ABB PPD117A3011 (order number 3BHE030410R3011) is a high-performance core control unit developed by ABB for synchronous generator excitation systems. It is widely used in thermal power generation, hydropower generation, new energy supporting power generation, and industrial self owned power plants. This controller is based on ABB's mature excitation control technology platform, integrating high-precision signal processing, fast response control algorithms, and high reliability hardware design. It can accurately adjust the excitation current and terminal voltage of the generator, ensuring stable output of the generator under various operating conditions, and providing comprehensive protection functions for the generator. It is a key equipment to ensure the safe and efficient operation of the power generation system.

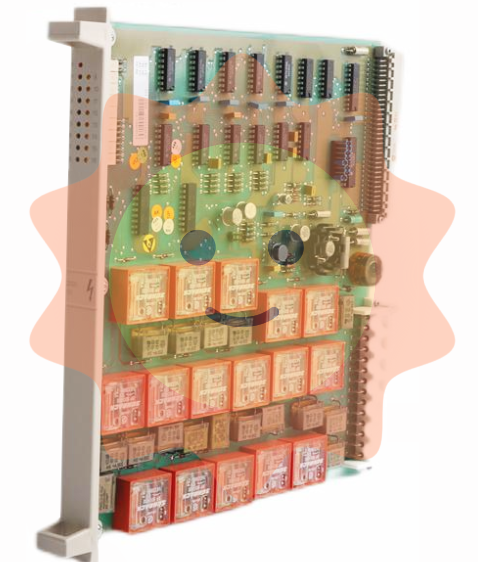

ABB PPD117A3011 3BHE030410R3011 Excitation Controller

Product Overview

ABB PPD117A3011 (order number 3BHE030410R3011) is a high-performance core control unit developed by ABB for synchronous generator excitation systems. It is widely used in thermal power generation, hydropower generation, new energy supporting power generation, and industrial self owned power plants. This controller is based on ABB's mature excitation control technology platform, integrating high-precision signal processing, fast response control algorithms, and high reliability hardware design. It can accurately adjust the excitation current and terminal voltage of the generator, ensuring stable output of the generator under various operating conditions, and providing comprehensive protection functions for the generator. It is a key equipment to ensure the safe and efficient operation of the power generation system.

As an important member of the ABB excitation system family, this controller is not only compatible with ABB's own excitation power units, but can also adapt to excitation devices from different manufacturers through flexible parameter configuration. It has strong universality and scalability, meeting the personalized application needs of different users.

Core functions and technical features

2.1 Core Control Functions

-Voltage regulation function: Using high-precision PID regulation algorithm, real-time collection of generator terminal voltage signal is carried out. After comparison and calculation with the set value, the output of the excitation power unit is accurately controlled to stabilize the generator terminal voltage within the allowable range. The voltage regulation accuracy can reach ± 0.2% of the rated voltage, effectively suppressing the impact of grid voltage fluctuations on the generator output.

-Excitation current control: It has an excitation current closed-loop control mode, which can quickly adjust the excitation current during generator start-up, load mutation, fault switching and other working conditions to ensure the stability of the generator magnetic field, avoid equipment damage caused by excessive or insufficient excitation current, and support smooth adjustment of excitation current to reduce the impact on the power grid.

-Reactive power regulation: By linking with the power grid dispatch system or unit coordination control system, the reactive power output of the generator can be automatically adjusted according to the reactive power demand of the power grid, achieving reasonable allocation of reactive power, improving the power factor of the power grid, reducing line losses, and enhancing the stability and economy of the power grid.

-Operating condition switching and fault-tolerant control: Supports disturbance free switching of multiple control modes such as "Automatic Voltage Regulation (AVR)" and "Manual Excitation Current Regulation (FCR)". When a control circuit fails, the system can quickly switch to the backup circuit to ensure uninterrupted excitation control; Simultaneously possessing the ability to configure redundant controllers, further enhancing system reliability.

2.2 Key Technical Features

-High reliability hardware design: using industrial grade high anti-interference components, the core processor uses high-performance embedded chips, with fast data processing capabilities and strong environmental adaptability; The hardware circuit adopts technologies such as optoelectronic isolation and surge suppression to effectively resist external interference such as electromagnetic interference and voltage surges, adapt to the complex electromagnetic environment of power plants, and have an average time between failures (MTBF) of over 100000 hours.

-Flexible communication and interaction capabilities: Supports multiple industrial communication protocols, such as Modbus, Profibus, Ethernet/IP, etc., and can easily connect to power plant distributed control systems (DCS) or monitoring information systems (SIS) to achieve remote monitoring of controller operation status, parameter settings, and data uploading; Equipped with an intuitive human-machine interaction interface (HMI), operators can complete parameter configuration, fault inquiry, and other operations through buttons or touch screens, making the operation convenient.

-Comprehensive protection function: Built in multiple protection logics such as over excitation protection, under excitation protection, excitation circuit overcurrent protection, and voltage abnormality protection. When abnormal working conditions are detected in the generator or excitation system, an alarm signal can be quickly issued or excitation cut-off action can be triggered to prevent the expansion of faults and protect the safety of key equipment such as generators and excitation transformers.

-Complete fault diagnosis and recording function: With real-time fault monitoring and diagnosis capabilities, it can accurately identify sensor faults, communication faults, hardware faults, etc., and issue alarm information through indicator lights, HMI interfaces, and communication interfaces; At the same time, it can record information such as the time of fault occurrence, fault type, and operating parameters at the time of fault, providing strong basis for fault troubleshooting and system maintenance.

Applicable scenarios and application advantages

3.1 Main Applicable Scenarios

This excitation controller is suitable for synchronous generators with a capacity range from tens of megawatts to hundreds of megawatts, and is widely used in the following fields:

-Thermal power plant: equipped with steam turbine generators to adapt to the frequent start stop and load changes of the unit, ensuring stable power generation.

-Hydroelectric power plant: In response to the large fluctuations in the speed of hydroelectric generators, voltage stability is ensured through rapid response control.

-New energy matching: used as a matching synchronous generator for wind power, photovoltaic and other new energy generation systems to enhance the stability of new energy grid connection.

-Industrial self owned power plants: provide reliable excitation control for self owned power plant generators in industries such as steel, chemical, and cement, ensuring stable electricity supply for enterprise production.

-Grid peak shaving unit: supports rapid reactive power regulation, meets the demand for grid peak shaving and frequency regulation, and enhances the resilience of the grid.

3.2 Application advantages

-Improving power generation efficiency: By precise excitation regulation, optimizing the operating conditions of the generator, reducing energy loss during the power generation process, and enhancing the power generation efficiency of the unit.

-Enhancing grid adaptability: Fast response speed and flexible adjustment capability enable generators to better adapt to fluctuations in grid voltage and frequency, improving the stability of grid connected operation.

-Reduce maintenance costs: The high reliability design reduces the frequency of equipment failures, the improved fault diagnosis function shortens maintenance time, and reduces equipment operation and maintenance costs.

-Compliant with industry standards: The product design complies with relevant domestic and international industry standards such as IEC and GB, and has passed strict performance testing and reliability certification, which can meet the application requirements of different regions.

Installation and maintenance precautions

4.1 Installation Requirements

-The installation environment should meet the conditions of temperature 0-55 ℃, relative humidity 10% -90% (no condensation), and avoid installation in environments with dust, corrosive gases, and strong electromagnetic radiation.

-The controller should be installed in a stable cabinet to ensure a secure installation and avoid vibration affecting equipment operation; The cabinet needs to have good ventilation and heat dissipation capabilities.

-When wiring, it is necessary to strictly follow the wiring diagram in the product manual to ensure that the power and signal cables are connected correctly and firmly. The signal cables and power cables should be laid separately to avoid interference.

4.2 Maintenance points

-Regularly check the operation status of the controller, including indicator lights, HMI display information, etc., to confirm that there are no abnormal alarms.

-Perform comprehensive maintenance on the controller every six months to one year, including cleaning the surface and internal dust of the equipment, checking the tightness of the wiring terminals, and testing the accuracy of key parameters.

-Regularly backup the parameter configuration files of the controller to avoid parameter loss due to equipment failure; If you need to update the firmware, you need to follow the process provided by ABB official.

-When the equipment malfunctions, the fault diagnosis information should be used to preliminarily locate the cause of the fault. If components need to be replaced, ABB original parts should be used to avoid using non original parts that may affect equipment performance.

- User name Member Level Quantity Specification Purchase Date

- Satisfaction :

-