The GE MVR1600-4601 air-cooled rectifier module (hereinafter referred to as the "MVR1600-4601 module") is a high-performance power conversion equipment launched by General Electric (GE) for industrial power systems and new energy fields, designed specifically for medium to high power DC power supply scenarios. This module adopts advanced high-frequency switching power supply technology and intelligent air-cooled cooling solution, which can stably convert AC input into DC output that meets industrial standards, providing reliable DC power supply guarantee for key facilities such as communication base stations, data centers, industrial automation equipment, energy storage systems, etc.

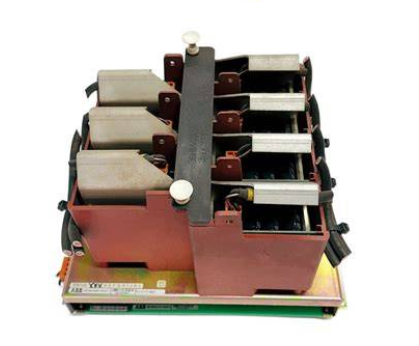

GE MVR1600-4601 air-cooled rectifier module

Product Overview

The GE MVR1600-4601 air-cooled rectifier module (hereinafter referred to as the "MVR1600-4601 module") is a high-performance power conversion equipment launched by General Electric (GE) for industrial power systems and new energy fields, designed specifically for medium to high power DC power supply scenarios. This module adopts advanced high-frequency switching power supply technology and intelligent air-cooled cooling solution, which can stably convert AC input into DC output that meets industrial standards, providing reliable DC power supply guarantee for key facilities such as communication base stations, data centers, industrial automation equipment, energy storage systems, etc.

Compared to traditional rectifier modules, MVR1600-4601 has significant advantages such as high conversion efficiency, accurate output accuracy, fast dynamic response, and low operation and maintenance costs. It has a built-in comprehensive protection mechanism and intelligent monitoring function, which can operate continuously and stably in complex power grid environments and harsh working conditions, effectively improving the reliability and economy of the entire power supply system. It is a core component of modern industrial and energy DC power supply systems.

Specification parameters

2.1 Electrical Parameters

-Product Model: GE MVR1600-4601

-Input voltage range: three-phase 380V~480V AC (line voltage), 50/60Hz adaptive

-Allowable fluctuation of input voltage: -20%~+15%

-Input current: ≤ 25A (per phase) at rated output

-Power factor (PF): ≥ 0.99 (under rated load conditions)

-Total harmonic distortion (THD): ≤ 5% (under rated load conditions)

-Output voltage range: 42V~58V DC continuously adjustable

-Rated output current: 35A

-Rated output power: 1600W

-Output voltage accuracy: ≤± 0.5% (under steady-state load conditions)

-Output ripple and noise: ≤ 100mVp-p (20Hz~20MHz bandwidth)

-Conversion efficiency: ≥ 96% (under rated input and output conditions)

-Output voltage regulation method: local potentiometer adjustment, remote communication control (RS485/Modbus protocol)

2.2 Environmental Parameters

-Working temperature: -20 ℃~+55 ℃ (After the ambient temperature exceeds 45 ℃, the output power linearly decreases, and at 55 ℃, it decreases to 70%)

-Storage temperature: -40 ℃~+85 ℃

-Relative humidity: 5%~95% (no condensation, temperature ≤ 40 ℃)

-Altitude: ≤ 2000m (After the altitude exceeds 2000m, the output power will decrease by 10% for every 1000m increase, with a maximum support of 5000m)

-Protection level: IP20 (indoor installation, well ventilated environment)

-Electromagnetic compatibility (EMC): Complies with EN 55032 Class B, IEC 61000-4-2/3/4/5/6 standards

2.3 Physical and Thermal Parameters

-Dimensions (length x width x height): 482.6mm x 132mm x 177mm (compatible with 19 inch standard cabinets, 2U height)

-Weight: Approximately 8.5kg

-Cooling method: Intelligent temperature control air cooling, backward centrifugal fan, wind speed automatically adjusted with load and temperature

-Fan lifespan: ≥ 50000 hours (at 25 ℃ ambient temperature and rated load conditions)

-Noise level: ≤ 55dB (at a distance of 1m, under rated load conditions)

Performance characteristics

3.1 Efficient and energy-saving, green and environmentally friendly

The module adopts full bridge phase-shifting soft switching technology, which significantly reduces switching losses and achieves a conversion efficiency of over 96% under rated operating conditions, effectively reducing energy waste. At the same time, its input power factor is ≥ 0.99, total harmonic distortion is ≤ 5%, it has low pollution to the power grid, meets the standards of green energy equipment, can reduce reactive power loss and line loss of the power supply system, and improve overall energy utilization efficiency.

3.2 Stable output and excellent accuracy

By using high-precision feedback regulation circuits and digital control chips, the output voltage accuracy of the module is controlled within ± 0.5%. Even in the case of input voltage fluctuations (-20%~+15%) or load changes (10%~100%), the output voltage can still remain stable. The output ripple and noise are ≤ 100mVp-p, which can meet the requirements of precision equipment with strict power supply quality requirements and avoid the impact of power supply fluctuations on equipment operation accuracy.

3.3 Intelligent heat dissipation, high reliability

Adopting an intelligent temperature controlled air cooling system, the fan speed is automatically adjusted according to the internal temperature and load situation of the module, reducing the fan speed in light load or low temperature environments to reduce noise and power consumption; Increase the speed in heavy-duty or high-temperature environments to ensure effective heat dissipation. This design not only extends the service life of the fan (≥ 50000 hours), but also avoids energy waste and noise problems caused by traditional fixed speed fans, while ensuring stable operation of the module in a wide temperature environment.

3.4 Improve protection, ensure safety and worry free

The module is equipped with multiple hardware and software protection mechanisms, including input overvoltage/undervoltage protection, output overvoltage/overcurrent/short circuit protection, over temperature protection, over power protection, fan fault protection, etc. When abnormal working conditions occur, the module can respond quickly (response time ≤ 10 μ s), protect itself and backend load equipment from damage through shutdown, current limiting, or alarm, etc. After troubleshooting, it can automatically resume operation (some faults require manual reset), improving the safety of system operation.

3.5 Flexible control, easy to integrate

Supports both local and remote dual control modes, and the output voltage can be accurately adjusted locally through the front panel potentiometer; Remote control can achieve output voltage regulation, working status monitoring, parameter configuration and other functions through RS485 interface and Modbus RTU protocol, making it easy to integrate into centralized power monitoring systems. At the same time, the module supports parallel operation of multiple units (up to 16 units) and has automatic current sharing function (current sharing error ≤ 3%), which can flexibly expand the system capacity according to actual power requirements.

3.6 Digital management, convenient operation and maintenance

Adopting a digital control architecture, the front panel is equipped with LED indicator lights (power light, running light, fault light, current sharing light) and a digital display screen, which can intuitively display key parameters and fault codes such as input voltage, output voltage, output current, module temperature, etc., making it easy to quickly troubleshoot problems on site. The remote monitoring system can collect real-time module operation data, achieve fault warning, historical data query, report generation and other functions, reduce operation and maintenance costs, and improve management efficiency.

Working principle

The core function of the MVR1600-4601 air-cooled rectifier module is to convert three-phase AC input into stable DC output. Its working process is mainly divided into four stages: AC input processing, power conversion, DC output regulation and control protection. Each stage works together to ensure the stability and reliability of the output power source.

4.1 Communication input processing stage

The three-phase 380V~480V AC input first passes through an EMI (electromagnetic interference) filter to filter out high-frequency interference signals in the power grid, while preventing interference generated inside the module from feedback to the power grid, meeting EMC standard requirements. Subsequently, the AC power is converted into pulsating DC power through a three-phase bridge rectifier circuit, and then smoothed and filtered through a filtering circuit composed of large capacity electrolytic capacitors to obtain a stable high-voltage DC bus voltage (approximately 530V~670V DC), providing stable input for the subsequent power conversion stage.

4.2 Power Conversion Stage

In this stage, a full bridge phase-shifting soft switching topology is adopted, and high-frequency driving signals are generated by a digital control chip (DSP) to control the conduction and turn off of four power switching transistors (IGBTs). By adjusting the conduction phase difference of the switching tube, high-frequency chopping of the high-voltage DC bus voltage is achieved, converting it into high-frequency pulse AC power. Subsequently, high-frequency pulsed AC power is isolated and stepped down through a high-frequency transformer to obtain high-frequency low-voltage pulsed AC power that meets the output requirements. At this stage, the soft switching technology significantly reduced the switching losses of the switching tube and improved the conversion efficiency of the module.

4.3 DC output regulation stage

High frequency and low-voltage pulse AC power is converted into pulsating DC power through a secondary rectification circuit (fast recovery diode), and then undergoes secondary smoothing filtering through an LC filtering circuit to filter out high-frequency ripples and obtain stable DC output. To ensure the accuracy and stability of the output voltage, the module has a built-in voltage feedback circuit that collects the output voltage signal in real time and transmits it to the DSP control chip. The DSP chip compares the collected voltage signal with a preset reference voltage, adjusts the driving signal of the power switch tube through PID algorithm based on the difference, changes the duty cycle or phase difference of the high-frequency chopper, and thus achieves precise adjustment of the output voltage.

4.4 Control and Protection Stage

The DSP control chip, as the "brain" of the module, is not only responsible for driving power conversion and adjusting output voltage, but also for real-time acquisition of various status signals such as input voltage, input current, output current, internal temperature of the module, and fan speed. When a signal exceeds the preset threshold (such as high input voltage, high output current, or high module temperature), the DSP chip immediately triggers the corresponding protection mechanism to quickly cut off the driving signal of the power switch or limit the output current. At the same time, the fault code is displayed through the LED indicator light and digital tube, and the fault information is uploaded to the remote monitoring system through the RS485 interface. After troubleshooting, the module can be restored to normal operation through manual or automatic reset.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-