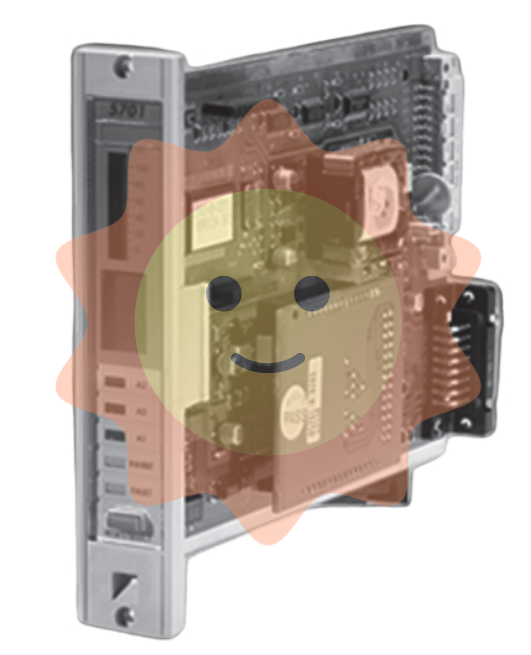

The unit model is 1SBP260014R1001 and belongs to ABB's 07KR51 Advant Controller 31 Basic Unit. In industrial automation control systems, the basic unit is the core component that provides the basic control and data processing functions for the operation of the entire system.

Appearance and size guess:

In terms of function and practical application scenarios, it is probably a rectangular shaped unit. Its length is probably around 30 - 40 cm, its width around 20 - 30 cm, and its thickness may be between 10 - 20 cm. The weight is estimated to be in the range of 3 - 6 kg, which would allow for easy mounting in a control cabinet or console, and would provide good stability in industrial environments.

Origin speculation:

ABB's high-end industrial control equipment is usually produced in regions with advanced industrial manufacturing technology, probably from European countries such as Sweden. These regions have advanced electronics manufacturing technologies and strict quality control systems, which help to ensure the high quality and reliability of the basic unit, enabling it to adapt to complex industrial environments.

Performance Features

Control function:

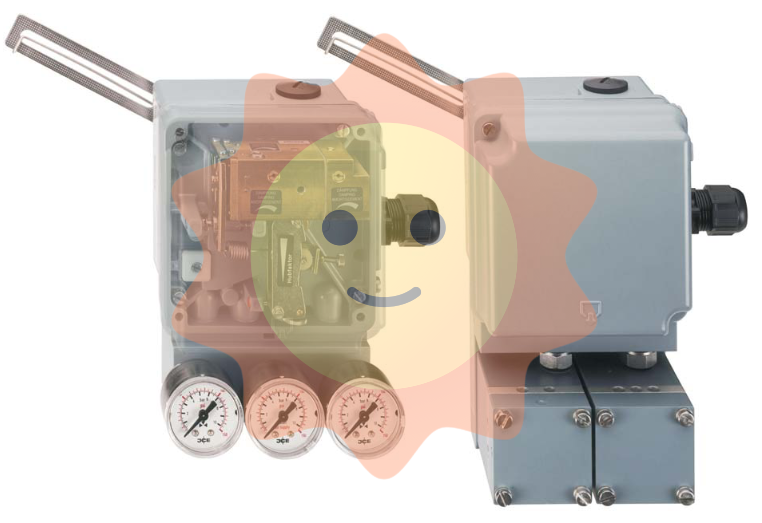

The unit is equipped with powerful control capabilities and is capable of executing complex control algorithms and logic operations. It can process a variety of input signals, including digital signals (e.g. digital output from switches and sensors) and analogue signals (e.g. analogue output from temperature and pressure sensors). According to the preset control strategy, through the internal processor and memory unit, it generates output signals to control the operation of industrial equipments, such as starting and stopping of motors and opening adjustment of valves.

It supports various control modes, such as open-loop control and closed-loop control. In closed-loop control mode, it receives feedback signals, such as actual temperature, pressure or speed signals, compares them with the set values, and then adjusts the outputs through control algorithms such as PID (Proportional-Integral-Differential) to stabilise the actual physical quantities around the set values. This type of control mode is very important for precise control of process parameters in the chemical, power and other process industries.

Data processing and storage capability:

It is able to process a large amount of data efficiently. For the input analogue signals, it can carry out high-precision analogue-to-digital conversion to convert continuous analogue signals into digital signals for processing. At the same time, it also has a certain data storage capacity, and can store control programmes, configuration parameters, historical data and other information. These stored data can be used for fault diagnosis, data analysis, process optimisation and other purposes. For example, the stored historical data can help analyse the operating trend of the equipment and detect potential problems in advance.

Communication interface diversity:

Support for a variety of communication interfaces is key to enabling integration with external devices and systems. These may include Ethernet interfaces, which are used to access the factory's local area network (LAN) for high-speed communication with the host computer, other controllers, or remote monitoring systems; RS-485 interfaces, which are suitable for connecting to some traditional industrial devices, such as sensors and actuators with RS-485 communication; and support for industrial Ethernet protocols, such as Profinet, EtherNet/IP, etc., which are used to build high-performance industrial automation networks. It is used to build high-performance industrial automation networks.

Reliability and Stability:

A highly reliable design is adopted to ensure stable operation in industrial environments. In terms of hardware, high-quality electronic components are used with good anti-interference capability to work normally in harsh industrial environments (e.g. high temperature, high humidity, strong electromagnetic interference, etc.). For example, special heat dissipation designs may have been adopted to ensure that the equipment will not fail due to overheating during prolonged operation. Meanwhile, in terms of software, there may be a perfect fault detection and recovery mechanism, which can automatically try to recover or take corresponding emergency measures to guarantee the continuity of the control process when there is a programme error or communication interruption.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com