ABB GJR5252300R3101 07AC91F is a high-performance industrial control module compatible with ABB AC 800M series PLC, originating from Switzerland. Its core function is to serve as a "distributed control node" for medium to large-scale industrial automation systems, undertaking complex signal acquisition, high-precision process control, and multi device collaborative scheduling tasks. It can seamlessly link with AC 800M series core controllers (such as PM866), while supporting redundant design and multi protocol communication. It is widely used in key industrial scenarios such as power, chemical, and metallurgical industries that require high control accuracy and system reliability. It is a core component to ensure stable and efficient operation of large-scale production processes.

ABB GJR5252300R3101 07AC91F Industrial Control Module

Core positioning and basic information

ABB GJR5252300R3101 07AC91F is a high-performance industrial control module compatible with ABB AC 800M series PLC, originating from Switzerland. Its core function is to serve as a "distributed control node" for medium to large-scale industrial automation systems, undertaking complex signal acquisition, high-precision process control, and multi device collaborative scheduling tasks. It can seamlessly link with AC 800M series core controllers (such as PM866), while supporting redundant design and multi protocol communication. It is widely used in key industrial scenarios such as power, chemical, and metallurgical industries that require high control accuracy and system reliability. It is a core component to ensure stable and efficient operation of large-scale production processes.

Key technical specifications

Core functions

Multi channel high-precision I/O control+complex logic/process control+redundant collaboration

Integrate signal acquisition, operation control, and redundant synchronization functions to meet the distributed control requirements of medium to large systems and reduce the load on core controllers

Input/output channel configuration

Analog input (AI): 16 channels (supporting 4-20mA DC, 0-10V DC, thermocouple, thermistor, accuracy ± 0.05% FSO); Analog output (AO): 8 channels (4-20mA DC/0-10V DC, accuracy ± 0.1% FSO); Digital input (DI): 32 channels (24VDC dry/wet contacts, supporting edge detection and filtering); Digital output (DO): 16 channels (24VDC transistor output, maximum load 1A/channel, supports PWM control)

The number and accuracy of channels are suitable for medium to large-scale scenarios, covering high-precision monitoring of multiple parameters such as temperature, pressure, and flow rate, meeting the driving requirements of complex actuators such as frequency converters and regulating valves

Control algorithm support

Built in multi loop PID control (including cascade, ratio, feedforward control), advanced logic control (LD/FBD/ST compatible), sequential control (SFC with branch and parallel functions), model predictive control (MPC) basic functions

Support the development of complex industrial process control logic, such as multi parameter coupling adjustment of chemical reaction vessels and synchronous control of metallurgical rolling mills, without relying on external algorithm modules

Communication and redundancy capability

Communication interfaces: 2 Gigabit Ethernet interfaces (supporting PROFINET IRT and EtherNet/IP), 1 Profibus DP master station interface, and 1 CANopen interface; Redundancy support: Controller redundancy (1:1 hot standby, switching time ≤ 50ms), communication redundancy (dual Ethernet ring network), power redundancy (dual 24VDC input)

High speed communication and fully redundant design ensure real-time data transmission (Ethernet latency ≤ 1ms) and operational continuity for medium to large systems, avoiding production interruptions caused by single point failures

Data Processing and Storage

Processor: Dual core 800MHz industrial grade processor; Memory: 512MB DDR3 RAM (running memory)+4GB Flash (storage memory, supports historical data caching and program backup)

Powerful data processing and storage capabilities, capable of handling over 1000 real-time data points locally, with short-term caching of critical production data (such as 72 hour trend data) to prevent data loss in case of communication interruption

Working power supply

24VDC ± 15% (dual power redundant input, maximum power consumption of 15W)

Wide voltage input adapts to power supply fluctuations in industrial sites, dual power independent power supply ensures normal module operation in the event of a single power failure, and adapts to power supply requirements in critical production scenarios

Working temperature range

-40 ℃ to+70 ℃

Strong adaptability to extreme environments, capable of stable operation in outdoor power facilities, high-temperature metallurgical workshops, low-temperature chemical storage tank areas, and other scenarios without the need for additional temperature control equipment

Protection level

IP20 (module body), optional IP65 explosion-proof enclosure (for on-site installation in hazardous environments)

The standard configuration is suitable for installation inside the control cabinet, and the optional explosion-proof shell meets the requirements of special scenarios such as chemical explosion-proof zones (such as Zone 2) and dust explosion-proof zones

Protection and diagnostic functions

Overvoltage/overcurrent protection: analog terminal 30V DC transient overvoltage protection, digital terminal 2A self recovery fuse; Fault diagnosis: supports intelligent diagnosis of channel faults (disconnection/over range), communication faults, and hardware faults, with diagnostic information in accordance with NAMUR NE 107, and supports remote fault reset

Multiple protection mechanisms prevent module damage caused by on-site equipment failures, intelligent diagnostic functions shorten troubleshooting time, and reduce maintenance costs for medium and large-scale systems

Typical application areas

Chemical industry (large petrochemical facilities)

In large-scale petrochemical plants such as ethylene synthesis and PX production, modules serve as distributed control nodes to collect key parameters such as reactor temperature (thermocouple, accuracy ± 0.1 ℃), raw material feed flow rate (4-20mA), and distillation tower pressure (0-10V). Through multi loop PID cascade control, the opening of the feed valve and heating power are adjusted, while redundantly linked with the AC 800M core controller. When a module fails, the redundant unit switches seamlessly to ensure 24/7 continuous production and avoid safety risks such as explosion and leakage caused by control interruption.

Power industry (large thermal power plants)

In the boiler feedwater system and desulfurization and denitrification system of thermal power plants, modules control dozens of equipment such as feedwater pumps, induced draft fans, and denitrification spray guns, collecting parameters such as feedwater pressure (4-20mA), flue gas NOx concentration (4-20mA), fan current (DI signal), etc., and implementing equipment start stop sequence control through logical interlocking (such as pre blowing of fans before boiler ignition). Real time communication with the power plant DCS system is achieved through PROFINET IRT protocol (delay ≤ 1ms), receiving dispatch instructions to adjust equipment load, ensuring stable operation of the generator set and environmental compliance.

Metallurgical industry (large steel joint venture)

In the hot rolling production line of the steel plant, the module is responsible for controlling the rolling mill gap, adjusting the strip tension, collecting parameters such as roll pressure (4-20mA), strip speed (pulse signal), and roll temperature (thermal resistance), and predicting the strip thickness deviation in advance through model predictive control (MPC). The hydraulic cylinder pressure (AO output) is adjusted in real time to ensure that the strip thickness deviation is controlled within ± 0.05mm. Simultaneously supporting high-speed communication with the rolling mill drive system (frequency converter), achieving synchronous operation of the rolling mill and conveyor belt, and improving product quality and production efficiency.

Water treatment industry (large sewage treatment plants)

In the aeration tank and sludge dewatering system of large urban sewage treatment plants, the module collects parameters such as dissolved oxygen concentration (4-20mA, accuracy ± 0.05mg/L), sludge concentration (4-20mA), and dewatering machine speed (DI signal) in the aeration tank. PID control is used to adjust the speed of the aeration fan and the amount of sludge added, and sequential control is used to achieve automation of the sludge dewatering process (such as feeding pressing discharging). Redundant communication design ensures stable data exchange with the SCADA system of the sewage treatment plant, avoiding substandard effluent quality caused by communication interruptions.

Key points of installation and operation and maintenance

(1) Installation specifications

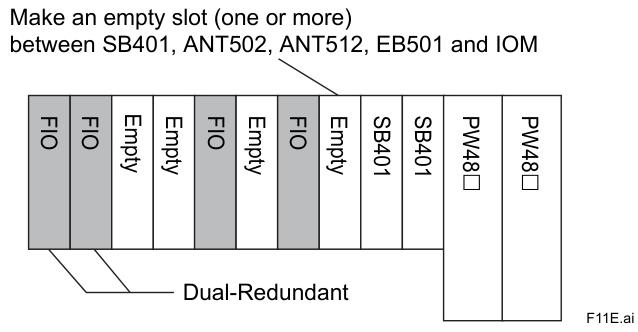

Installation inside the control cabinet: Suitable for standard 19 inch industrial control cabinets, it needs to be installed on the same backplane as the AC 800M core controller (distance ≤ 2m) to ensure stable transmission of redundant synchronous signals; Reserve a heat dissipation space of ≥ 10cm around the module to avoid being too close to strong electromagnetic equipment such as frequency converters and high-power transformers (recommended ≥ 50cm), in order to prevent electromagnetic interference from affecting signal acquisition accuracy.

On site explosion-proof installation (with IP65 enclosure): It needs to be installed in an explosion-proof junction box, with a grounding resistance of ≤ 1 Ω for the enclosure. The cable is connected through an explosion-proof gland (compatible with 8-16mm cables) to avoid spark leakage; The installation location should be kept away from flammable medium pipelines (distance ≥ 1m) to prevent leakage of medium from corroding the module.

Wiring operation:

Signal wiring: Analog signal lines (especially thermocouples and resistance wires) use shielded twisted pair wires (cross-sectional area 0.5-1mm ²), and the shielding layer is grounded at one end (grounding resistance ≤ 1 Ω); When connecting the digital output terminal to a high-power actuator (such as a frequency converter), a surge protector (2kV) should be connected in series to prevent voltage spikes caused by switch actions from damaging the module.

Power wiring: Connect the dual power sources to different UPS power sources to ensure power independence; Connect the power terminal in series with a 5A fuse (additional protection), with the positive terminal connected to "+V1/+V2" and the negative terminal connected to "- V1/- V2". Reverse connection is strictly prohibited.

Communication wiring: Gigabit Ethernet uses CAT6 shielded Ethernet cables to construct redundant ring networks (such as ABB Ring Protection), with a maximum of 32 ring network nodes; When connecting remote devices through the Profibus DP interface, 120 Ω terminal resistors are installed at both ends of the bus, and the communication distance is ≤ 1200m (without relays).

(2) Debugging and Calibration

System integration debugging: Complete module hardware configuration (channel signal type, range, redundant parameters) and control program download through ABB Control Builder M software, perform "redundant synchronization initialization", confirm the data synchronization status between the module and the core controller (software displays "Sync OK"); Test redundancy switching function: Disconnect the power supply of the main module, observe whether the backup module takes over control within 50ms, and ensure that there is no fluctuation in the operating parameters of the on-site equipment (such as valve opening and motor speed).

Channel accuracy calibration:

Analog input: Use a high-precision signal generator (accuracy ± 0.01%) to input 0%, 25%, 50%, 75%, and 100% full-scale signals to the AI terminal. Read the collected values through software, and the deviation should be ≤ ± 0.05% FSO. When the deviation is exceeded, perform multi-point linear calibration through software.

Analog output: Set the AO output to 4mA, 8mA, 12mA, 16mA, and 20mA signals, use a high-precision ammeter (accuracy ± 0.01%) to measure the output current, and the deviation should be ≤ ± 0.1% FSO to ensure the accuracy of the actuator action.

Control logic testing: Simulate process abnormalities (such as reactor temperature exceeding the set value by 5 ℃), check whether the module triggers PID adjustment actions (such as reduced heating power) and interlock protection (such as emergency relief valve opening); Test the sequence control process to confirm that the equipment start stop delay and conditional branch execution meet the design requirements (stop feeding if the liquid level is below the lower limit).

(3) Maintenance strategy

Daily maintenance (weekly):

Status monitoring: Check the module operating parameters (CPU usage, memory usage, communication packet loss rate) through the upper computer monitoring software to ensure that the CPU usage rate is ≤ 70% and the communication packet loss rate is ≤ 0.01%; Check the module indicator lights (power light PWR always on, redundancy light RED green light always on, fault light ALM off).

Signal inspection: Randomly select 10% analog channels, compare the collected values with the displayed values on the field instruments, and the deviation should be ≤± 0.1%. If it exceeds the tolerance, check the wiring and sensor status.

Regular maintenance (monthly):

Cleaning and fastening: Use dry compressed air (pressure ≤ 0.2MPa) to clean the dust on the surface of the module and between the terminals; Check if the wiring terminal screws are loose and tighten them again (M3 screw tightening torque 0.8-1.0N · m); Check if the shielding layer of the redundant communication cable is properly grounded.

Data backup: Backup module control programs, configuration files, and historical data to encrypted servers and offline hard drives to prevent data loss.

Annual maintenance:

Performance testing: testing module redundancy switching time (measured by oscilloscope, required to be ≤ 50ms), communication delay (measured by network analyzer, Ethernet delay ≤ 1ms), and analog channel accuracy recalibration; Check for any bulges in the module capacitor and ensure that the cooling fan (if any) is running properly. If necessary, replace any aging components.

System optimization: Adjust PID parameters (such as proportional coefficients and integration time) according to changes in production processes, optimize control logic, and improve control accuracy and system stability.

Fault handling:

Power failure: If both power lights are not on, check the UPS power output and fuse, eliminate the power supply problem, and if the problem persists, replace the module power module.

Communication failure: If Ethernet communication is interrupted, check the status of the ring network switch, the polarity of communication cables A/B, use serial debugging tools to test the communication link, and eliminate protocol mismatch issues.

Channel failure: If a certain AI channel has no collected values, first check the on-site sensors and wiring (whether there is a disconnection or short circuit), and then use a multimeter to measure the input signal of the terminal. If the signal is normal but the module does not collect data, the faulty channel needs to be disabled and the backup channel needs to be enabled (parameters need to be reconfigured), and the faulty module needs to be returned to the factory for repair.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-