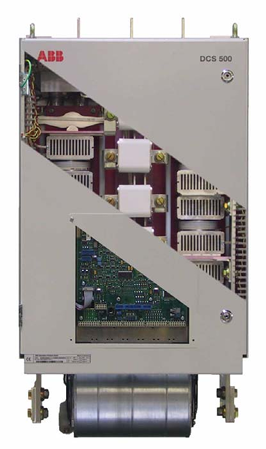

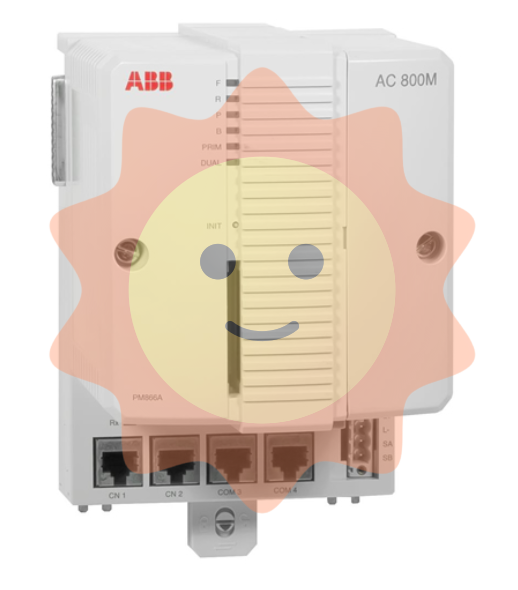

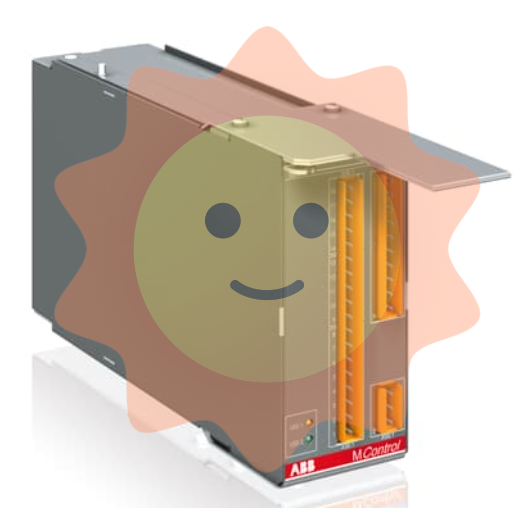

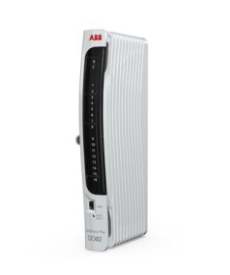

ABB SR511 3BSE000863R1 Redundant 5V Regulator

ABB SR511 3BSE000863R1 Redundant 5V Regulator

Product Overview

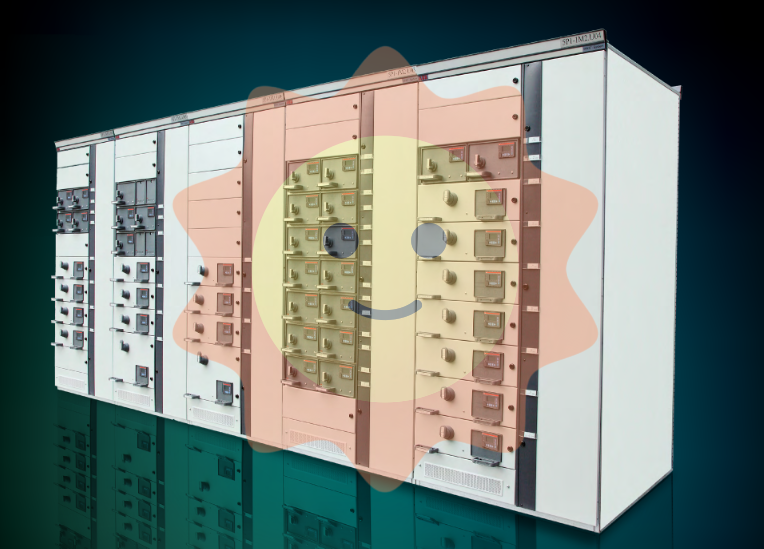

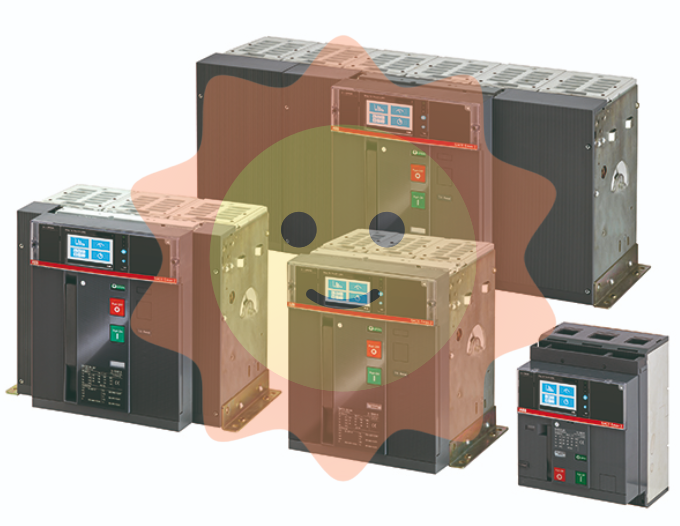

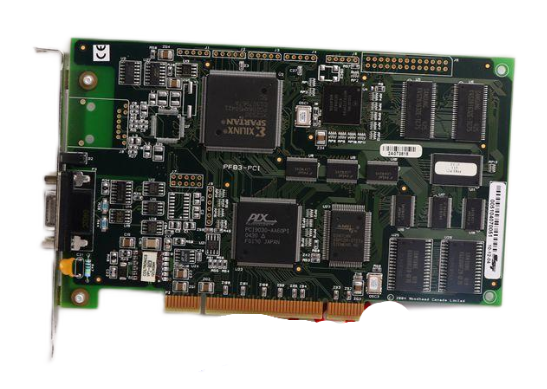

The ABB SR511 3BSE000863R1 is a redundant 5V voltage regulator designed for industrial automation applications that provides a stable 5V output voltage with redundancy features to ensure continuous system operation in the event of a single failure. The regulator is widely used in a variety of industrial automation systems that require a stable power supply and a high degree of reliability.

Key Features

Redundant design:

Adopting redundant design, when the main regulator fails, the backup regulator can immediately take over the work to ensure the stable supply of system power.

High-performance voltage regulator:

Provides accurate 5V output voltage with low noise and low ripple characteristics to meet the high requirements of industrial automation systems for power quality.

Wide input voltage range:

Able to accept a wide input voltage range, adapting to the power input requirements under different working conditions.

High reliability:

Manufactured with high-quality materials and advanced production process, after strict testing and screening to ensure the long-term stable operation of the product.

Easy integration:

Modular design, easy to integrate with other industrial automation components, simplifying the system design and installation process.

Technical Specifications

Model No.: SR511 3BSE000863R1

Output Voltage: 5V (redundant)

Input voltage range: depending on specific model and configuration (usually wider)

Operating temperature range: -20°C to +60°C (or different depending on specific model)

Dimensions: Model and configuration-specific (typically conforms to standard industrial automation component dimensions)

Weight: depending on the specific model and configuration (usually lightweight for ease of installation and transport)

Areas of application

The ABB SR511 3BSE000863R1 redundant 5V voltage regulator is widely used in a variety of industrial automation systems, including but not limited to:

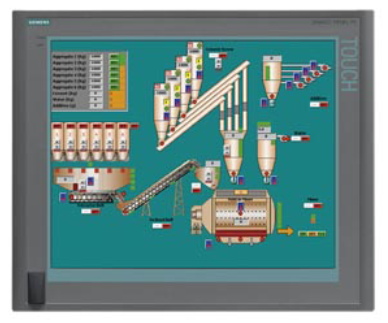

Manufacturing industry: used in equipment control, production line automation and other scenarios to improve production efficiency and quality.

Energy industry: used for equipment monitoring and management in power plants, substations and other places to ensure the stability and safety of power supply.

Transportation: Used in scenes such as rail transit and intelligent transport systems to ensure the normal operation and safety of the transport system.

Building automation: to achieve centralised control and monitoring of air-conditioning, lighting, security and other systems, to improve the intelligent level of building management.

Product Parameters and Specifications

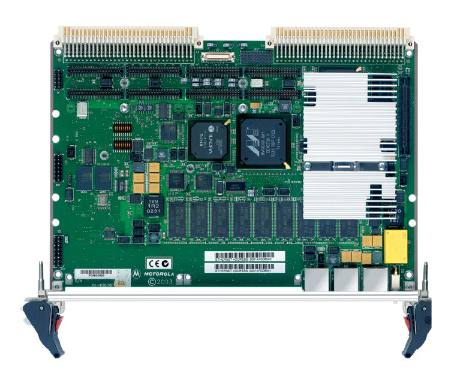

Processor: 32-bit RISC processor

Clock frequency: 100 MHz

Memory: 128MB

Flash memory: 256MB

Communication interface: RS-232/485, Ethernet, etc.

Input/output interface: analogue input/output, digital input/output

Operating temperature: -25°C to +60°C

Storage temperature: -40°C to +85°C

Relative humidity: 5% to 95% (non-condensing)

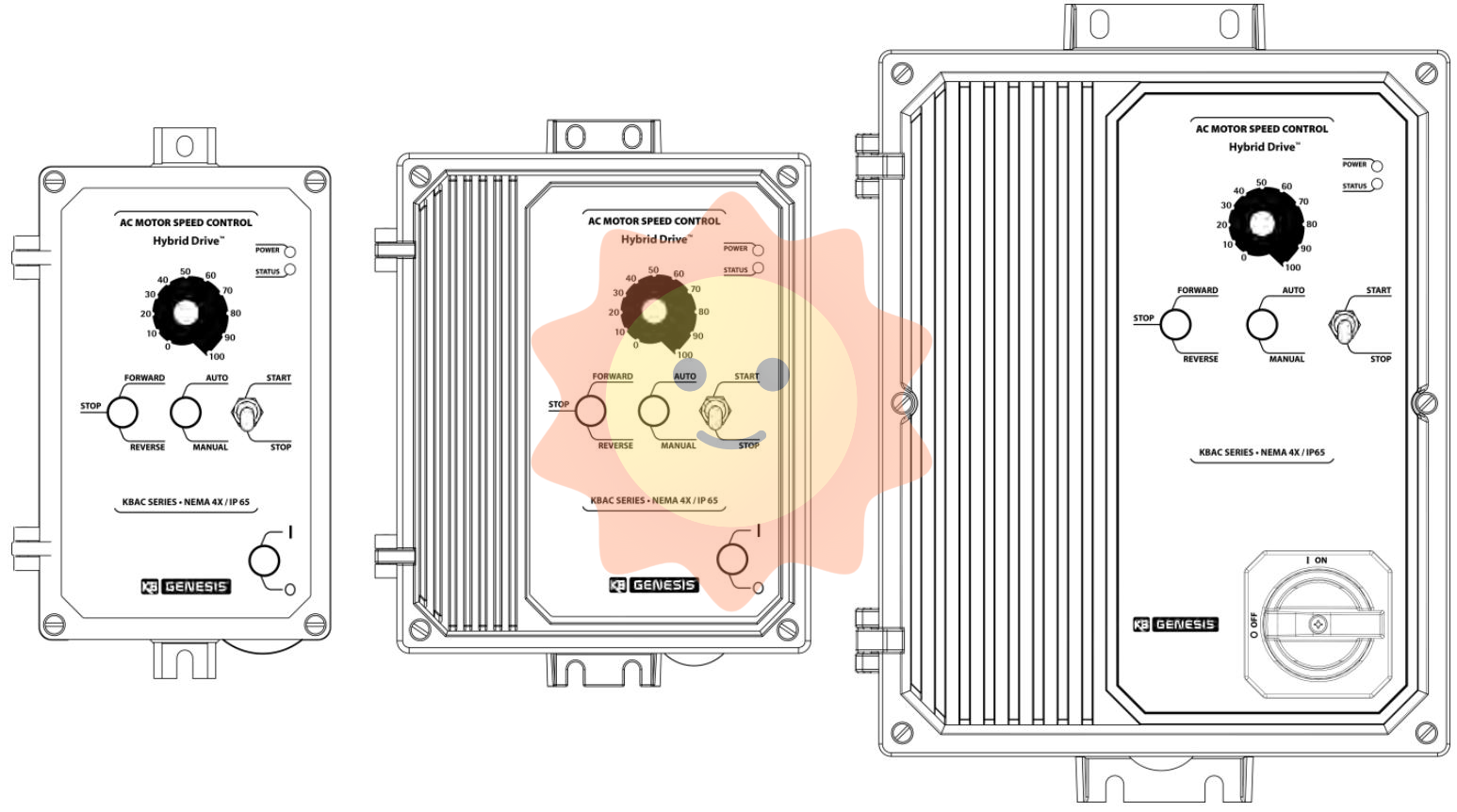

Protection rating: IP65

Product specification: 300mm x 200mm x 100mm

Installation and Maintenance

Environmental conditions:

Ensure that the module is installed within the recommended temperature and humidity ranges and avoid direct exposure to water, oil, dust or electromagnetic interference.

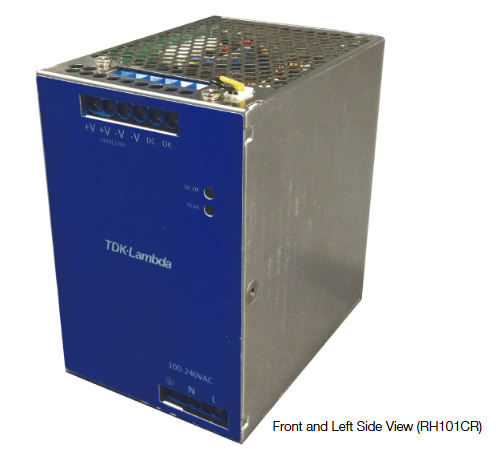

Power Requirements:

Use a stable power supply to avoid damage to the module from voltage fluctuations.

Signal Cable Connection:

Connect the signal lines correctly to ensure the accuracy and stability of signal transmission.

Software Configuration:

Correctly configure the software parameters of the module according to the system requirements to ensure compatibility with other parts of the control system.

Maintenance and Inspection:

Perform regular maintenance and inspection of the module, including cleaning and checking the contact status of the connectors.

Precautions

Operator Training:

Operators should receive proper operation and maintenance training to avoid malfunctions or safety accidents caused by incorrect operation.

Technical Documentation and Safety Guidelines:

The technical documentation and safety guidelines provided by the manufacturer should be read and understood in detail before installation and use.

Compliance with safety regulations:

Observe all relevant safety procedures to ensure personal safety, especially when handling high-pressure or high-speed rotating equipment.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-

Email:wang@kongjiangauto.com