Honeywell Raeguard 2 PID gas detector

Honeywell Raeguard 2 PID gas detector

Product Overview

Raeguard 2 PID is a photoionization detection (PID) gas detector launched by Honeywell Analytics, mainly used for detecting volatile organic compounds (VOCs) and other ionizable gases. Its design is suitable for industrial safety, environmental monitoring and other scenarios, with features such as high precision, fast response, and easy installation and maintenance. It can be linked with control systems to achieve real-time monitoring and alarm of gas leaks.

Core functions and features

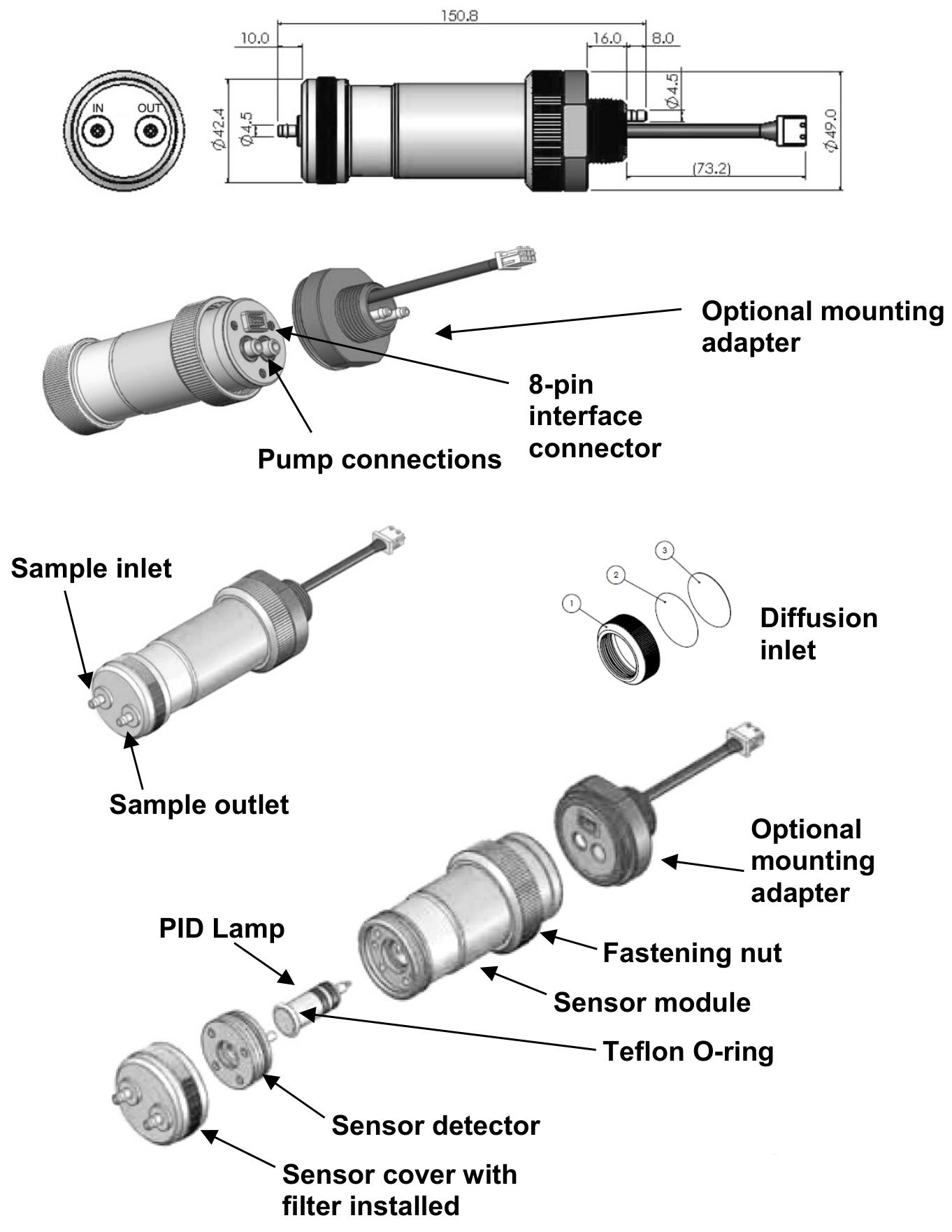

Detection principle: Using photoionization technology (PID), the energy generated by the ultraviolet lamp ionizes the target gas molecules, and the gas concentration is determined by measuring the ion flow intensity.

Applicable gases: covering most volatile organic compounds (such as benzene, toluene, formaldehyde, etc.) and some inorganic gases (such as ammonia, hydrogen sulfide, etc., to be confirmed according to specific models).

Performance advantages:

Wide range detection (usually 0-1000 ppm or customized range), high resolution;

Fast response and recovery time, suitable for real-time monitoring;

Support multiple output signals (such as 4-20 mA analog, relay alarm, RS485 digital communication, etc.) for easy system integration;

Built in self diagnostic function, which can monitor sensor status, circuit faults, etc., to ensure operational reliability.

Installation and setup

1. Installation preparation

Installation environment: Avoid direct exposure to extreme temperatures (usually operating at -20 ° C to+50 ° C), high humidity, dust, or corrosive gases; Stay away from strong electromagnetic interference sources such as motors and transformers.

Installation position: Select the installation height based on the specific gravity of the detected gas (heavier/lighter than air), ensuring that the sensor probe is located in an area where gas is prone to accumulate; Need to reserve maintenance space (such as replacing sensors, calibrating operations).

2. Wiring and Connection

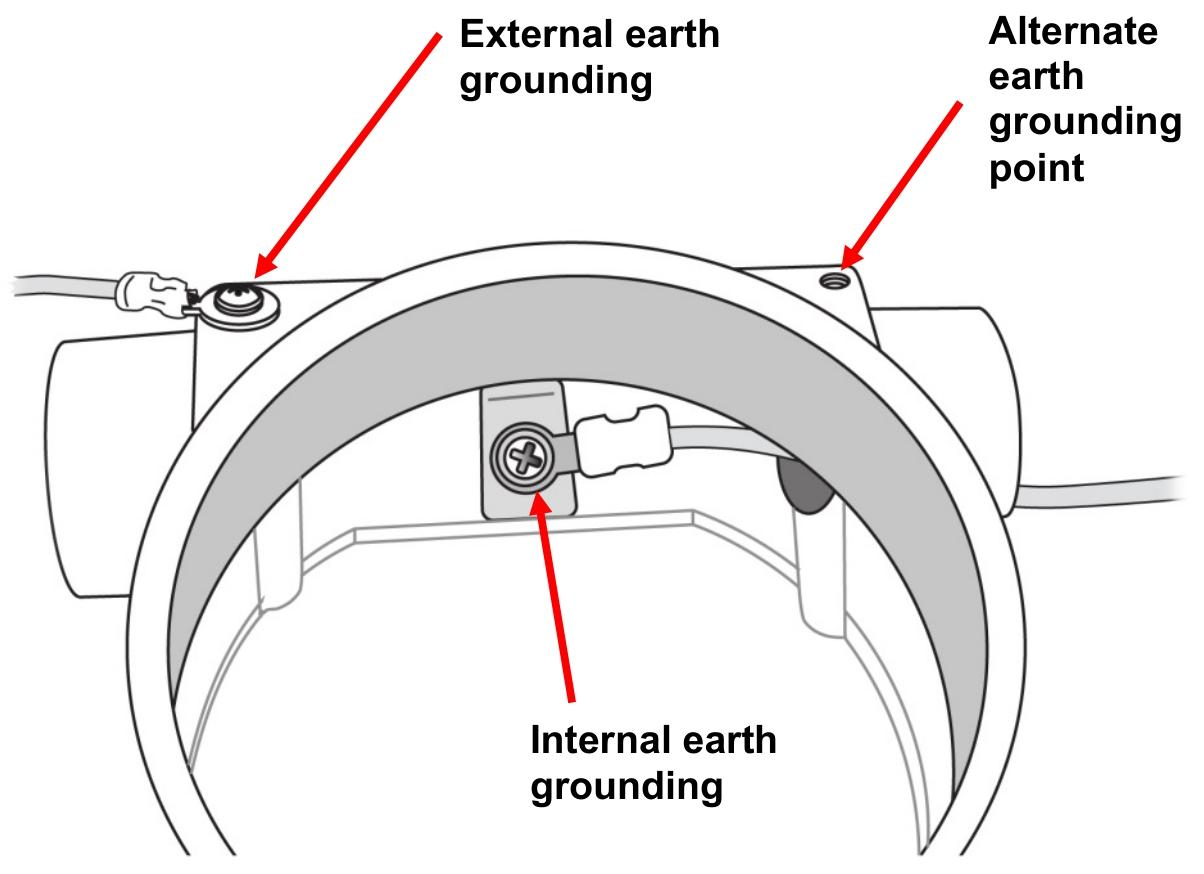

Power wiring: Usually powered by 24V DC, attention should be paid to positive and negative polarity;

Signal wiring: Connect to the controller, PLC, or alarm system according to the output type (e.g. 4-20 mA signal lines need to be shielded and grounded to avoid interference);

Terminal block instructions: including interfaces for power supply, signal output, alarm relay, etc., corresponding connections should be made according to the manual markings.

3. Initial setup

After power on, wait for preheating (usually a few minutes) to complete sensor stabilization;

Set alarm threshold (low alarm, high alarm), range, unit (ppm or mg/m ³) and other parameters through buttons or supporting software.

Operation and daily maintenance

1. Normal operation

Operation status indication: Check the device status through LED lights (such as green constant light indicating normal, red flashing indicating alarm, yellow indicating fault) or display screen (if any);

Data reading: transmit the output signal to the control system or view the display screen on site (supported by some models).

2. Calibration and verification

Calibration cycle: It is recommended to calibrate regularly (usually every 6 months) according to the usage environment to ensure detection accuracy;

Calibration steps:

Introduce zero air (such as clean air) for zero calibration;

Perform span calibration by introducing a standard gas of known concentration;

Verify the accuracy of the readings after calibration is completed.

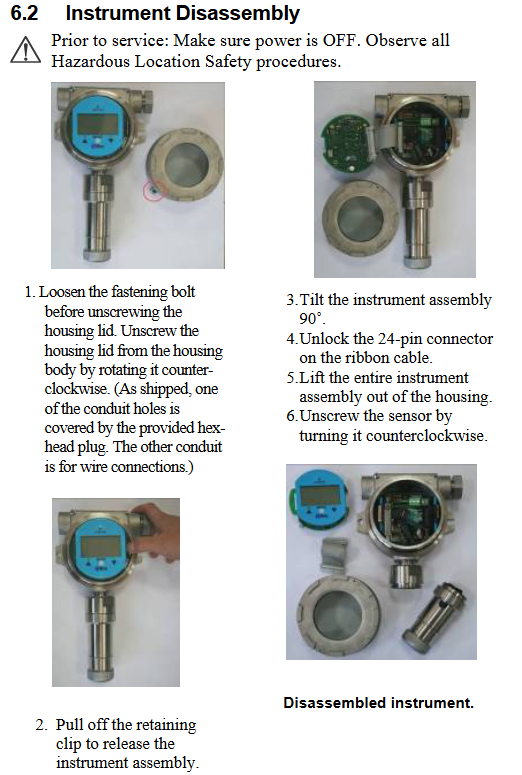

3. Maintenance and upkeep

Sensor maintenance: Regularly check the cleanliness of the sensor, and if the probe is contaminated, use specialized tools to clean it; Sensors have a service life (usually 1-2 years) and need to be replaced upon expiration;

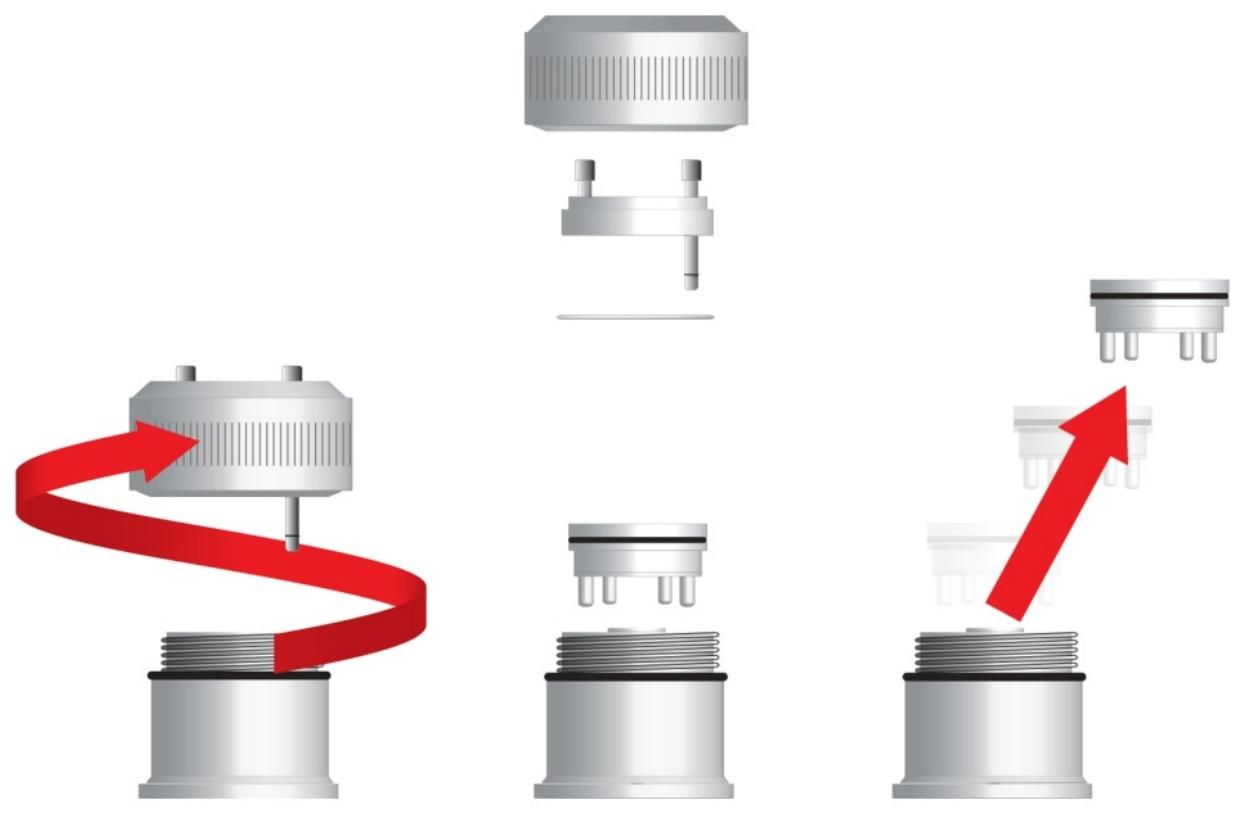

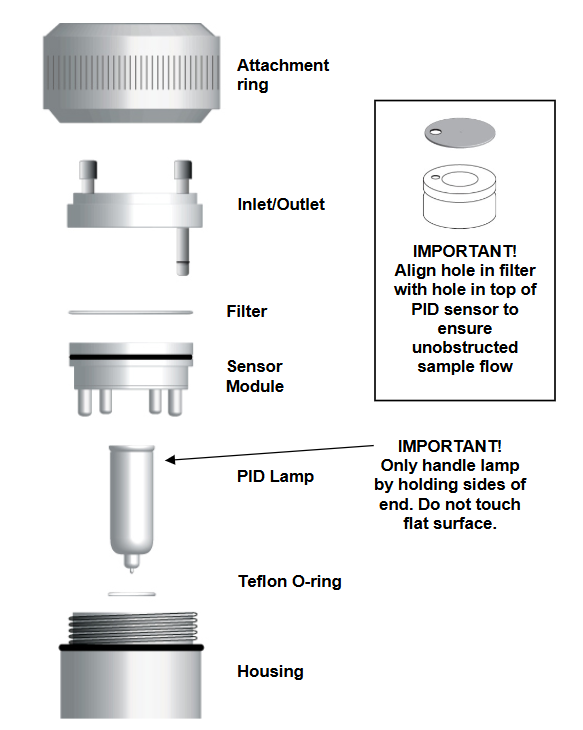

UV lamp maintenance: PID core components need to be replaced regularly (usually 1-2 years) according to manual requirements to avoid detection drift caused by lamp aging;

Shell and interface: Regularly check the sealing of the shell (protection level is usually IP66/IP67) to ensure that the wiring terminals are not corroded or loose.

Troubleshooting

Common faults and solutions (speculation):

No output signal: Check if the power supply is normal, if the wiring is loose, and if the fuse is blown;

Reading drift/inaccuracy: perform calibration; Check whether the sensor is expired or contaminated; Confirm the status of the UV lamp;

False alarm: Check for interfering gases (such as high concentration non target VOCs), calibration failure, or environmental humidity/temperature exceeding the range;

Fault light on: Read the fault code through the device's self diagnostic function or connection software, and troubleshoot the corresponding manual (such as sensor faults, circuit problems, etc.).

Safety and Compliance

Installation and maintenance should be carried out by professional personnel to avoid live working in explosive environments;

Must comply with relevant safety standards (such as ATEX, UL, IEC, etc., depending on the region and model);

Abandoned equipment should be disposed of in accordance with local environmental regulations to avoid environmental pollution caused by sensors or electronic components.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands