"14th Five-Year Plan" development hotspot

During the "Fourteenth Five-Year Plan" period, what kind of development situation is China's chemical fiber industry facing, what are the key areas of development, and what aspects do enterprises need to focus on?

Duan Xiaoping pointed out that the "14th Five-Year Plan" is a key period from building a well-off society in an all-round way to basically realizing socialist modernization, and the industry will face major opportunities and major challenges, and the new coronavirus epidemic, industrial safety, scientific and technological innovation, green and low-carbon, "double cycle", and consumption upgrading will run through the development of the industry. "Double carbon", intelligence, differentiation, high performance and degradable fiber, new industrial structure and original innovation will become the key words of its development. On this basis, Duan Xiaoping analyzed the global development trend of chemical fiber: in 2020, the low base superimposed weak recovery, as a rigid demand, the global fiber will still grow at a rate of about 3%; Energy saving and emission reduction, recycling and degradable fibers will become the focus of the technological progress of bulk products in the chemical fiber industry, and the new entrants in the industry will decrease significantly, and the global competition pattern and production capacity distribution will become stable. With the technological progress and demand growth of wind power, photovoltaic and transportation industries, high-performance fibers represented by carbon fiber will open the gold mode, the industry's technological progress will accelerate, and the competitive landscape will undergo great changes; With the strengthening of the strength of large enterprises, the increase of investment in research and development, coupled with the complete industrial chain supporting advantages, China will achieve certain advantages in practical technological progress.

In addition, in the context of "dual carbon", Duan Xiaoping called on the chemical fiber industry should improve self-confidence, chemical fiber will still be a solid guarantee for the realization of the safety and reliability of the textile industry chain supply chain, will still be an indispensable cornerstone to meet the people's better life. He Yanli said that the fiber material at the source of the textile industry chain is very key, and its development is related to the green and high-quality development of downstream fabrics, printing and dyeing, and clothing. China is a large and powerful chemical fiber country, chemical fiber accounted for the proportion of China's textile fiber processing volume has reached 84%, in addition to clothing, home textile, in aerospace, national defense military industry, energy, transportation, civil engineering, Marine engineering, medical health and many other fields also have a large number of applications, in our national economy and social development occupies an important position. Therefore, the high-quality development of the chemical fiber industry during the "14th Five-Year Plan" requires the market and the government to jointly play the role of macro-control; The chemical fiber industry should vigorously promote new technologies of energy saving and emission reduction, and actively promote circular economy, especially pay attention to the recycling and reuse of waste textiles, break through relevant key technologies, and research and establish a standard system of regulations and policies for the recycling and reuse of waste textiles. At the same time, actively promote the chemical fiber industry green fiber certification and green fiber products certification.

Hua Shan said that science and technology, fashion, green is an important focus of the textile industry "fourteen five" development, the chemical fiber industry is the same. The "Fourteenth Five-Year Plan" development of the chemical fiber industry should be transformed from the past to the leading stage, and enterprises need to make a variety of reserves, and do a good job in capital, technology, equipment and other capacity building. In the "leading" stage, higher requirements are put forward for the innovation ability of enterprises, and enterprises also need to pay more attention to the innovation ability of the whole industrial chain, and pay more attention to and meet the needs of consumers.

Wang Songlin, executive vice president of Hengyi Petrochemical Co., Ltd. and president of Hengyi Research Institute, said that under the background of "double carbon", low-carbon, green and science and technology will run through. Enterprises to achieve low-carbon development, need to carry out more innovation from the aspects of energy conservation, further reduce emissions, green enterprises to think about whether they can develop environmentally friendly polyester products, such as Hengyi Group's current use of "antimony-free" catalyst. Scientific and technological innovation is the means to achieve low-carbon and green, during the "14th Five-Year Plan" period, Hengyi Group will increase investment in research and development in this regard, dare to enter the research and development "no man's land", and make some "pathfinder" contributions to the development of the industry.

To discuss the development trend of global chemical fiber industry

Affected by the epidemic, foreign industry representatives have been unable to come to the site to participate in the China International Chemical Fiber Conference for two consecutive years, but their concern for the conference and sharing information with the industry and thinking about the development of the industry is still strong.

Frederic Van Houte, President of the European Man-made Fiber Association, Ikuo Takeuchi, President of the Chemical Fiber Association of Japan, Kim Guok-jin, President of the Korean Chemical Fiber Association, S.C.Kapur, Secretary General of the Synthetic Fiber Industry Association of India, Mayuree, Honorary President of the Artificial Fiber Industry Association of Thailand Didpakdeechol, Su Baihuang, chairman of the artificial fiber manufacturing industry Trade Union in Taiwan, China, and other videos were recorded again to send blessings and support to the conference. They all mentioned that the world has become highly globalized and interdependent. The epidemic is still continuing, but with the gradual recovery of the economy, the further popularization of vaccines, and the innovation of process technology and digital empowerment to respond to changes in demand, the chemical fiber industry in various countries is getting out of the predicament to varying degrees. Based on digitalization, supply chain, carbon neutrality, fashion demand, etc., the global chemical fiber industry needs to work together, carry out more cooperation in more areas, take up the mission of implementing a circular economy, prepare for future sustainable development, and make the world a better place.

At the meeting, Fuyoshi Kenichi, executive vice president of the Chemical Fiber Association of Japan, introduced Japan's "sustainable development" series of actions, released the 2020 circular economy vision and plastic resource recycling strategy, and announced the goal of achieving "carbon neutrality" by 2050; Released reports such as "Future plastic Resource Recycling Measures", "Fashion and Environment Working Group", "Textile Industry Sustainable Development Research Group" and "Bioplastics Implementation Route"; Promulgation of the Plastic Resource Recycling Promotion Law. At the same time, the Japan Chemical Fiber Association has also formulated the industry sustainable development strategy - 2025 the Japan Chemical Fiber Association medium-term action Policy, and released the report of the Japan Chemical Fiber Association "Sustainable Development Working Group" in July 2021. The report prioritises PET recycling systems, fiber-to-fibre recycling systems, bio-based chemical fibres and tackling microplastics. He said that the Japanese textile and chemical fiber industry will always focus on sustainable development issues, and look forward to jointly exploring and practicing with the Chinese chemical fiber industry.

Frederic Van Houte, Director general of the European Man-made Fibers Association, said that the COVID-19 pandemic has had a serious impact on the supply chain of the European chemical fiber industry, but Europe has maintained its uniqueness in the field of chemical fiber. Facing the new international environment and development trend, the European chemical fiber industry has been laid out in the aspects of sustainable development, digital technology, cost effectiveness, quality and specialization, continuous innovation, fair competition and so on. For example, it has made the "dual transformation" as its main goal, aiming to make the entire economy green and digital; Building recycling centres and introducing a mandatory textile collection mechanism by 2025; Implement the "Carbon 55" plan to reduce greenhouse gas emissions by 55 percent by 2030; Implementing the European Zero Pollution Initiative and adopting a more stringent chemical policy; Improve production techniques, focus on the most efficient equipment, shut down or transform less efficient production lines; Increasing the use of certified renewable or recycled chemical fibers; Maintain diversification, small series, short-term delivery and other advantages, and enhance competitiveness in high value-added fibers.

Wang Jun, president of Oerlikon China

Georg Stausberg, CEO of Oerlikon Polymer Processing Solutions, and Jun Wang, President of Oerlikon China, introduced Oerlikon Group's value proposition for environmental and social governance (ESG) in an online and offline way, which enables customers to achieve higher output with fewer resources. Oerlikon's technology solutions are used to produce more than 35 million tons of chemical fibers annually, and its "Industry 4.0" factory solutions for filament spinning, elastic, staple and nonwovens are trusted by customers. In the future, the textile recycling and recycling amount of the entire industry and the corresponding manufacturing chain will be greatly improved, green textile production, chemical recycling and recycling, and textile intelligent manufacturing and equipment will gradually become the reality of the industry. Georg Stausberg revealed that Oerlikon can provide a variety of polyester-to-polyester physical recycling solutions, and there are several successful cases; When it comes to recycling technology for waste silk or textiles, it has invested in Worn again, a UK start-up that has developed a lab-wide technique for recycling polyester-cotton blends.

Multi-party cooperation to promote the implementation of the "double carbon" goal

Green is the most beautiful background color describing the development results of the industry. Under the "double carbon" strategy, as an important field to promote carbon peak and carbon neutrality, China's textile and chemical fiber industry has been at the forefront of the world, and industry enterprises bear important missions and responsibilities in the process of implementing the goal of carbon peak and carbon neutrality.

At the meeting, China Chemical Fiber Industry Association launched two new activities to promote the implementation of the "double carbon" goal: First, China Chemical Fiber Industry Association · Jiangsu Ruibang Technology Co., LTD. · China Fiber Zero Carbon Action (referred to as Ruibang · China Fiber Zero Carbon Action) framework agreement signing, the second is the launch of a credible platform for green fiber products.

Ruibang · China Fiber zero carbon action framework agreement signed

On the way to achieve the goal of "double carbon", industry enterprises need to have a clear understanding of it, a clear path and a means and platform for identification. Rui Bang · China Fiber Zero Carbon action is the textile and chemical fiber industry based on the national "3060" goal, through a series of creative, forward-looking, sustainable and effective work, guide the industry enterprises to abandon the traditional growth model, the application of innovative technology, innovative ideas and innovative mechanisms, take the initiative to explore sustainable low-carbon economic development mode, from many aspects to promote sustainable energy conservation and emission reduction. Finally promote the industry enterprises to achieve the "double carbon" goal. The specific work of the action includes the continuous holding of the China Fiber Zero Carbon Action Conference, the China Fiber Materials Sustainable Development Conference and the Textile industry Carbon Reduction path planning Forum, the "Carbon Reduction Plan" public welfare activities, and the regular writing and release of sustainable development reports.

Chen Xinwei, president of China Chemical Fiber Industry Association, and Zhang Yexing, general manager of Jiangsu Guowang High-tech Fiber Co., LTD., signed the framework agreement of "Ruibang • China Fiber Zero Carbon Action".

Jiangsu Ruibang Technology Co., LTD., the title unit of Ruibang · China Fiber Zero Carbon Action, is a subsidiary of Shenghong Group to lay out low-carbon green industry, and is an important link in the three industrial bases of Shenghong Group. Through independent research and development, Ruibang Technology took the lead in operating the world's first melt direct spinning device from bottle sheet to spinning, planning the construction of 500,000 tons of recycled fiber project, using waste plastic bottles as raw materials to produce high-quality polyester filament, providing customers with globally recognized and traceable types of recycled fibers. In October 2021, the 250,000-ton unit of Ruibang Technology Phase I was officially put into operation, which can consume 15 billion waste plastic bottles annually, equivalent to reducing 5.4 million tons of carbon dioxide emissions. In the future, Ruibang Technology will build a "global core supplier of recycled fiber" and jointly build a green industrial chain with upstream and downstream enterprises through China's fiber zero-carbon action.

Zhang Yexing, general manager of Jiangsu Guowang High-tech Fiber Co., LTD., said that in response to the national call of "carbon peak, carbon neutrality", Rui Bang Technology, a subsidiary of Shenghong Group, as an excellent green fiber enterprise in the industry, cooperated with China Chemical Fiber Association to launch China Zero carbon Fiber Action, hoping to contribute to the green development of the industry. In addition, since Shenghong Group invested in recycling fiber production in Siyang in 2019, it has begun to consider how to do green fiber and how to achieve green development.

Green fiber products trusted platform launch

At the meeting, the launch ceremony of the green fiber products trusted platform was held. The platform uses national secondary node analysis technology, blockchain technology, supply chain traceability system and other information means to build a transparent and reliable recycling traceability platform from bottle recycling to downstream clothing weaving, from fiber to end products, with the aim of creating China's own transparent, traceable and reliable industrial Internet platform. Maintain the order of the green fiber and textile market, and build this platform into a world-class certification platform in the future. On November 3, the Green Fiber Trusted Platform conference will be held in the Greater Bay Area International Textile & Yarn Expo (Shenzhen).

Gao Yong, Secretary of the Party Committee and Secretary General of China Textile Industry Federation, He Yaqiong, Director of the Department of Consumer Goods Industry of the Ministry of Industry and Information Technology, Duan Xiaoping, Vice president of China Textile Industry Federation, Jiang Shicheng, Academician of the Chinese Academy of Engineering, Chen Xinwei, President of China Chemical Fiber Industry Association, Huang Ping, Deputy Director of Jiangsu Provincial Department of Industry and Information Technology, Ma Wei, Secretary of the Party Committee of Siyang County, Jiangsu Guowang High-tech Fiber Co., LTD Zhang Yexing, general manager of the Department, and Mei Feng, chairman of the National Advanced Functional Fiber Innovation Center Co., LTD., witnessed the launch of the "Green Fiber Products Trusted platform Conference".

China Chemical Fiber Association Lyocell fiber branch was established

Lycel fiber is one of the representative products of green fiber, which quickly became a hot area of investment in the recycled cellulose fiber industry after industrialization during the "13th Five-Year Plan" period, and the industry capacity continued to grow. At the initiative of key enterprises in the industry, organized and prepared by China Chemical Fiber Association, Lycel Fiber Branch was formally established. Next, the Lyocell Fiber Branch will do a good job in maintaining the order of the Lyocell fiber industry and promoting the high-quality development of the industry.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

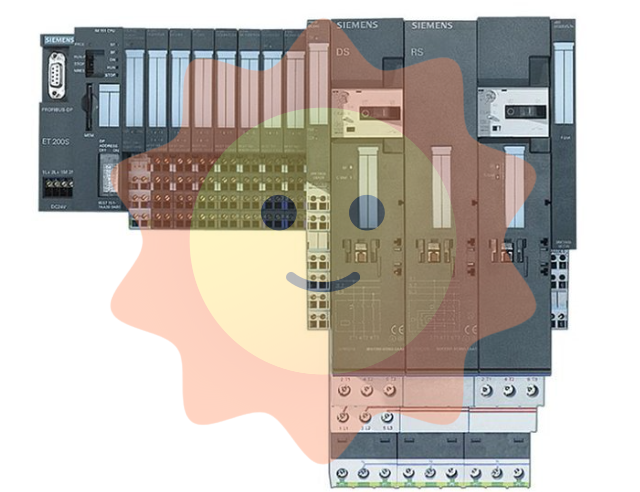

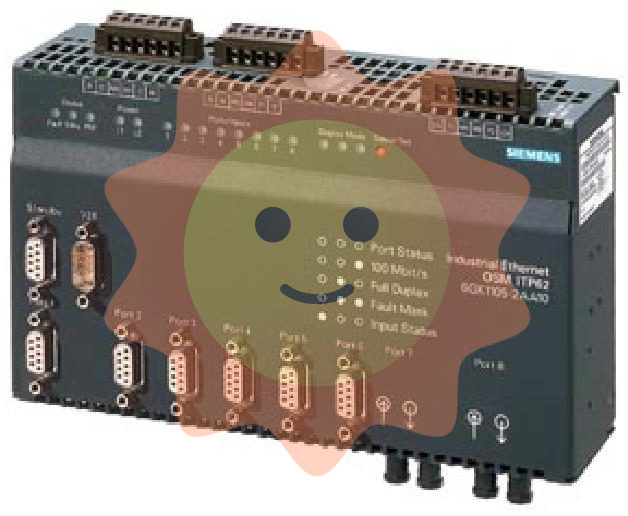

- Siemens

- Rockwell

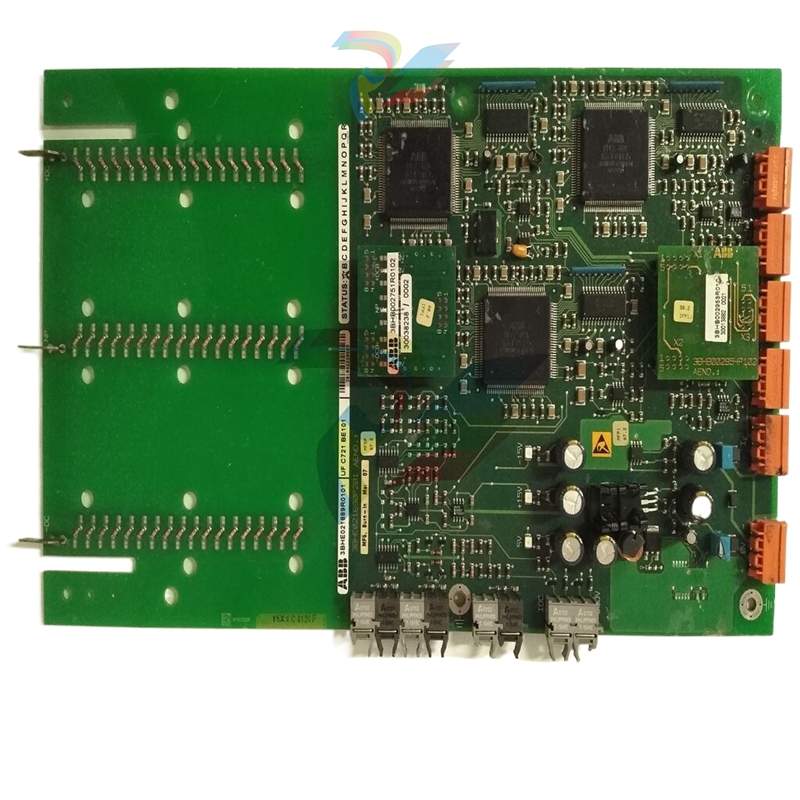

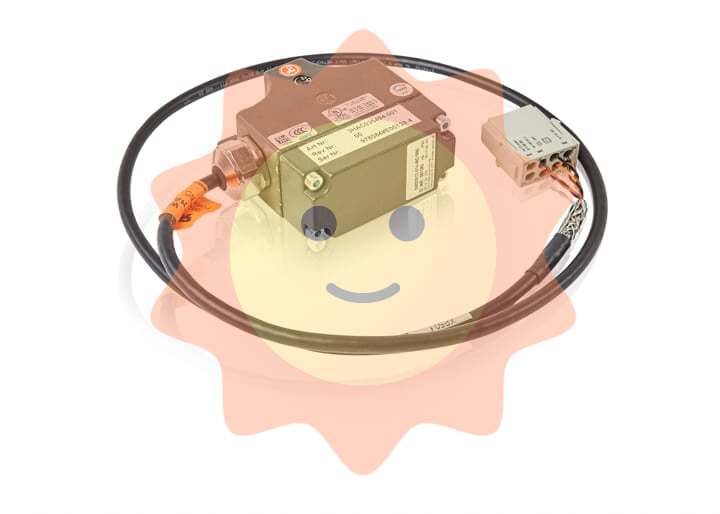

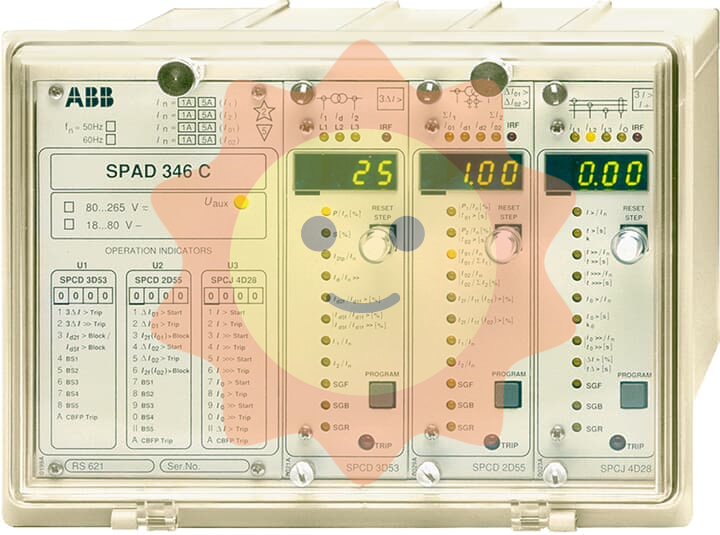

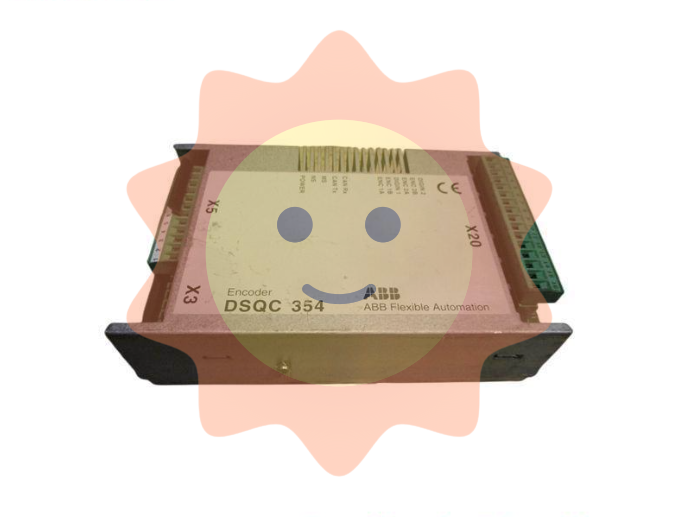

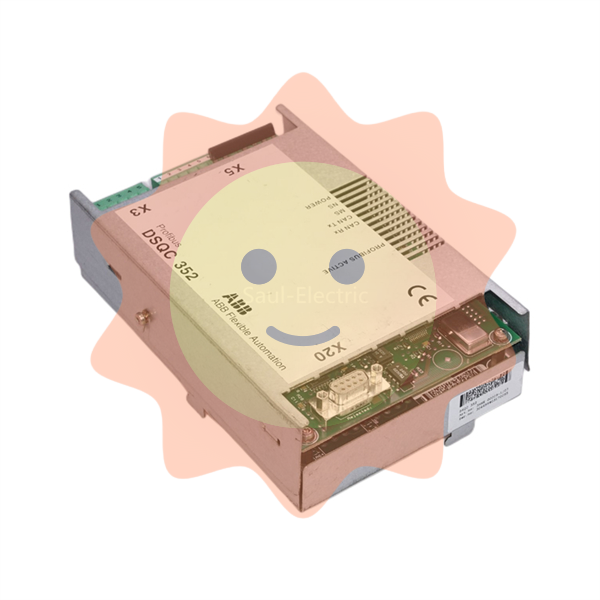

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

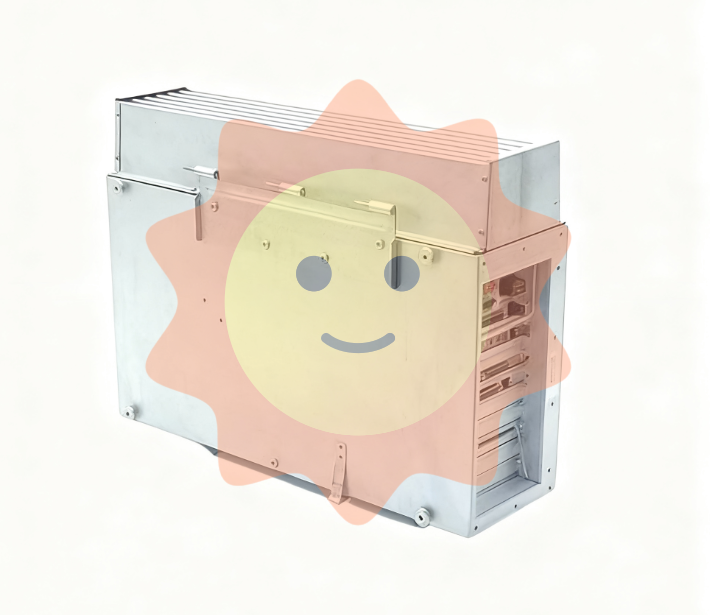

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

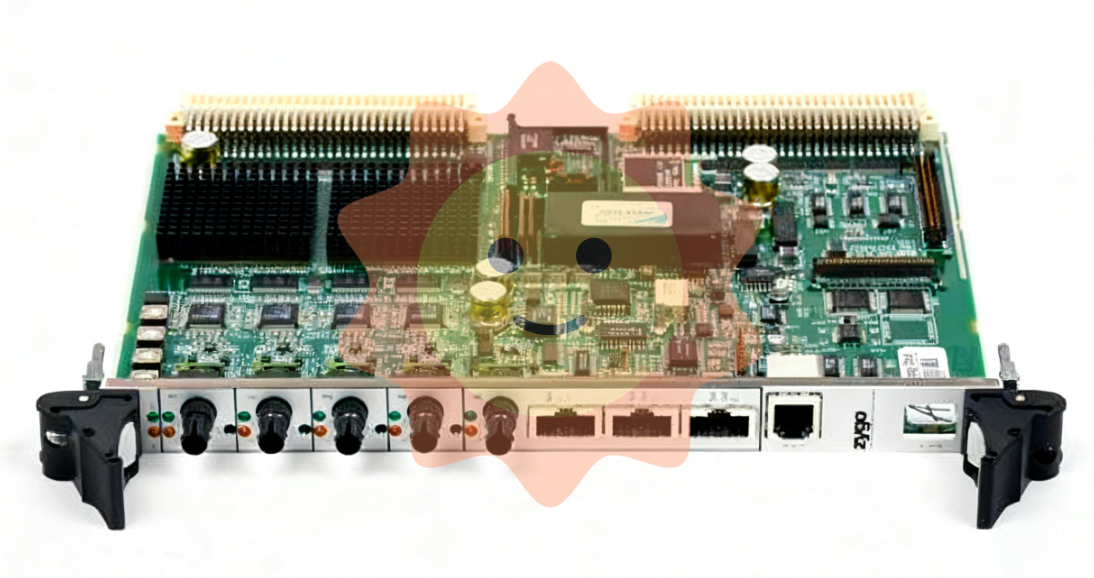

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

Email:wang@kongjiangauto.com