The use of cement and matters needing attention

First, reasonable selection of cement varieties and strength grades

According to the construction site and engineering technical requirements, reasonable selection of cement types and strength grades to avoid improper selection of cement, resulting in project quality substandard or cost increase.

Second, pay attention to transportation and storage management

In the process of transportation and storage, avoid moisture and debris incorporation of cement, resulting in a decline in cement quality and performance. At the same time, be careful not to mix with organic substances such as sugar and fertilizer to avoid adverse reactions; The storage height of bagged cement should not exceed 20 bags, the palletizing is too high, and the lower cement is prone to buckling due to excessive pressure.

Third, can not be mixed

There are differences in the quality and performance of different varieties and strength grades of cement, which should be stacked separately and used separately, including cement of the same variety but from different manufacturers.

Fourth, strictly control the quality of mixed materials

Try to choose the sand with less mud content, the water used should not contain organic matter (sugar, fertilizer, washing supplies, etc.), in summer or winter preparation of concrete, pay attention to control the temperature of sand and water, to avoid the concrete setting time too fast or too slow.

Four, Cement construction ratio specification

For general civil buildings, the concrete-lime sand ratio is 1: 3, important parts such as beams, plates, columns, and foundation projects should be configured in accordance with the requirements of construction design specifications, mixing should be uniform during construction, the water-cement ratio should not be too large, vibration should be moderate, not over vibration, leakage vibration, not leakage slurry, continuous pouring, to avoid the uneven distribution of concrete cement, segregation, bleeding and other phenomena, so that the strength is reduced.

1 High Belite cement

The enthalpy of formation of C3S mineral in cement clinker is 1 810kJ/kg, while the enthalpy of formation of C2S mineral is only 1 350kJ/kg[2]. Therefore, increasing the content of C2S in clinker and reducing the content of C3S is an effective way to reduce the energy consumption of clinker calcination. Therefore, the low-calcium high-belite cement with C2S as the dominant mineral has become one of the most active research hotspots in the international cement industry.

The research of low heat Portland Cement system (C2S-C3S-C3A-C4AF, i.e., High Belite Cement) with Belite as the dominant mineral originated in the United States in the 1930s. It was during the construction of the 99m high Morris Dam in 1932-1935 that the first low-heat cement was developed, that is, limiting the content of C3A and C3S in the cement clinker to reduce the heat of hydration, which was the prototype of High Belite cement. Studies have also been conducted in Germany, Japan and Sweden. By the 1990s, China had achieved remarkable results in the research and practical application of high belite cement, and realized the industrial production of high performance and low heat Portland cement with C2S as the leading mineral for the first time at home and abroad.

The main difference in mineral composition between High Belite cement and general purpose Portland cement is the basic exchange of the content of two silicate minerals, C3S and C2S. High Belite cement is mainly composed of C2S with relatively low CaO content (C2S content is generally more than 45%), thus reducing the CaO content of the whole system. Its mineral composition is: C2S: 40% ~ 70%, C3S: 10% ~ 40%, C3A: 2% ~ 8%, C4AF: 10% ~ 25%[3]. Its mineral types are the same as general Portland cement, so its hydration process and hydration products are basically the same.

The raw materials used in High Belite cement are basically the same as those of traditional Portland cement, and admixtures such as gypsum, barite, pyrite, copper tailings and lead and zinc tailings need to be added to stabilize the highly active C2S crystal form [3]. High Belite cement has the characteristics of low resource and energy consumption, low environmental load and so on. If the firing temperature is only 1 350℃, about 100℃ lower than the traditional Portland cement, the emission of CO2 and SO2 during the firing process is reduced by 10%, and the cement performance has the characteristics of low heat and high late strength, which well meets the technical requirements of mass concrete, especially hydraulic concrete. It has also been applied in the world-renowned Three Gorges Dam and other key projects. But compared with traditional cement, high belite cement has the disadvantage of low early strength. To this end, cement researchers have made a lot of efforts to improve the early hydration activity of the high Belite system through various technical ways such as physical activation and chemical activation [4-8].

2 Aether Cement

Aether cement was developed and invented by Lafarge Company, and has declared the invention patent. Lafarge Cement established the Aether project team in 2010 and conducted research on Aether low carbon cement for three years (from September 1, 2010 to August 31, 2013). The Aether project team has completed two industrial tests of Aether cement production, confirming the feasibility of producing Aether cement on an industrial scale by relying on the existing cement kilns.

The raw materials available for Aether cement include limestone, bauxite, gypsum, iron raw materials and marl. Its introduction of calcium sulfoaluminate (C4A3S) mineral, production at a lower temperature (1 225 ~ 1 300℃), compared with Portland cement (1 400 ~ 1 500℃), can significantly reduce production energy consumption, tons of cement can reduce CO2 emissions by 25% ~ 30%. The mineral composition of Aether cement is: Belite (C2S) 40% ~ 75%, calcium sulfoaluminate (C4A3S) 15% ~ 35%, iron phase (C2(A, F)) 5% ~ 25%. Examples of Aether cement phase composition: C4A3S: 35.5%, β-C2S: 4.1%, α '-C2S: 44.0%, C12A7:0.7%, C2(A,F) : 12.4%, C2AS: 0.9%, CaSO4:2.4%.

Aether cement hydration process:

① C4A3S hydration:

C4A3S+2CS+38H→C3A·3CS·H32 +2AH3

② C2S starts to hydrate: C2S+AH3 +5H→C2ASH8

③ C2S hydration, C2(A,F) start hydration:

C2S+C2(A,F)+10H →C2(A,F)SH8+2CH

C2S + C2(A,F)+5H→C3(A,F)SH4+CH

④ Medium and long term hydration:

2C2S+C2(A,F)SH8 +(x-4)H→C3(A,F) SH4 +C3S2Hx

3 BCT cement

BCT cement, short for Belite-Calciumsulfoaluminate-Ternesite cement, was invented by Heidelberg Company in Germany and has applied for invention patent. Semi-industrial scale experiments were carried out using a test kiln with a diameter of 0.3m and a length of 7.6m, and several tons of BCT clinker with different compositions were produced. The whole production process (including discharge) of BCT cement clinker is similar to that of ordinary cement clinker, and the performance of BCT cement mortar produced is proved to be good. The next step will be to scale up to industrial scale and optimize manufacturing technology.

The core technology of BCT cement is the introduction of Ternesite in the clinker mineral system. Ternesite (C5S2S), consisting of 2 C2S and 1 CS, has always been considered inert, and studies have found that Ternesite is an active clinker mineral with a hydration reaction between aluminate and Belite. Unlike the traditional OPC clinker calcination process, which requires rapid cooling to retain the high reactivity of the clinker, the formation temperature of Ternesite is between 950 and 1 200 ° C, so the BCT clinker requires a slower cooling process or a relatively long residence time after the burning zone.

The raw materials required for BCT cement production are similar to ordinary Portland cement, and industrial waste residues such as limestone, marl, fly ash and industrial by-product gypsum are the raw materials. The introduction of calcium sulphoaluminate (C4A3S) and calcium sulphosilicite (C5S2S) in BCT cement clinker, produced at a lower temperature (1250 ~ 1300℃), CO2 emissions are 30% lower than traditional OPC cement clinker, and it is expected to save fuel and power consumption by 10% ~ 15%. The mineral composition of BCT cement clinker is: C5S2S: 5% ~ 75%, C2S: 1% ~ 80%, C4(AxF1-x)S: 5% ~ 70%, and secondary phases: 0 ~ 30%. (Patent protection scope) The best mineral composition is: C5S2S: 20% ~

0%, C2S: 20% ~ 50%, C4(AxF1-x)S: 20% ~ 45%, secondary phase: 10% ~ 20%.

x ranges from 0.1 to 1, preferably from 0.8 to 0.95.

4 Conclusion

In the clinker system of the above three types with low calcium minerals C2S and C4A3S as the dominant minerals, in addition to the high Belite cement of the silicate system, more than one low-energy, low-calcium, high-early-strength mineral is introduced into the cement of other systems, such as C4A3S, C5S2S and so on. High Belite content and the introduction of low calcium early strength minerals have become the trend of international low-carbon cement research.

However, from the study of Aether cement and BCT cement systems, C4A3S and C5S2S will decompose at 1 300℃. Therefore, the sintering range of cement clinker system introduced with this mineral is narrow, which puts forward higher requirements for process control level. In addition, too much introduction of the above low calcium early strength minerals into the system is not conducive to achieving high performance of the cement system. In terms of cement performance, although the cement of these systems has high early strength characteristics, it has corresponding adverse effects on construction performance and cement durability. For example, the setting process of the cement containing C4A3S system is difficult to control, so in most cases, it is only used as a special engineering material, limiting its wide application.

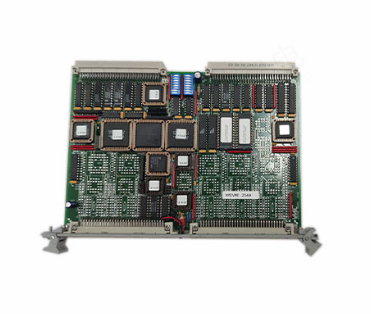

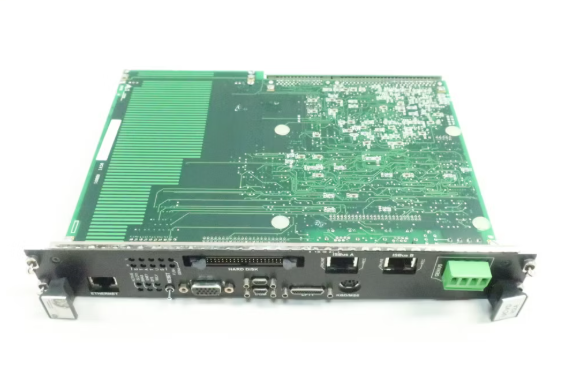

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com