RED670 is used for the protection, control and monitoring of overhead lines and cables in all types of networks. The IED can be used from distribution up to the highest voltage levels. It is suitable for the protection of heavily loaded lines and multi-terminal lines where the requirement for tripping is one-, two-, and/or three-phase. The IED is also suitable for protection of cable feeders to generator block transformers.

The phase segregated current differential protection provides an excellent sensitivity for high resistive faults and gives a secure phase selection. The availability of six stabilized current inputs per phase allows use on multi-breaker arrangements in three terminal applications or up to five terminal applications with single breaker arrangements.

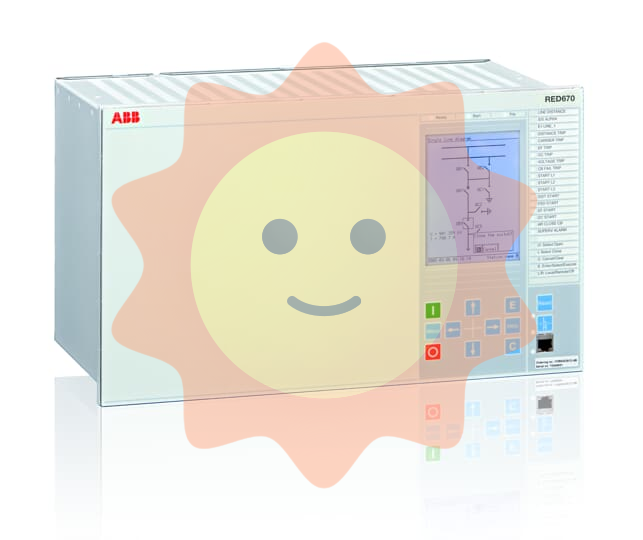

ABB RED670 Line differential protection

The phase segregated current differential protection provides an excellent sensitivity for high resistive faults and gives a secure phase selection. The availability of six stabilized current inputs per phase allows use on multi-breaker arrangements in three terminal applications or up to five terminal applications with single breaker arrangements.

The communication between the IEDs involved in the differential scheme is based on the IEEE C37.94 standard and can be duplicated for important installations when required for redundancy reasons. Charging current compensation allows high sensitivity also on long overhead lines and cables. A full scheme distance protection is included to provide independent protection in parallel with the differential scheme in case of a communication channel failure for the differential scheme.

The distance protection then provide protection for the entire line including the remote end back up capability either in case of a communications failure or via use of an independent communication channel to provide a fully redundant scheme of protection (that is a second main protection scheme). Eight channels for intertrip and other binary signals are available in the communication between the IEDs.

Core functions and advantages

1 Core protection functions

-Longitudinal differential main protection: As the main protection of the line, it adopts the principle of phase separated current differential and achieves real-time synchronization and comparison of current data at both ends of the line through optical fiber communication. When a fault occurs in the line area, the difference in current between the two ends significantly increases, and the device can quickly trip and cut off the fault within 10ms; When there is a fault outside the area, it is reliable not to operate, ensuring the selectivity and speed of protection, which is the core guarantee of high-voltage line protection.

-Perfect backup protection: Integrated with three-stage overcurrent protection, zero sequence current protection, overvoltage protection, low voltage protection and other backup protection functions. When the main protection exits due to communication faults or other reasons, the backup protection can operate according to the preset time limit based on the fault type and severity, forming a multi-level protection system to ensure reliable fault removal.

-Fault detection and identification: With the ability to identify phase faults, it can accurately distinguish different types of faults such as single-phase grounding, two-phase short circuit, and three-phase short circuit. At the same time, it supports fault distance measurement function. By analyzing the fault current and voltage signals, the distance to the fault point can be calculated, and the error can be controlled within 1%, providing accurate basis for fault repair.

-Recloser control: Built in adaptive reclosing function, which can intelligently determine whether to perform reclosing operation based on the nature of the fault (permanent fault/instantaneous fault). It supports single-phase reclosing, three-phase reclosing, and comprehensive reclosing modes, effectively improving the power supply continuity of the power system and reducing unplanned power outage time.

-Abnormal working condition monitoring and alarm: Real time monitoring of the device's own operating status (such as power failure, communication interruption, hardware abnormalities, etc.) and line operating parameters (such as overload, current imbalance, voltage fluctuations, etc.). When an abnormality is detected, an audible and visual alarm signal is immediately issued and relevant information is recorded for timely processing by operation and maintenance personnel.

2 Auxiliary functions

-Measurement and control function: With high-precision electricity measurement capability, it can real-time collect parameters such as current, voltage, power, and electrical energy of the line, support telemetry, remote signaling, remote control, and remote adjustment (four remote) functions, and meet the monitoring and control requirements of the substation automation system for the operation status of the line.

-Fault recording: Equipped with a large capacity fault recording module, it can record signals such as current, voltage, and switch status before, during, and after a fault. The recording length and triggering conditions can be flexibly configured, and the recording data can be exported through a USB interface or uploaded to the network, providing raw data for fault analysis and protection action evaluation.

-Communication function: Equipped with rich communication interfaces, including Ethernet interfaces (10/100/1000Mbps), RS485 interfaces, etc., supporting multiple international standard communication protocols such as IEC 61850, IEC 60870-5-103, Modbus, etc., it can achieve data exchange and information sharing with SCADA systems, background monitoring systems, and other protective devices.

-Fixed value management and logging: supports online query, modification, and solidification of protection fixed values, with fixed value area switching function to meet protection requirements under different operating modes; At the same time, it automatically records protection action logs, operation logs, alarm logs, etc. The log information can be stored for a long time and is not easily lost, making it easy to trace and determine responsibility during operation.

3 Product advantages

-Ultra high reliability: adopting dual hardware design and redundant configuration, key components (such as power supply, CPU, communication module) have self diagnostic function, and the mean time between failures (MTBF) exceeds 100000 hours; Certified according to multiple international standards such as IEC 61850-3, it can adapt to harsh operating environments such as high temperature, low temperature, humidity, and vibration.

-Fast action performance: Based on advanced digital signal processing algorithms, the action time of longitudinal differential protection can reach up to 5ms, far superior to traditional protection devices, which can effectively shorten the duration of faults and reduce the impact and damage of faults on power equipment.

-Flexible Scalability: Adopting modular design, it supports flexible configuration and upgrading of functional modules, and can add or expand protection functions, measurement and control functions, and communication interfaces according to actual engineering needs, reducing equipment upgrade costs and adapting to the development needs of the power system.

-Convenient operation and debugging: equipped with a graphical human-machine interaction interface (HMI), the operation is simple and intuitive; Support local debugging and remote operation and maintenance. Through dedicated software, functions such as protection setting configuration, fault recording analysis, and device status monitoring can be achieved, greatly improving operation and maintenance efficiency.

-Intelligent compatibility features: fully supports the IEC 61850 standard, with GOOSE (General Object Oriented Substation Events) and SV (Sampling Value) service capabilities, can directly access the process layer network of smart substations, achieve digital transmission and sharing of information, and conform to the development trend of smart grids.

Key technical parameters

parameter category

Specific parameters

Instructions

Model identification

RED670

ABB RELION ® Series line longitudinal differential protection special model

Applicable voltage level

110kV~1000kV

Covering the protection requirements of high voltage, ultra-high voltage, and extra high voltage transmission lines

Protection principle

Phase separated current longitudinal differential, three-stage overcurrent, zero sequence current protection, etc

Multi level protection configuration of primary protection and backup protection

Action Time

Longitudinal differential protection: ≤ 10ms; Backup protection: Flexible configuration (0.1-30s)

The main protection has excellent quick action performance, and the backup protection time limit meets the system's coordination requirements

Accuracy of current measurement

± 0.2% (within the rated current range)

High precision measurement ensures the accuracy of protection actions

Voltage measurement accuracy

± 0.2% (within the rated voltage range)

Meet the high-precision requirements of energy metering and protection control

Fault location accuracy

≤ 1% of the total length of the line

Provide precise positioning basis for fault repair

communication interface

2 Gigabit Ethernet interfaces; 2 RS485 interfaces; 1 USB interface

Support multiple communication methods to meet different networking needs

Support communication protocols

IEC 61850 (GOOSE/SV)、IEC 60870-5-103、Modbus RTU/TCP

Compatible with mainstream substation automation system communication standards

working power supply

DC: 220V/110V ± 20%; Communication: 220V ± 20% (optional); Power consumption: ≤ 50W

Wide voltage range adaptation to meet different substation power configurations

Environmental adaptation range

Working temperature: -25 ℃~+70 ℃; Relative humidity: 5%~95% (no condensation); Protection level: IP54 (device body)

Adapt to various installation environments such as substation control rooms and outdoor cabinets

Installation method

19 inch standard cabinet installation (4U height)

Complies with the standardized installation specifications for secondary equipment in substations

Applicable scenarios

The RED670 line longitudinal differential protection device is widely used in various high-voltage transmission line protection systems due to its excellent performance and flexible adaptability. Typical application scenarios include:

1. Backbone power grid transmission lines: In the 110kV~1000kV backbone transmission lines of State Grid and Southern Power Grid, as the main protection device, it quickly cuts off line faults, prevents faults from spreading to the entire power grid, ensures the safe and stable operation of the power grid, and avoids large-scale power outages.

2. Regional power grid interconnection line: In the interconnection lines between regional power grids, longitudinal differential protection is used to achieve coordinated action at both ends of the line, ensuring quick isolation in case of interconnection line faults. At the same time, its measurement and control functions are used to achieve real-time monitoring and adjustment of interconnection line power, ensuring the power balance of the regional power grid.

3. Power plant transmission lines: In the transmission lines of thermal power plants, hydropower plants, wind power plants, etc., the connection between the power plant and the power grid is protected for safety. When the line fails, it is quickly cut off to avoid the impact of the fault on the power plant's generator units, while ensuring the reliable transmission of power from the power plant to the power grid.

4. Intelligent Substation: In intelligent substations based on the IEC 61850 standard, the RED670 device seamlessly connects with process layer equipment (merging units, intelligent terminals) and station control layer systems through GOOSE/SV services, achieving digital transmission and sharing of protection information and supporting the automation and intelligent operation of intelligent substations.

5. Industrial enterprises' self owned power plant lines: In the connection lines between the self owned power plants of large industrial enterprises such as steel, chemical, metallurgical, etc. and the internal power grid of the enterprise, the stable transmission of electricity from the self owned power plants is guaranteed, while preventing internal faults from affecting the public power grid, achieving safe isolation between the enterprise power grid and the public power grid.

6. Cross regional power transmission projects: In cross regional long-distance power transmission projects such as West East Power Transmission and North South Power Supply, the RED670 device adapts to the protection needs of long-distance transmission lines with its fast action performance and accurate fault location function, ensuring the safety and reliability of cross regional power transmission.

Installation and usage precautions

1 Installation precautions

-Before installation, it is necessary to confirm that the device model, rated parameters, and engineering design requirements are consistent. Check that the appearance of the device is not damaged, the modules are not loose, the wiring terminals are not bent or deformed, and the accessories (such as installation rails, fixing screws, communication cables) are complete.

-The device should be installed in a 19 inch standard cabinet, which should have good ventilation and heat dissipation performance, avoiding direct sunlight, rainwater erosion, and dust accumulation; The installation location should be away from strong magnetic fields and interference sources (such as high-power transformers and frequency converters), and shielding measures should be taken if necessary.

-Before wiring, it is necessary to disconnect the working power supply and related secondary circuit power supply of the device, strictly follow the device wiring diagram for wiring, and separate the current circuit, voltage circuit, control circuit, and communication circuit to avoid cross interference; Open circuits are strictly prohibited in current circuits, and short circuits are strictly prohibited in voltage circuits.

-The connection of fiber optic communication lines should ensure that the interface is clean and the connection is firm. The bending radius of the fiber optic cable should be greater than 15 times the diameter of the fiber optic cable to avoid excessive bending and damage to the fiber optic cable; The communication line should use shielded cables, and the shielding layer should be reliably grounded to reduce electromagnetic interference.

-After installation, it is necessary to check whether the device is firmly fixed, whether the wiring terminals are tightened, and conduct insulation resistance testing (the insulation resistance of each circuit to ground should be ≥ 10M Ω). After confirmation, the power can be turned on.

2 Precautions for use

-Before the first power on, it is necessary to confirm that the working power supply voltage is consistent with the rated power supply voltage of the device, check the positive and negative wiring of the power supply to avoid reverse connection and damage to the power module; After powering on, observe whether the device starts normally and proceed with subsequent configuration only if there are no hardware fault alarms.

-The setting and modification of protection settings must be strictly carried out in accordance with the operating regulations of the power system. Before modification, the original settings must be backed up, and after modification, the settings must be checked and solidified to prevent protection misoperation or refusal due to incorrect settings; Under different operating modes, it is necessary to switch to the corresponding fixed value area.

-Regularly inspect the device, check the status of the device indicator lights, whether the display screen information is normal, and whether there are any abnormal alarm signals; Check whether the wiring terminals are loose or overheating, and whether the fiber optic interface is contaminated with dust. Clean and tighten them in a timely manner.

-After a fault occurs, it is necessary to promptly export the fault recording data and protection action log for fault analysis, clarify the cause of the fault and the protection action situation; After the fault handling is completed, the device alarm signal needs to be reset to restore normal operation.

-The software upgrade of the device must be operated by authorized technical personnel from ABB. Before the upgrade, the device configuration file and historical data must be backed up. Power off is strictly prohibited during the upgrade process to avoid device failure caused by upgrade failure; After the upgrade, functional testing is required to ensure the normal performance of the device.

-Establish a comprehensive device operation file, recording device installation time, fixed value modification records, fault handling records, inspection records, and maintenance records, etc., to provide a basis for device lifecycle management; Unauthorized personnel are strictly prohibited from operating the device or modifying related configurations.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-