Manufacturers

ABB

Model(s)

ABB Advant Controller 31, ABB Advant OCS

Estimated Shipping Size

Dimensions: 4.0" x 4.0" x 5.0"

(10.2 cm x 10.2 cm x 12.7 cm)

Weight: 0 lbs 12.9 oz (0.4kg )

Tariff Code: 8538907080

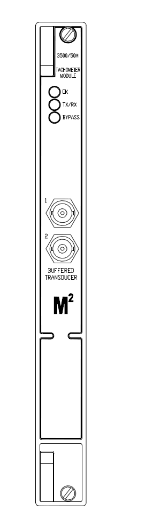

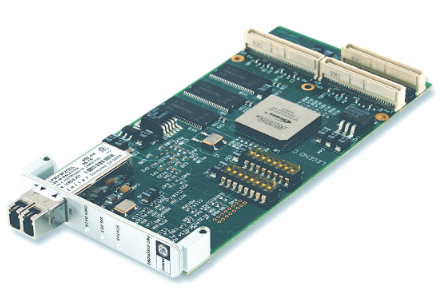

ABB 1SBP260103R1001 XM06B5 Extension Unit

Basic Information

Model and Series:

The model number 1SBP260103R1001 belongs to ABB's XM06B5 Extension Unit. In industrial automation systems, extension units are mainly used to extend the functionality of the main controller, for example by adding input and output interfaces, communication interfaces or other special function modules.

Appearance and size guess:

Considering its function as an expansion unit and ease of installation, it is probably a compact circuit board module. The appearance is probably rectangular in shape, perhaps around 10 - 15 cm in length, 8 - 12 cm in width, and 3 - 6 cm in thickness. The weight is estimated to be relatively light, probably in the region of 0.3 - 0.6kg, allowing for easy mounting in slots in industrial control cabinets or integration with other modules.

Presumed origin:

ABB industrial equipment of this type is usually produced in regions with high levels of industrial manufacturing, most likely from European countries such as France. These regions have advanced electronics manufacturing technology and strict quality control systems, which makes the XM06B5 expansion unit likely to have a high level of quality and stability, able to adapt to complex industrial environments.

Performance Features

Function Expansion:

A variety of functional extensions are provided. This may include the addition of analogue input/output (AI/AO) interfaces, digital input/output (DI/DO) interfaces or special function interfaces such as high speed counter interfaces, pulse width modulation (PWM) interfaces, etc. The exact number and type of interfaces will vary depending on the product design, but these additions allow the system to connect more external devices, such as sensors, actuators, etc., or to implement more complex control functions. For example, in an automated packaging line, the expansion unit can be used to connect more photoelectric sensors to detect the position of packaging materials, as well as adding output interfaces to control the movement of the packaging machinery, and potentially providing PWM interfaces for controlling the speed of motors.

Interface characteristics and compatibility:

The electrical characteristics of the additional interfaces conform to industry standards and are compatible with many types of industrial equipment. The analogue inputs may support a variety of signal levels such as 0 - 10V or 4 - 20mA for receiving analogue data from sensors such as temperature, pressure, flow, etc. The digital inputs may support common industrial inputs and outputs for controlling motor speed. The digital inputs may support common industrial voltage signals such as 24V DC. These interfaces can be seamlessly connected to other ABB controllers, I/O modules and third-party industrial equipment for easy system integration. For example, it is possible to plug a new sensor with an analogue output into an existing ABB automation control system, enabling the sharing of data and expansion of system functionality.

Communication and data transfer capability:

Good communication capability with the main controller ensures accurate data transfer. It may be connected to the main controller through a high-speed data bus to support fast reading and writing of data. During data transmission, reliable communication protocols and error correction mechanisms are used to prevent data loss or errors. For example, in an automation control system, when the main controller needs to obtain data from sensors connected to the expansion unit or send control commands to an actuator, it is able to interact with data efficiently over a stable communication link. In addition, it may also support some external communication interfaces, such as RS-232, RS-485 or Ethernet interfaces, for communication with other remote devices or systems.

Reliability and Environmental Adaptability:

High-quality electronic components and rugged enclosure design are used to adapt to the harsh conditions of industrial environments. In terms of temperature adaptability, it is able to work normally in a wide temperature range (e.g. - 10°C - 50°C) to adapt to the high or low temperature environment that may occur in industrial sites. It also has a certain degree of anti-electromagnetic interference ability, able to operate stably in industrial environments where a large number of electrical equipment and electromagnetic radiation exist, avoiding data errors or module failures caused by electromagnetic interference. The housing, which may be made of metal or high-quality engineering plastics, is resistant to a certain degree of mechanical shock, vibration and dust intrusion.

Areas of application

Industrial automated production line applications:

In automotive manufacturing lines, interfaces are used to extend the control system. For example, in the automotive assembly process, the expansion unit can be used to connect more control interfaces for power tools, such as electric screwdrivers, pneumatic wrenches, etc. The unit can also be used to access more sensors to detect the assembly quality and position of the parts, to ensure that the automotive assembly process is efficient and precise. In addition, its special function interfaces, such as high-speed counter interfaces, can also be used to monitor the rotational speed of rotating equipment in the production process of automotive parts, such as motors and gears.

Applications in process control systems:

In the chemical, oil and gas process industries, it is used to extend the interface of process control equipment. For example, in the control system of a chemical reactor, the extension unit allows the connection of more temperature and pressure sensors, as well as the control of more actuators such as inlet and outlet valves and stirring motors, thus enabling finer control of the reaction process. Its analogue input interface can receive more accurate temperature and pressure sensor signals, digital output interface can control more valves and motors, and the communication interface is convenient for data interaction with remote monitoring system to ensure the safe and stable operation of the reaction process.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com