Allen Bradley 1336 IMPACT AC Inverter

Allen Bradley 1336 IMPACT AC Inverter

Product Overview and Core Features

1. Product positioning and applicable scenarios

1336 IMPACT frequency converter is a microprocessor based field oriented control (FOC) AC frequency converter using Force technologies ™ Technology, focusing on low-cost independent applications, suitable for scenarios such as machine tools, production lines, and material handling that require precise speed regulation, supports speed and torque control of asynchronous motors, and is compatible with multiple feedback devices and communication protocols.

2. Core standard features

Performance and Control:

High precision digital speed loop and current loop, supporting 0-250Hz constant torque output, some configurations can achieve 400% motor current (short-term overload).

Supports multiple braking methods: dynamic braking, DC braking, magnetic flux braking, and bus voltage regulation, adapting to different load deceleration requirements.

Feedback and Interface:

Standard configuration includes 2 ± 10V analog inputs, 2 ± 10V analog outputs, and 1 4-20mA input/output. The 12 bit resolution ensures signal accuracy.

Support encoder feedback (requires L Option board), compatible with 12V/5V differential output encoder, up to 100kHz pulse input, achieving high-precision speed/position control.

Protection and reliability:

Built in motor overload protection (I ² T), inverter overload protection, overcurrent, overvoltage, undervoltage, ground fault, overheating and other multiple protections.

32 fault queues and 32 warning queues, with timestamps and fault markers for easy problem tracing; Non volatile memory (EE) stores parameters and configurations without loss during power outages.

Communication and Expansion:

Supports SCANPort communication and can connect to HIM (Human Interface Module), GPT (Graphics Programming Terminal), and 1203 series gateway modules (such as DeviceNet, RS-232/485).

Optional L Option board extension control input, supports TTL/24V AC/DC/115V AC interfaces, and some models come with encoder feedback interfaces.

Model Interpretation and Framework Classification

1. Model coding rules (taking 1336E-AQF05-AA-EN as an example)

Explanation of the meaning of digit codes

1-4 Position 1336E Product Series 1336 IMPACT AC Inverter

Position 5-6 AQ voltage level AQ=200-240VAC/310VDC; BR=380-480VAC/513-620VDC; CW=500-600VAC/775VDC

The rated power of F05 in positions 7-9 is 0.37kW (0.5HP); F07=0.56kW (0.75HP); F10=0.75kW (1HP), Repeat this process until 800C=597kW (800HP)

AA protection level AA=NEMA 1 (IP20) for positions 10-11; AE=NEMA 1 (IP20)/EMC (0.37-45kW dedicated); AF=NEMA 4 (IP65); AJ=NEMA 12 (IP54)

The 12th and 13th digits of EN language are English/English; FR=English/French; ES=English/Spanish; DE=English/German, etc

Subsequent mod options include HIM type (such as HA1 with analog potentiometer), communication module (such as GM5=DeviceNet), and L Option board (such as L8E=24V AC/DC+encoder)

2. Frame classification and power correspondence

The framework is divided by size and power, and the installation and wiring requirements for different frameworks are different. The core correspondence is as follows:

Framework Model 200-240V Power Range 380-480V Power Range 500-600V Power Range Key Features

A1 0.37-0.75kW (0.5-1HP) 0.37-1.2kW (0.5-1.5HP) - miniaturization, suitable for light loads

A2 1.2-1.5kW (1.5-2HP) 1.5-2.2kW (2-3HP) - Compact, supporting basic analog control

A3 2.2-3.7kW (3-5HP) 3.7kW (5HP) - Medium load, optional encoder feedback

A4-5.5-7.5kW (7.5-10HP) 0.75-7.5kW (1-10HP) with cooling fan, supporting dynamic braking

B 5.5-11kW (7.5-15HP) 15-22kW (20-30HP) 11-15kW (15-20HP) modular design, supporting multiple communication interfaces

C-H 30-75kW (40-100HP) 45-597kW (60-800HP) high power, requiring external reactors, H frame with independent cooling system

Installation and wiring specifications

1. General safety requirements

Static protection: The module contains ESD sensitive components, and a grounding wristband should be worn during operation. Refer to Rockwell document 8000-4.5.2 "Guidelines for Preventing Static Damage".

Power off operation: Before installation, all power sources of the frequency converter (including AC input, DC bus, control power) must be disconnected to avoid electric shock or component damage.

Cable requirements: Power cables must comply with NEC/VDE standards, and it is recommended to use shielded twisted pair cables (such as Belden 8760) for control cables to avoid parallel laying with high-power cables and reduce interference.

2. Key points for exclusive installation of the framework

(1) A1-A4 frame (low power)

Rail installation: Suitable for 35 × 7.5mm DIN rails, with hooks inserted and locked by rotation. The grounding resistance should be ≤ 2 Ω (detected through the metal shell of the RS-232 port).

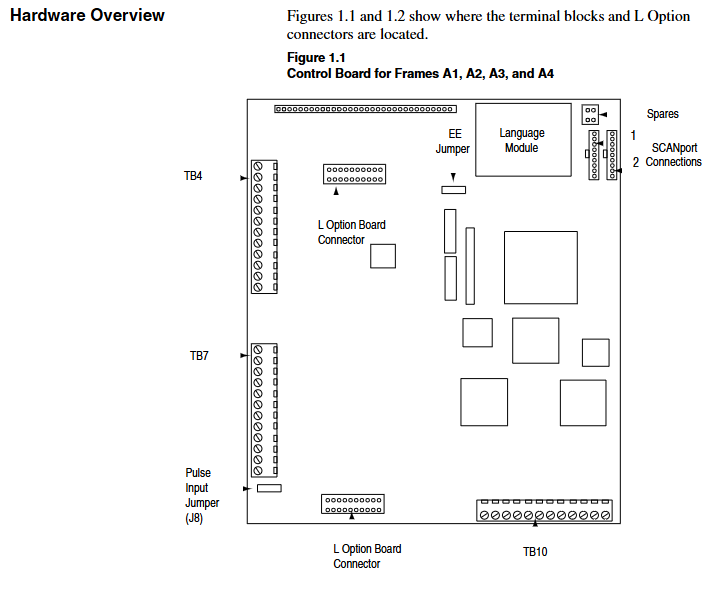

Wiring terminal: TB1 is the power terminal (R/L1, S/L2, T/L3 input; U/T1, V/T2, W/T3 outputs), TB4/TB7/TB10 are control terminals, supporting analog I/O, pulse input, and relay output.

Input protection: Users need to provide their own fuses. For example, models with 200-240V/0.37kW require 6A Class CC fuses (North America) or 6A gG fuses (Europe).

(2) B-H framework (high power)

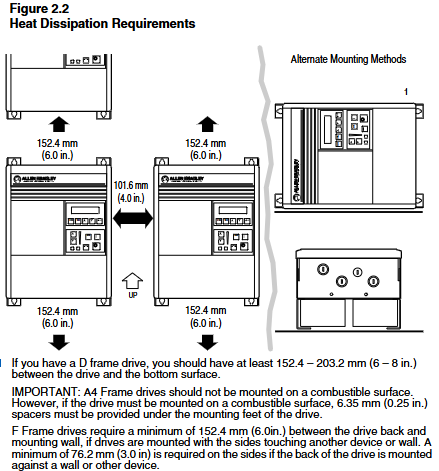

Fixed method: B-C frame can be installed on rails, D-H frame needs to be fixed with bolts, and reserved heat dissipation space (top/sides ≥ 152.4mm, bottom ≥ 101.6mm).

Wiring requirements: The D-H frame adopts bolt type terminals and requires dedicated wiring terminals (such as T&B COLOR KEYED) ®), The maximum wire diameter supported is 600MCM (253mm ²), and the torque must comply with the specifications (such as 23N · m for the H frame).

Cooling system: F-H frame with forced cooling fan, fan voltage needs to be confirmed (200-240V/380-480V), H frame needs independent air duct, air volume ≥ 2600CFM.

3. Key wiring specifications

Power wiring:

AC input: R/L1, S/L2, T/L3, requiring input fuses/circuit breakers (such as 140-MN-0250 circuit breaker for 380-480V/0.37kW).

Motor output: U/T1, V/T2, W/T3, cable length must meet the requirements (e.g. maximum 500m at 125Kbps, 100m at 500Kbps), and output reactors need to be added for long distances.

Control wiring:

Analog input: ± 10V input requires differential wiring, and the shielding layer is grounded at one end (TE terminal); 4-20mA input impedance of 130 Ω, maximum load of 750 Ω.

Encoder wiring (L Option board): A/A non, B/B non signal differential access,+12V power supply (maximum 200mA), shielding layer grounded.

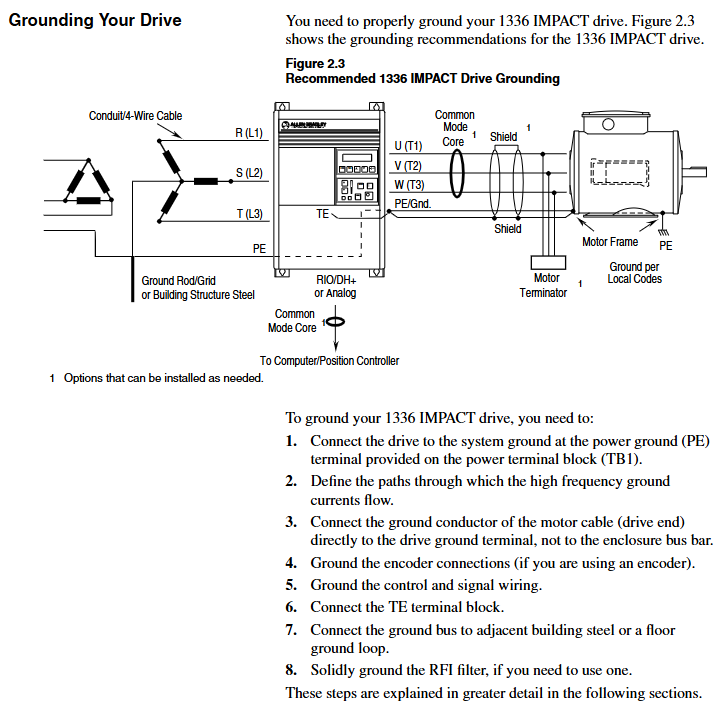

Grounding requirements:

The safety grounding (PE terminal) requires copper wire with a wire diameter of ≥ 1.5mm ² (16AWG) and a grounding impedance of ≤ 4 Ω.

The control signal grounding (TE terminal) is independent of the power grounding to avoid common ground interference.

System startup and parameter configuration

1. Preparation before startup

Hardware inspection: Confirm correct wiring (no AC input/output terminals, no short circuits), clean fan/heat sink, and securely install encoder (if any).

Tool preparation: HIM module (default connection to SCANPort 1), digital multimeter (measuring input voltage, within ± 10% of rated value), insulation resistance meter (measuring motor insulation, ≥ 1M Ω).

Parameter recording: Record the frequency converter model, motor nameplate data (power, voltage, current, speed, number of poles), and encoder PPR value for rapid debugging in the future.

2. Quick start process (via HIM)

(1) Power on and HIM operation

After powering on, the HIM displays the startup interface. Press any key to enter "Choose Mode" and select "Start Up".

Quick Motor Tune:

Select 'Enter Nameplate Motor Data' and enter the motor HP, voltage, current, etc Hz、 Speed and number of poles.

If using an encoder, select "Encoder" and enter the PPR value; Choose the braking method (dynamic braking/magnetic flux braking, etc.).

Press the START button to test the direction of motor rotation. If it is reversed, adjust the motor phase sequence; Run self-tuning (inductance, resistance, flux current, inertia test), and display "Tune Complete" after completion.

Config Digital Section:

Configure relay output (such as setting Relay 1 to "At Speed" and threshold to 95% rated speed).

Configure L Option mode (such as mode 5 supporting MOP manual potentiometer control) and stop type (coasting/ramp/current limit stop).

Configure Analog Section:

Link speed reference (e.g. Analog In1 link Speed Ref 1, Scale set to 2.0 to achieve ± 10V corresponding to ± 100% speed).

Configure analog output (such as Analog Out1 linked to Motor Speed, Scale set to 0.5 to achieve ± 100% speed corresponding to ± 5V output).

3. Core parameter description

Parameter classification, key parameter functions, and default values

Motor nameplate Nameplate HP (2) The rated power of the motor should be consistent with the nameplate

Motor Poles (7) motor pole count, default 4 poles

Speed control Speed Ref 1 (29) Main speed reference, default 0rpm

Accel Time 1 (42) acceleration time, default 5.0 seconds

Decel Time 1 (44) Deceleration time, default 5.0 seconds

Feedback and Protection Fdbk Device Type (64) Feedback Device Type, 0=No Encoder, 2=Encoder

Motor Overload% (26) motor overload threshold, default 115%

Communication and Expansion L Option Mode (116) L Option Working Mode, default 1 (disabled)

SP An In1 Select (133) SCANPort analog input selection, default 1 (HIM)

Functional applications and advanced controls

1. Basic control functions

Start stop and speed regulation:

Local control: Use the START/STOP button on HIM to start and stop, and the Up/Down button to adjust the speed; Remote control: Speed regulation through analog input (such as 4-20mA) or SCANPort signal.

Jog Speed 1 (38) is set to 10% rated speed, triggering Jog input to achieve jog control.

Braking control:

Dynamic braking: An external braking resistor is required, with Bus/Brake Options (13) set to bit10=1 and Regen Power Lim (76) set to 50% (adjusted according to the resistor capacity).

DC Braking: The DC Brake Current (79) is set to 30% of the rated current, and the DC Brake Time (80) is set to 2 seconds, suitable for rapid shutdown.

2. Advanced functional applications

(1) Speed Profiling

Function: Implement multi-stage speed control through 16 programmable steps, supporting switching between time, encoder counting, and digital input trigger steps.

Configuration: L Option mode 31/32 is required, with Step Speed (e.g. Step 1=400rpm), Step Type (1=time triggered, 3=encoder triggered), Step Value (e.g. 10 seconds/1000 counts) set, and End Action set to "loop" or "zero".

(2) Torque control

Function: Switch to torque mode (Spd/Trq Mode Sel (68)=1), set torque reference (0-100% rated torque) through Torque Ref 1 (69).

Application: Suitable for winding and tension control scenarios, requiring encoder feedback to ensure torque accuracy, Pos/Neg Torque Lim (74/75) limits maximum torque.

(3) Flying Start

Function: Start the frequency converter when the motor rotates to avoid current shock, suitable for restarting fans and pumps after sudden power failure.

Configuration: FStart Select (216)=2, FStart Speed (217) is set to the estimated speed (such as 800rpm), and the frequency converter automatically searches and synchronizes the speed after startup.

3. Communication configuration (SCAnport/DeviceNet)

SCAnport communication:

Supports up to 6 SCAnport devices, with HIM default to SCAnport 1 and gateway modules (such as 1203-GM5) connected to SCAnport 6.

Configure SP Enable Mask (124) to allow device control permissions, such as allowing SCANPort 2 to send start stop signals.

DeviceNet communication:

The 1203-GM5 card needs to be installed, and the node address (SW2-1~6, binary encoding) and baud rate (SW2-7~8, default 125Kbps) need to be set.

Create an EDS file through DeviceNet Manager, map I/O data (such as input=motor status, output=speed reference), and set the polling rate to 50ms.

Troubleshooting and LED diagnosis

1. Types of faults and solutions

Fault code, fault cause, and solution

Overvoltage: If the DC bus voltage is too high (such as the braking energy not being released), check if the braking resistor is damaged, increase the Regen Power Lim, and extend the deceleration time

Overcurrent motor short circuit, excessive load, parameter mismatch check motor insulation and wiring, reduce acceleration rate, and restart motor self-tuning

Ground Fault: The motor or cable is short circuited to the ground. Disconnect the motor to measure insulation and check if the cable shielding layer is poorly grounded

Encoder Fault: Encoder wiring error, signal interference check encoder power supply and differential signal, increase shielding layer grounding, reduce PWM frequency

Motor Overload: When the load exceeds the rated torque of the motor and the ambient temperature is too high, reduce the load, check the heat dissipation, and increase the Motor Overload% threshold (not exceeding 125%)

2. Interpretation of LED Status

The frequency converter contains 2 dual color LEDs (DeviceNet and SCAnport), and the status corresponds to the fault type:

Solution to the Meaning of LED Position Status

DeviceNet LED always on, red bus offline/address conflict troubleshooting, node address duplication, check terminal resistance (120 Ω), rewire

Flashing red I/O connection timeout reduces network load, confirms controller online, adjusts RPI (≤ 50ms)

SCANPort LED always on red link fault (no port recognition), disable unsupported Datalink, restart the frequency converter, and check the SCANPort cable

Flashing Orange Compatibility Test Failed Contact Rockwell Technical Support to Confirm HIM/Gateway Compatibility

Technical specifications

Project specification parameters

Input voltage 200-240VAC (± 10%), 380-480VAC (± 10%), 500-600VAC (± 10%), 3-phase 50/60Hz

Output voltage 0-input voltage, 3-phase PWM output, carrier frequency 1-16kHz (adjustable)

Control accuracy without encoder ± 0.5% rated speed, with encoder ± 0.1% rated speed

Working environment temperature 0-50 ℃, humidity 0-95%, no condensation, altitude ≤ 1000m (derating required for exceeding 1000m)

Protection level body NEMA 1 (IP20), optional NEMA 4 (IP65)/12 (IP54) (customized casing required)

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands