DANAHER MOTION 522S65URL6000/522S65URL6000 linear guide rail

Automated production line: applied to the material handling, assembly and other processes of automated production lines. For example, on an electronic product assembly line, linear guides can drive robotic arms to move quickly and accurately between different workstations, achieving automatic grabbing, placement, and welding of electronic components, improving production efficiency and product quality stability; On the automotive parts production line, it is used for motion guidance of conveyor lines and assembly equipment to ensure accurate transportation and assembly of parts.

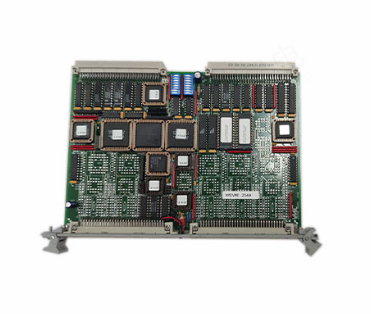

Semiconductor manufacturing equipment: In the process of semiconductor chip manufacturing, high precision and stability are required for the equipment. DANAHER MOTION 522S65URL6000/522S65URL6000 linear guides can be applied in equipment such as lithography machines and etching machines, providing precise linear motion guidance for wafer transport and positioning, ensuring the accuracy and reliability of chip manufacturing processes, and promoting the development of the semiconductor industry.

Medical devices: play an important role in medical equipment such as CT scanners and surgical robots. In CT scanners, linear guides are used to control the precise movement of the scanning bed, ensuring that patients can be accurately positioned at designated locations during the scanning process and obtaining clear and accurate imaging data; In surgical robots, stable guidance is provided for the movement of the robotic arm, enabling precise surgical operations and improving surgical safety and success rates.

Installation and maintenance precautions

Installation precautions

Before installation, it is necessary to ensure that the installation surface is clean, flat, free of oil stains, impurities, and protrusions to avoid affecting the installation accuracy and operational performance of the linear guide rail. Use professional measuring tools to inspect the installation surface to ensure that its flatness and straightness meet the requirements.

According to the requirements of the product manual, use appropriate installation tools and methods for installation. During the installation process, pay attention to the installation direction of the guide rail and slider to ensure correctness. At the same time, tighten the installation screws evenly to avoid deformation of the guide rail or jamming of the slider due to uneven force.

After installation, perform necessary debugging and inspection. Check whether the slider slides smoothly on the guide rail and whether there is any jamming phenomenon; Check if the accuracy of the linear guide meets the requirements, and adjust it promptly if there is any deviation.

Maintenance precautions

Regularly clean the linear guide rail to remove impurities such as dust, oil, and metal debris from the surface, preventing them from entering the interior of the guide rail and slider and exacerbating wear. When cleaning, a clean soft cloth or specialized cleaning agent can be used for wiping.

Lubricate the linear guide according to the prescribed cycle, using appropriate lubricants such as lithium based grease or lubricating oil. When lubricating, ensure that the lubricant is evenly applied to the contact surface between the guide rail and the slider to reduce friction and wear, and extend the service life of the linear guide rail.

Regularly check the accuracy and operating condition of the linear guide, observe whether the movement of the slider is smooth, and whether there are any abnormal noises or vibrations. If any problems are found, they should be repaired or replaced in a timely manner to avoid the problem from escalating and affecting the normal operation of the equipment.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

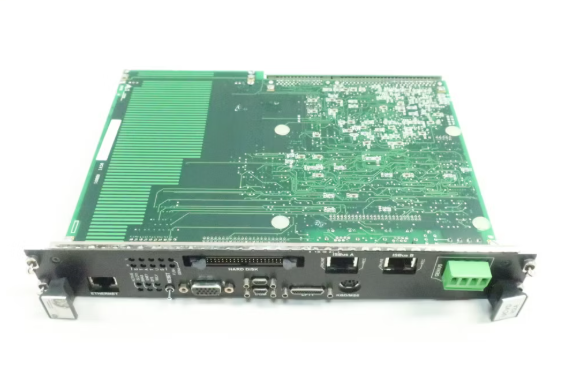

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com