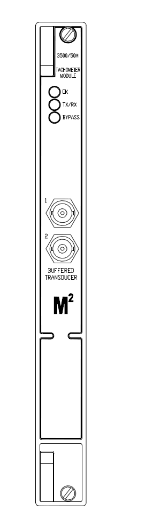

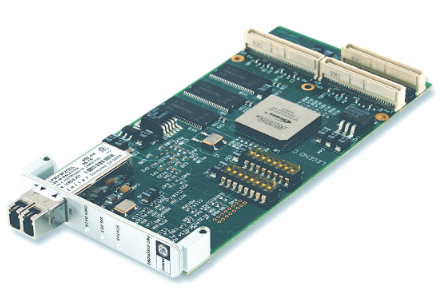

ABB INNPM12 Network Processor Module

Functional Characteristics

Data Processing and Transmission: As a network processor, it has powerful data processing capability to efficiently process various data in network communication, such as real-time acquisition, analysis and processing of signals from different devices, and ensure fast and stable transmission of data in the network to realize real-time data exchange between devices.

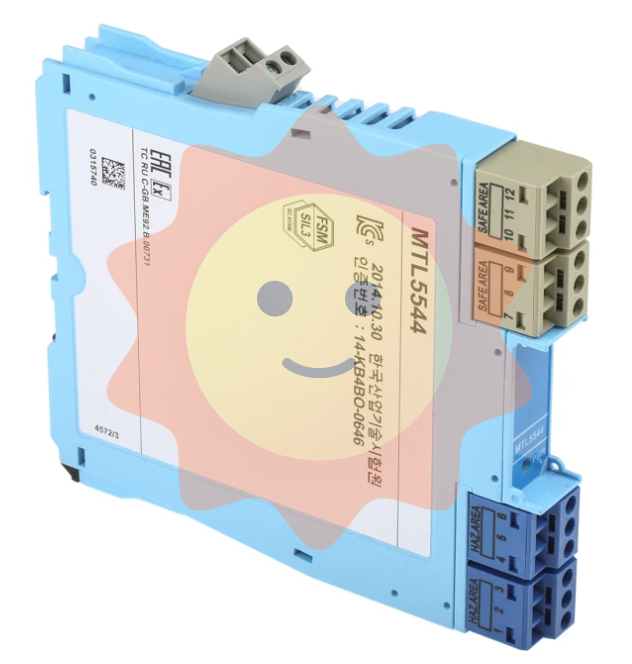

Protocol support: support for a variety of industrial communication protocols, such as Profibus, Modbus, Ethernet/IP, OPC, etc., can be seamlessly integrated and communicated with different manufacturers, different types of equipment and systems, to facilitate the construction and expansion of the system in the complex industrial automation environment.

Redundancy function: with hardware redundancy characteristics, through the full redundancy module configuration, in the event of failure of the main module, the standby module can quickly take over the work to ensure system continuity and reliability, and effectively reduce the production downtime caused by equipment failure.

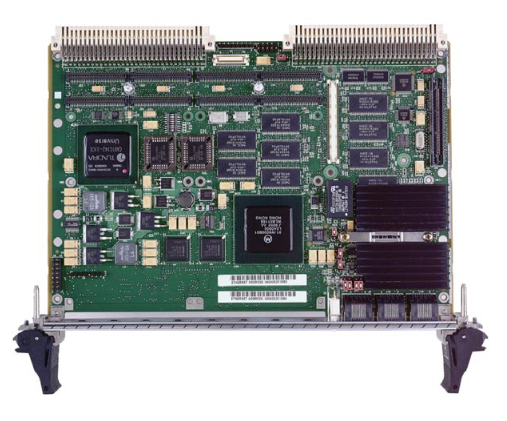

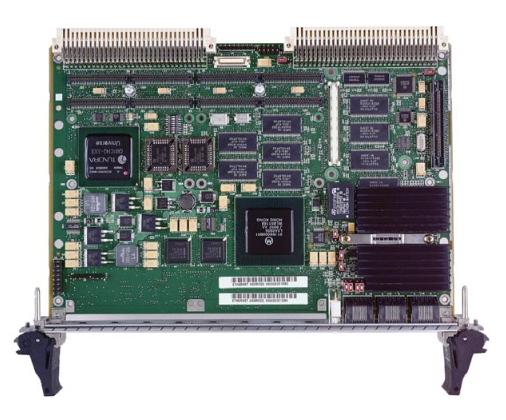

Technical Parameters

Physical dimensions: length 3.5cm, width 31.2cm, height 17.6cm, weight 0.26kg.

Power supply: 24V DC power supply, the operating voltage range is usually 18V to 30V, power consumption is about 20-30W, depending on the load and configuration.

Processor Type: Equipped with a high performance embedded processor, please refer to the product manual for specific model number.

Memory Configuration: Usually includes volatile and non-volatile memory for storing system data and configurations, which can meet the needs of storing configuration data, control programs and historical data.

Application Areas

Industrial automation: In the process control field of petroleum, chemical, electric power, water treatment, etc., it can be used as the core component of the control system, connecting with PLC, DCS, HMI and other equipment, realizing real-time monitoring, data acquisition and automation control of the production process, ensuring the safe, stable and efficient operation of the production process.

Intelligent Manufacturing: In the automated production line, it is responsible for coordinating the communication and data processing between robots, automation equipment, sensors, etc., realizing the intelligent scheduling and optimization of the production process, and improving the production efficiency and product quality.

Energy management: in the energy production, transmission and distribution system, it can be used to connect energy metering equipment, monitoring equipment and control system to realize real-time monitoring and management of energy consumption, and provide data support for reasonable deployment of energy and energy saving and emission reduction.

Maintenance and upkeep

Regularly check the appearance: check the appearance of the module every once in a while to see if there is any damage, deformation, corrosion, etc. If there is any problem, it should be replaced or repaired in time.

Clean the heat dissipation channels: Use compressed air or soft brushes to regularly clean the module's heat sinks and vents of dust and debris to prevent overheating of the module due to poor heat dissipation, which affects performance and life.

Backup Configuration Parameters: Regularly backup the configuration parameters and programs of the module in case of data loss or module failure to quickly restore the normal operation of the system.

Check the connection line: Regularly check whether the connection line of the module is loose, aging, broken, etc. If there is any problem, it should be replaced or repaired in time to ensure the reliability of the connection.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com