The DO814 I/O system, as a distributed expansion unit of the AC 800M control system, is positioned as a "bridge connecting field devices and control cores" and undertakes the task of "transmitting and receiving" digital signals - on the one hand, it collects and transmits status signals of field devices (such as valve switch status and sensor trigger signals) to the controller, and on the other hand, it receives command signals from the controller to drive actuators (such as relays and solenoid valves) to act. Its design philosophy revolves around "industrial grade reliability, flexible adaptability, and convenient operation and maintenance". It adopts a modular structure and redundant design, supports hot plugging function, and can complete module replacement without interrupting system operation, greatly improving system availability and maintenance efficiency.

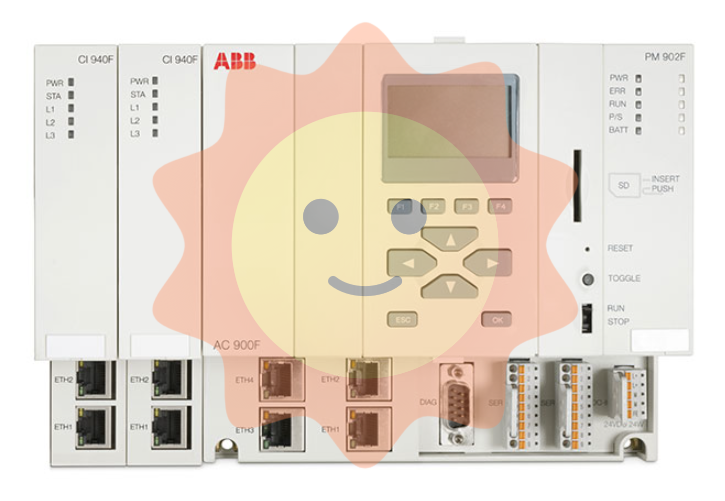

ABB DO814 Input/Output System

Core positioning and design philosophy of the product

The DO814 I/O system, as a distributed expansion unit of the AC 800M control system, is positioned as a "bridge connecting field devices and control cores" and undertakes the task of "transmitting and receiving" digital signals - on the one hand, it collects and transmits status signals of field devices (such as valve switch status and sensor trigger signals) to the controller, and on the other hand, it receives command signals from the controller to drive actuators (such as relays and solenoid valves) to act. Its design philosophy revolves around "industrial grade reliability, flexible adaptability, and convenient operation and maintenance". It adopts a modular structure and redundant design, supports hot plugging function, and can complete module replacement without interrupting system operation, greatly improving system availability and maintenance efficiency.

This system is compatible with ABB's proprietary mainstream industrial communication protocols such as PROFIBUS DP and EtherNet/IP, and can quickly integrate into various automation control system architectures, achieving seamless communication with upper computers, controllers, and other I/O modules, providing convenience for building distributed and networked control systems.

Core technical parameters

model

DO814 (digital output module, matched input module can form a complete I/O system)

Module Type

Digital output module, can be combined with digital input modules such as DI814 to form an I/O system

Number of output channels

16 independent output channels, each can be configured and controlled separately

Output signal type

Relay output (normally open contact), supports dry contact signal output

Output load capacity

AC 250V/5A, DC 30V/5A (maximum load per circuit)

response time

Output action response time ≤ 10ms, meeting the requirements of fast control

communication interface

Supports industrial communication protocols such as PROFIBUS DP, EtherNet/IP, Modbus TCP, etc. (depending on configuration selection)

working power supply

System power supply: DC 24V ± 10%; Channel power supply: AC 220V/DC 24V (switchable)

working environment

Temperature: 0-60 ℃; Humidity: 5% -95% RH (no condensation); Non corrosive gas and dust environment

Protection level

The module itself has an IP20 rating (to be installed inside the control cabinet), and the connection terminals are designed to prevent accidental insertion

Installation method

Standard DIN rail installation (35mm), supports parallel installation with other AC 800M series modules

special function

Support hot plugging, channel fault diagnosis, and power redundancy backup

Core functional advantages

1. High reliability and redundancy design to ensure stable system operation

The DO814 I/O system adopts industrial grade core chips and high-quality relays, which have undergone strict high and low temperature aging, vibration impact, and electromagnetic compatibility testing. The average time between failures (MTBF) exceeds 200000 hours. The system supports power redundancy and communication redundancy configuration. When the main power supply or main communication link fails, it can automatically switch to the backup circuit with a switching time of ≤ 100ms, ensuring uninterrupted signal transmission and control instruction execution, meeting the strict requirements of critical industries such as chemical and power for system continuity.

2. Multi channel independent control, suitable for complex control scenarios

The 16 output channels are independent of each other, and each channel can be individually configured with an output status (on/off) through a controller, supporting multiple control modes such as jog and hold. The channels are designed with electrical isolation, with an isolation voltage of ≥ 2500V AC, which can effectively avoid the overall system paralysis caused by a channel failure, and prevent interference from strong electrical signals on site to the control circuit, thus improving the system's anti-interference ability.

3. Comprehensive fault diagnosis and warning functions

The system has comprehensive fault diagnosis capabilities and can monitor key parameters such as channel output status, relay life, power supply voltage, and communication links in real time. When there are faults such as channel short circuit, relay adhesion, power supply abnormality, etc., the fault code and alarm information will be immediately sent to the upper computer through the communication interface. At the same time, the LED indicator lights on the module panel will flash correspondingly (such as red indicator lights indicating channel faults and yellow indicator lights indicating communication abnormalities), which is convenient for operation and maintenance personnel to quickly locate the fault point and handle it.

4. Flexible expansion and compatibility, reducing system integration costs

As a standard module of the AC 800M control system, DO814 can be flexibly combined with digital input modules (DI814) and analog I/O modules (AI810/AO810) of the same series to configure I/O points according to on-site requirements and avoid resource waste. At the same time, it is compatible with multiple mainstream industrial communication protocols and can seamlessly integrate with third-party PLC and SCADA systems without the need for additional protocol conversion modules, reducing system integration complexity and costs.

5. Convenient operation and hot swappable design to improve maintenance efficiency

The module supports hot swapping function, and operation and maintenance personnel can replace faulty modules without stopping the machine while the system is running normally, greatly reducing maintenance time. The module adopts a front wiring method, and the terminals have anti misplacement and locking design, ensuring firm and reliable wiring; The LED indicator lights on the panel can intuitively display the power status, communication status, and working status of each channel of the module, making it easy for on-site personnel to quickly troubleshoot problems.

Applicable scenarios and typical applications

The DO814 I/O system, with its high reliability and flexible scalability, is widely used in various industrial automation control scenarios, especially in fields that require precise digital quantity control and status monitoring. Typical applications include:

1. Power industry: Control of boiler auxiliary equipment in thermal power plants (such as start stop control of coal feeders and induced draft fans), monitoring and control of switch status in substations, and ensuring the continuity and safety of power supply through redundant design.

2. Chemical industry: Valve switch control in chemical production workshops (such as the start and stop of feed valves and discharge valves), monitoring of the operating status of pump equipment, and emergency shutdown control in conjunction with Safety Instrumented Systems (SIS) to prevent dangerous working conditions from occurring.

3. Metallurgical industry: Control of blast furnace feeding system in steel plants, equipment linkage control of steel rolling production lines, and precise scheduling of complex production processes through multi-channel independent control.

4. Water treatment industry: Control of aeration tank fans, sedimentation tank discharge valves, and status collection and feedback control of water quality monitoring equipment in sewage treatment plants to achieve automated operation of the sewage treatment process.

5. General industry: The start stop control of conveyor belts in automated production lines, the action control of packaging equipment, and the driving of various indicator lights and alarm devices provide basic control support for the efficient operation of production lines.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-