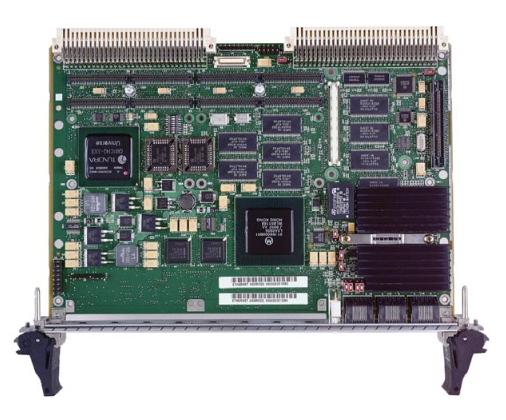

GE IS220UCSAH1AK - UCS CONTROLLER

Overview

Product Definition and Role: GE IS220UCSAH1AK - UCS CONTROLLER is a controller developed by General Electric (GE) that plays a central role in industrial automation and control systems. It is like the ‘brain’ of the system, responsible for coordinating and managing operations between various devices and subsystems, and achieving precise control of industrial processes by receiving input signals, executing control algorithms and outputting commands.

Working Principle

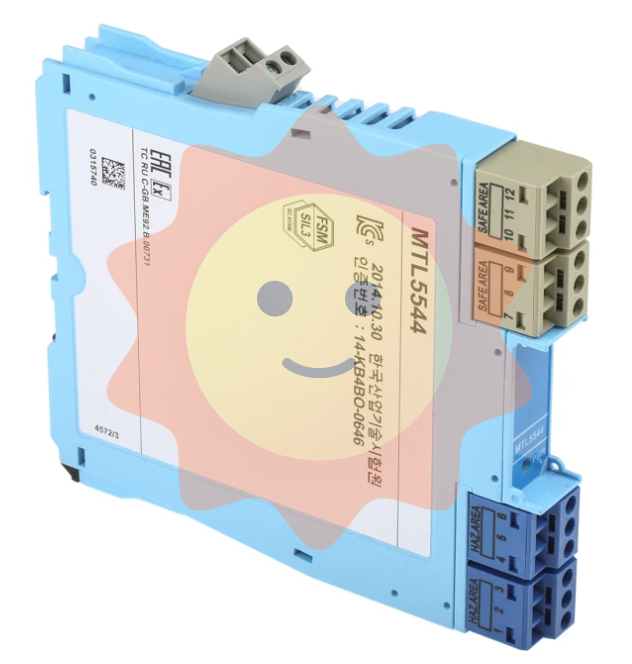

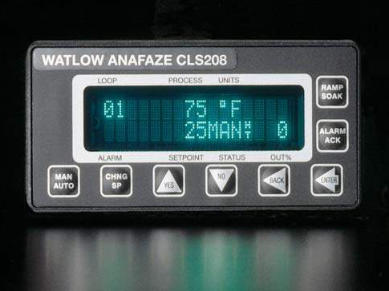

Signal Processing and Input: The controller has multiple input ports to receive signals from various sensors (e.g., temperature sensors, pressure sensors, flow sensors, etc.). These signals can be analogue (e.g. 4 - 20mA current signals, 0 - 10V voltage signals) or digital (e.g. switching signals). For analogue signals, the analogue-to-digital conversion (A/D) circuitry inside the controller converts them to digital signals for subsequent processing. The digital signals are then conditioned and buffered before being fed to the processor.

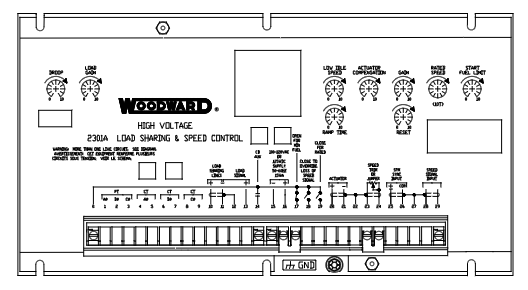

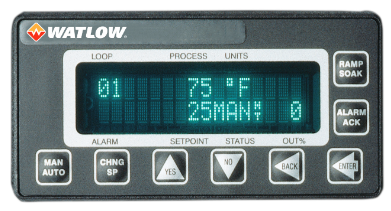

Control Algorithm Execution: Once the signal has been processed and converted to digital form, the controller performs operations based on pre-programmed control algorithms. These control algorithms can include proportional-integral-derivative (PID) control, logic control, fuzzy control, and many other types. For example, in PID control, the controller calculates the appropriate output control amount based on the deviation between the setpoint and the actual input value by adjusting the proportional, integral and differential parameters to achieve precise regulation of the industrial process.

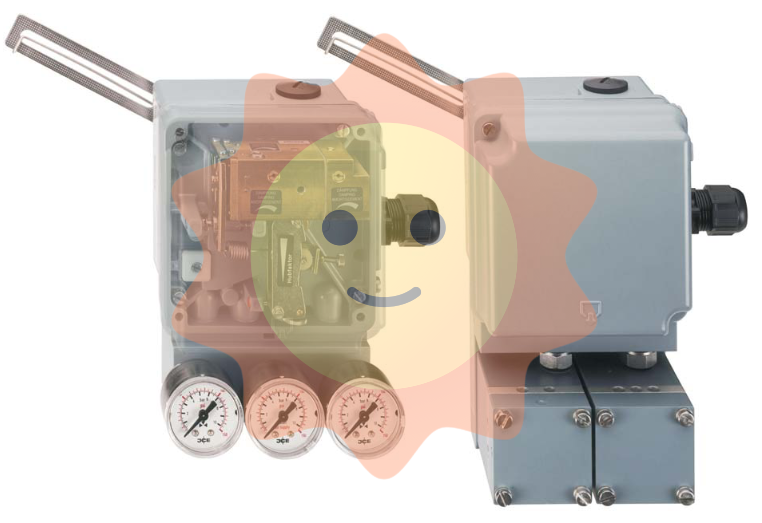

Command output and device control: The output commands calculated by the control algorithm are sent out through the output port of the controller. For analogue outputs (e.g. control of valve openings, motor speeds, etc.), the digital-to-analogue (D/A) circuitry converts the digital commands into analogue signals (e.g. 0 - 10V voltage signals or 4 - 20mA current signals). For the digital output, the controller will provide enough drive capability to control the state of external devices (e.g. relays, indicators, etc.), thus enabling control of the entire industrial process.

Performance features

Powerful control functions: with a variety of control algorithms and modes, it can adapt to the complex and changing industrial control needs. Both simple on/off control and complex continuous process control (e.g. chemical reaction process control, combined temperature-pressure control, etc.) can be programmed. This versatility allows it to be used in a wide range of industrial applications.

High processing power and speed: High-performance processors enable fast processing of large numbers of input signals and execution of complex control algorithms. With fast data processing speed, it can complete the whole process from signal input to instruction output in a short time, ensuring real-time control of industrial processes. For example, in high-speed automated production lines, it can respond to changes in the status of various equipment in a timely manner to ensure the efficient operation of the production line.

Reliability and Stability: Adopting industrial grade electronic components and advanced manufacturing process, it has high reliability and stability. It can run stably for a long time in harsh industrial environments, such as high temperature, high humidity, strong electromagnetic interference in the environment can still work normally. At the same time, may have fault diagnosis and fault tolerance, when part of the component failure, can automatically switch to standby mode or send an alarm signal to reduce system downtime.

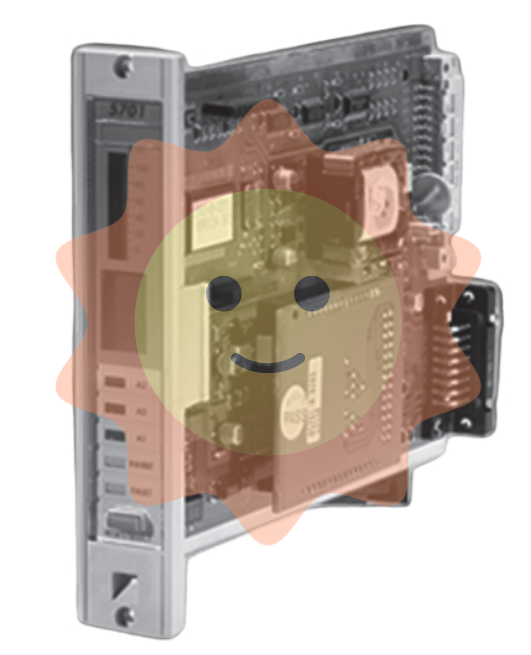

Communication capability and system integration: It has rich communication interfaces and supports a variety of industrial communication protocols (such as Ethernet/IP, Modbus, Profibus, etc.). This enables it to carry out convenient data communication and system integration with other devices (such as remote I/O modules, human-machine interface devices, upper computer monitoring system, etc.), and realise the collaborative work of the whole industrial control system.

Technical Parameters

Input parameters

Analogue input range: Usually it can receive common analogue signal ranges, such as voltage signals ranging from - 10V - + 10V, 0 - 10V, current signals ranging from 4 - 20mA, etc. The number of input channels may vary depending on the specific model. The number of input channels may vary depending on the specific model, typically there are multiple analogue input channels, each with a resolution of 12 - 16 bits to ensure accurate acquisition of analogue signals.

Digital Input Type: Supports a variety of digital signal level standards, such as TTL (Transistor - Transistor Logic) level, CMOS (Complementary Metal Oxide - Semiconductor) level, and is capable of handling a variety of switching signals, such as on/off signals of sensors, limit switch signals, and so on. The number of digital input channels is also high to meet different application requirements.

Output Parameters

Analogue output range: The analogue output range matches the input range, e.g. a voltage signal of 0 - 10V or a current signal of 4 - 20mA can be output, which can be used to control the working status of external devices. The output signals are of high precision and can meet the application scenarios that require high control precision. The number of output channels can be configured according to specific functional requirements, and generally there are multiple channels for controlling different devices.

Digital Output Characteristics: The digital output can provide sufficient driving capability, and the output current can reach tens of milliamps (mA) to ensure that it can reliably drive external digital devices (e.g., relays, indicator lights, etc.). The output signal levels conform to industry standards, such as 3.3V - 5V (TTL levels) for high levels and near 0V for low levels.

Processing power parameters

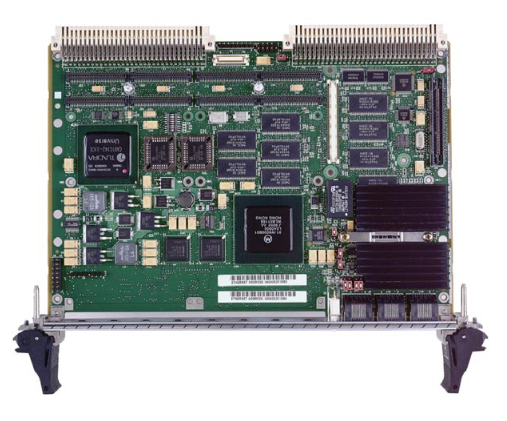

Processor Type and Frequency: A high performance processor is used, the processor type may be based on ARM architecture or other industrial grade processor chips with high operating frequency, e.g. up to a few hundred megahertz (MHz), to ensure fast data processing capability.

Memory capacity and type: Memory with a certain capacity, including random access memory (RAM) and flash memory (Flash), RAM capacity may range from several megabytes (MB) to tens of megabytes, for storing temporary data and running programs; Flash capacity is used for storing control programs, configuration parameters, etc., the capacity of which may range from several tens of megabytes to hundreds of megabytes, which is convenient for users to carry out program updates and parameter configuration. Flash capacity is used to store control programmes, configuration parameters, etc., which may range from tens of megabytes to hundreds of megabytes, which is convenient for users to carry out programme update and parameter configuration.

Communication Parameters

Supported communication protocols: It supports a variety of industrial communication protocols, such as Ethernet/IP for Ethernet communication, which can realise high-speed data transmission and remote monitoring; Modbus protocol is used for simple and reliable communication with a variety of devices; Profibus protocol is suitable for communicating with some European standard industrial devices, and so on.

Communication rate: In Ethernet communication, the communication rate can reach 10Mbps - 1000Mbps, depending on the network configuration; the communication rate of other communication protocols can also meet the real-time requirements of the industrial control system, for example, the communication rate of Modbus can reach 19.2kbps - 1Mbps.

Physical Parameters

Dimensions: The external dimensions are generally designed according to the installation requirements of the system, the length may be between 20 - 30cm, the width between 10 - 20cm, and the thickness between 3 - 8cm, which is easy to install in the control cabinet.

Weight: The weight is usually between 1 - 3kg, depending on the number and type of components inside.

Environmental parameters

Operating Temperature Range: Capable of operating over a wide range of temperatures, typically from - 20°C to + 60°C, some models may have a wider temperature range to suit different industrial site temperature conditions.

Humidity range: Relative humidity range is typically 10% - 90% (non-condensing) to ensure normal operation in different humidity environments.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com