The ICSF08D1 high-speed counter, as the "precision measurement unit" in industrial automation systems, is positioned to solve the problem of pulse signal acquisition and counting in high-speed motion scenarios, filling the performance gap of ordinary counters in high-frequency signal processing. Its design philosophy revolves around "precision, stability, flexibility, and ease of use", using dedicated high-speed signal processing chips and optimized circuit design to effectively process high-frequency pulse signals, avoiding signal loss or counting errors; Simultaneously adopting a modular structure and standardized communication interface, it supports seamless integration with various PLCs, control systems, and upper computers, adapting to the automation control needs of different industries.

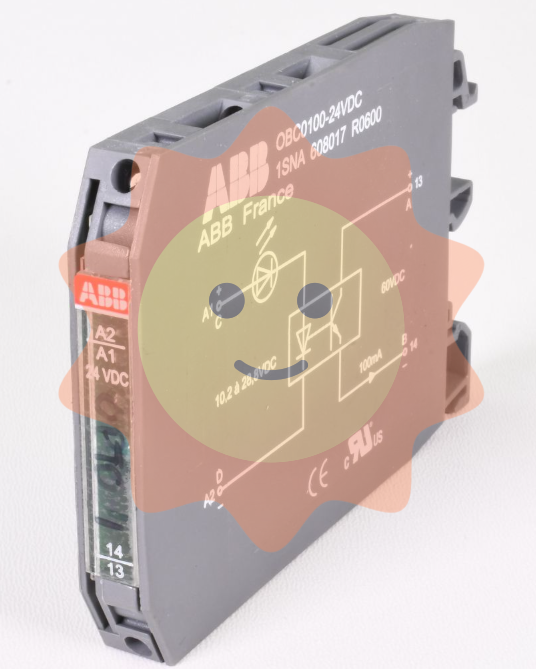

ABB ICSF08D1 FPR3323101R1012 24VDC high-speed counter

Core positioning and design philosophy of the product

The ICSF08D1 high-speed counter, as the "precision measurement unit" in industrial automation systems, is positioned to solve the problem of pulse signal acquisition and counting in high-speed motion scenarios, filling the performance gap of ordinary counters in high-frequency signal processing. Its design philosophy revolves around "precision, stability, flexibility, and ease of use", using dedicated high-speed signal processing chips and optimized circuit design to effectively process high-frequency pulse signals, avoiding signal loss or counting errors; Simultaneously adopting a modular structure and standardized communication interface, it supports seamless integration with various PLCs, control systems, and upper computers, adapting to the automation control needs of different industries.

This device is designed to address the complex electromagnetic environment and power supply fluctuations in industrial sites. It is equipped with comprehensive signal filtering and power stabilization modules to ensure stable operation even under harsh working conditions; Equipped with an intuitive operation panel and flexible parameter configuration method, it reduces the operational threshold for operation and maintenance personnel, achieving rapid debugging and daily management.

Core technical parameters

Model identification

ICSF08D1 (core model); FPR3323101R1012 (Order Number)

power supply

DC 24V ± 10%, ripple ≤ 100mV, power consumption ≤ 10W

Counting type

Incremental counting, absolute counting (supports multiple encoder signals)

Counting frequency

Single channel maximum counting frequency 1MHz, supports 8 parallel counting channels (each independent frequency ≤ 500kHz)

Input signal type

Differential signal (RS422/RS485), open collector signal, compatible with NPN/PNP sensors

Counting range

32-bit unsigned integer, range 0-4294967295

Counting mode

Counting up, counting down, bidirectional counting up and down, cycle counting, frequency measurement, etc

output interface

4-channel transistor output (DC 24V, maximum load 1A), supporting counting standard alarm and status output

communication interface

RS485 interface (supporting Modbus RTU protocol), EtherNet/IP (optional), for data upload and remote control

working environment

Temperature: -20 ℃ -60 ℃; Humidity: 10% -90% RH (no condensation); Non corrosive gas and strong dust environment

Protection level

IP20 (module body), to be installed inside the control cabinet for use

Installation method

35mm standard DIN rail installation, installation depth ≤ 120mm

Calibration accuracy

Counting error ≤ ± 1 pulse (within the rated counting frequency range)

Core functional advantages

1. High frequency signal processing capability, accurate and error free counting

Using ABB's dedicated high-speed signal acquisition chip and digital filtering algorithm, a single channel can process up to 1MHz pulse signals. Even in the presence of slight jitter or interference in sensor signals, adaptive filtering technology can effectively eliminate noise and ensure accurate capture of pulse signals. The 32-bit counting chip supports a large counting range, which can meet the needs of long-term continuous counting and avoid data loss caused by counting overflow. The counting error is controlled within ± 1 pulse, fully meeting the measurement requirements of high-precision production scenarios.

2. Multi mode and multi-channel design, suitable for a wide range of scenarios

The device supports 8 independent counting channels, each of which can be configured with a separate counting mode (add/subtract/bidirectional counting), input signal type (differential/open collector), and triggering method. Multiple encoders or sensors can be connected simultaneously to achieve parallel counting of multiple production lines or devices. In addition, the built-in frequency measurement, cycle measurement, pulse width measurement and other extended functions can directly convert counting data into process parameters such as rotational speed (r/min) and linear velocity (m/s) without the need for additional calculations by the upper computer, simplifying the system control logic.

3. Improved alarm and linkage functions to enhance control accuracy

Support independent setting of upper and lower limit alarm thresholds and counting target values for each channel. When the counting reaches the set value or exceeds the threshold range, the equipment can directly link with on-site actuators (such as shutdown signals, alarm indicators, sorting devices) through transistor output, achieving closed-loop control of "counting judgment execution". For example, in the material packaging production line, when the count reaches the preset packaging quantity, the conveyor belt can be immediately triggered to stop, improving packaging accuracy and production efficiency. At the same time, alarm information can be uploaded to the upper computer through a communication interface, making it easier for management personnel to grasp the on-site status in real time.

4. Strong anti-interference and high reliability, suitable for harsh working conditions

In response to electromagnetic interference issues in industrial sites, the equipment adopts a dual isolation design for power and signal. The power isolation voltage is ≥ 2500V AC, and the signal isolation voltage is ≥ 1500V AC, which can effectively resist electromagnetic radiation interference generated by frequency converters, high-power motors, and other equipment. Internally, industrial grade components are used and undergo strict reliability tests such as high and low temperature cycling and vibration impact. The mean time between failures (MTBF) exceeds 150000 hours and can operate stably in low-temperature workshops at -20 ℃ or high-temperature production environments at 60 ℃.

5. Convenient configuration and data management to reduce operation and maintenance costs

Equipped with 4 LED display panels and 4 function buttons, operation and maintenance personnel can directly set counting parameters, calibrate equipment, and view real-time counting data through on-site buttons, making the operation intuitive and easy; Simultaneously supporting centralized management of multiple devices through ABB dedicated configuration software or remote parameter configuration on the upper computer. The device has a counting data power-off saving function, and the data can be saved for more than 10 years after a power outage to avoid production data loss caused by sudden power outages; Real time counting data, alarm logs, equipment status and other information can be uploaded to the SCADA system through communication interfaces, providing data support for production data analysis and process optimization.

Applicable scenarios and typical applications

The ICSF08D1 high-speed counter, with its high-frequency processing capability, multi-channel design, and high reliability, is widely used in various industrial scenarios that require precise counting and dynamic monitoring. Typical applications include:

1. Mechanical manufacturing industry: Monitoring the spindle speed of CNC machine tools (calculating speed through encoder signals), counting the number of teeth in gear machining, and counting the number of stamping times of stamping equipment to ensure the accuracy of machining precision and production capacity statistics.

2. Logistics and warehousing industry: Automated sorting line counting of package quantity, conveyor belt material conveying volume statistics, and three-dimensional warehouse stacker displacement positioning counting to achieve precise management of logistics sorting and warehousing.

3. Metallurgical industry: measuring the length of steel strips in steel plants (converting length through roller encoder signals), counting the number of steel pipes produced, and assisting in tension control of cold rolling production lines (adjusting tension through speed feedback) to improve the production accuracy of metallurgical products.

4. Electronics industry: counting chips in electronic component production lines, counting the number of PCB board conveyors, and counting the number of electrode cutting times in battery production to meet the high-capacity and high-precision counting needs of the electronics industry.

5. Packaging industry: Counting bottles and cans in food and beverage packaging lines, detecting the number of capsules in drug packaging, and counting the number of bags in daily chemical products to achieve precise control of packaging quantity and avoid missing or multiple packages.

Key points for installation and debugging

1. Installation specifications

-Installation environment requirements: Install the equipment in a closed control cabinet, avoiding direct sunlight, rainwater erosion, and dust accumulation; The control cabinet should have ventilation and heat dissipation functions to ensure that the temperature inside the cabinet does not exceed 60 ℃; Stay away from strong electromagnetic interference sources such as frequency converters and high-power contactors. If the installation distance is close, shielded cables should be used and grounding treatment should be done.

-Installation requirements for guide rails: Use 35mm standard DIN guide rails, and maintain a minimum heat dissipation gap of 10mm between the equipment and adjacent modules; The installation position should be firm to avoid loose wiring or counting errors caused by equipment vibration.

-Wiring specifications: The power line and signal line are separately wired, and shielded twisted pair cables are used to transmit sensor signals. The shielding layer is grounded at one end (grounding resistance ≤ 4 Ω); Strictly follow the terminal diagram to identify the wiring, distinguish the positive and negative poles of the power supply, signal input terminals, and output terminals, and avoid equipment damage caused by reverse connection; After the wiring is completed, it is necessary to check whether the terminal screws are tightened to prevent signal loss caused by poor contact.

2. Debugging steps

1. Pre power on inspection: Confirm that the power supply voltage is DC 24V, which is consistent with the rated voltage of the equipment; Check if the wiring is correct and if the shielding layer of the signal line is well grounded; Confirm that the sensor (such as encoder) matches the signal type of the device (differential signal/open collector).

2. Parameter initialization configuration: After power on, set device parameters through on-site buttons or configuration software, including communication address, counting mode (up/down counting), input signal type, upper limit of counting frequency, etc; Set signal filtering parameters according to the sensor model to avoid false counting caused by interference signals.

3. Signal connection test: Connect the encoder or sensor to the device signal input terminal, start the sensor, observe the real-time counting changes on the device LED display panel, and confirm whether the counting direction and value are correct; If the counting is abnormal, check the signal line connection or adjust the signal filtering parameters.

4. Alarm and linkage testing: Set the counting target value and alarm threshold, simulate the scenario where the counting reaches the target value, check whether the device transistor output is properly linked to the actuator, and confirm whether the upper computer can receive the alarm information; Test fault scenarios such as counting overflow and signal loss, and check whether the equipment fault diagnosis and alarm functions are normal.

5. Communication testing: Connect the device to the upper computer through Modbus RTU protocol or EtherNet/IP to test whether the transmission of real-time counting data, device status and other information is stable, ensuring that there is no delay or loss in data upload.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-