Dead leaves, human waste and other biomass can actually generate electricity?

Common technology of biomass power generation

(1) turbogenerator

Electric energy is an important form of energy. Turbogenerators, which operate by burning fossil fuels and coal, are still the main way to generate electricity. Turbogenerators generate about 63.5 percent of the electricity used in the United States today, with 27.4 percent coming from coal and 35.1 percent from natural gas (based on 2018 data).

In recent years, the use of fossil fuels in conventional power plants has been decreasing due to increasing challenges to pollutant and greenhouse gas emission regulations. Globally, the number of ways to generate electricity from environmentally friendly renewable sources continues to increase, and the rapidly growing fields of sustainable energy generation include nuclear, wind, hydro and solar.

Biomass is a renewable resource, such as wood, grass, agricultural waste, animal and human waste, algae, etc. that is produced in large quantities in nature in a sustainable way in many parts of the world. According to reports, the United States produces approximately 1.3×109 t (dry base) of forest and agricultural waste per year, which is equivalent to 2×1012 kW·h of electricity generation (considering that the efficiency of thermal energy conversion to electricity is about 30%), about 50% of the electricity generation in the United States in 2014. Although the gasification or combustion of biomass combined with steam or gas turbines for power generation has been practiced commercially, total generation from biomass actually accounted for only 1.4 percent of the total electricity supply in the United States in 2018.

Generating electricity from biomass can be achieved in different ways. Direct burning of biomass is the most common method. Gasification, pyrolysis and anaerobic digestion are also used to produce biomass fuel that can be used as an energy source for steam turbines. During gasification, biomass is heated with less oxygen than is required for complete combustion, resulting in syngas. During pyrolysis, biomass is rapidly heated in the absence of oxygen to produce bio-oil. Anaerobic digestion of biomass relies on bacteria breaking down organic matter under hypoxic conditions to produce renewable natural gas.

A key challenge for biomass power generation is the difficulty of collecting and transporting biomass energy due to its low energy density. Most biomass plants actually operate at a loss. It is well known that ordinary biomass power plants are based on combustion after gasification or pyrolysis, which provides energy for steam turbines and generators. Due to the many operating units, biomass power plants are generally large in scale. In order to maintain stable daily operation, biomass power plants often require a large amount of biomass raw materials. Obviously, this is not economical. One possible solution is to reduce the size and cost of power plants to make biomass transportation viable and economical. At present, the problems of biomass power generation also include fuel procurement, transportation, storage and cost. The efficiency of a standard biomass power system is only about 20%. In the United States, the most common way to obtain heat from biomass is to burn biomass. The installation cost of small biomass power plants is $3,000 to $4,000 per kilowatt, and the energy cost is maintained at $0.80 to $0.15 per kilowatt-hour.

(2) High temperature biomass fuel cells

Biomass fuel cells are considered to be an emerging technology that can replace the use of combustion heat and gas turbines to generate electricity. Compared with heat engines that use fossil fuels, which convert thermal energy into mechanical energy and then into electricity, fuel cells are more attractive because of their superior performance and their ability to meet emerging environmental regulations. A fuel cell is a device that converts the chemical energy of a fuel into electricity and produces heat, water, and carbon dioxide (CO2) as a by-product. Indirect biomass fuel cell (IDBFC) and direct biomass fuel cell (DBFC) are two kinds of fuel cells with lignocellulose as energy source. With the development of fuel cell technology in recent years, IDBFC is able to first convert biomass into usable sugars (such as xylose and glucose), syngas, biogas and biochar, and then use these fuels for further power generation in fuel cells. IDBFC includes high-temperature fuel cells operating at temperatures up to 600 ° C, such as solid oxide fuel cells (SOFC) and direct carbon fuel cells (DCFC), as well as microbial fuel cells (MFC) operating at low temperatures. Compared with high temperature fuel cells, low temperature MFC is more efficient.

Compared with traditional power generation technology, SOFC is a power generation technology with good thermal and dynamic efficiency. The advantage of SOFC compared to other fuel cells is that it operates at high temperatures, makes better use of heat, and has a high tolerance to fuel gas composition and contaminants. Although the properties of different types of fuels (i.e., hydrocarbons) are different, they can all be used in such fuel cells. Potential SOFC fuels are natural gas, biogas, syngas from biomass/coal gasification, and hydrogen (H2). Traditionally, methanol has been the fuel of choice for most SOFC integrated systems. In recent years, lignin has been used as a fuel for SOFC and MFC for power generation. In SOFC, lignin is first converted into syngas by gasification and then further converted into electricity.

In SOFC, fuel oxidation occurs in the anode chamber. Oxygen is ionized in the cathode chamber and moves through the electrolyte to the anode chamber. In the anode chamber, the gas fuel is dispersed at the interface of the electrolyte and an electrochemical catalytic reaction occurs. Electrons in the fuel molecules travel through an external circuit to the other pole, generating electricity. The cathode receives electrons through an external circuit, reducing oxygen molecules and forming oxygen ions at the interface of the solid electrolyte. Oxygen ions move through the solid electrolyte to the anode and form either H2O or CO2, depending on the fuel type. The properties of the fuel cell electrolyte determine the operating temperature of the battery. In SOFC, the operating temperature is very high, close to the temperature of the gasification process. The higher operating temperature of SOFC makes it possible to combine biomass gasification technology with SOFC to improve power generation efficiency.

In recent years, there has been a focus on optimizing biomass gasification conditions and eliminating problems that arise during this process, including the formation of impurities such as ash, tar and other alkaline complexes. Compared with oxygen and air gasification, biomass vapor gasification coupled with SOFC can achieve maximum power generation efficiency. The entire energy conversion process has several performance indicators, including thermodynamic conversion efficiency, capital and operating costs, and environmental impact. The next step of research is to overcome the difficulty of material selection due to the properties of the materials, with the expectation that the properties of these materials can be clearly understood, thereby maximizing the power generation.

DBFC technology has recently been reported in the literature. This technology generates electricity directly from biomass without the need to pretreat or process the biomass to obtain liquid or gaseous fuel. In DBFC, different forms of lignocellulosic biomass, such as wood, grass, agricultural waste, algae, etc., can be converted into electricity. However, currently available DBFC technologies can only utilize refined biomass, such as starch or cellulose. There are still many shortcomings and challenges to be addressed in developing advanced power generation technologies that use fuel cells to convert biomass directly into electricity.

(3) Microbial fuel cells

In order to overcome the difficulties presented by traditional technologies, MFC has gained the attention of the scientific community in the past 10 years. This type of fuel cell can generate electricity from organic biomass. MFC is a heterogeneous reactor that uses microorganisms to convert organic compounds into electrical energy at low temperatures. In lignocellulosic biomass-based MFC, the biomass is first converted into fuels in the form of glucose, xylose, acetate, etc., for further oxidation reactions by microorganisms. The MFC consists of two electrolytic chambers, where two electrodes are separated by a semi-permeable membrane (proton exchange membrane (PEM) or anion exchange membrane (AEM)), and an external circuit. Microbial oxidation of fuel in anode chamber, typical products are CO2, protons and electrons. The electrons are captured by the anode and enter the cathode through the external circuit, while the protons on the anode enter the cathode through the membrane, and combine with the oxygen in the cathode and the electrons in the external circuit to form water. The potential difference between the cathode and the anode produces electrical energy. The microbes act as a "bridge" between the chemical and electrical energy of the fuel. In the process of oxidizing fuel into metabolites, the microbes in MFC gain energy by transferring the electrons produced in this process. However, in order to obtain a complete anode electron transfer mechanism, further investigation is needed.

In MFC, the substrate/fuel is the main factor affecting the entire process. Substrates used directly for MFC include pure cellulose and cellulose-rich feedstocks such as pre-treated corn stalks and seaweed. However, the complex structure of lignocellulose reduces the efficiency of power generation, resulting in lower electrical energy output. In order to improve the efficiency of MFC, the biomass needs to be pre-hydrolyzed to convert the biomass into soluble sugars, degraded phenolic compounds, acetic acid, furfural and 5-hydroxymethylfurfural (HMF) compounds. Prehydrolysis can produce different kinds of fermentable substrates from biomass. Glucose is one of the most important fuels extracted from biomass and is hydrolyzed from cellulose. Similarly, the hydrolysis of hemicellulose produces different pentose, hexose and acetic acid. These organic compounds show good power generation efficiency as carbon sources in MFC. Unlike the sugars in cellulose and hemicellulose, the phenols produced by lignin depolymerization have an inhibitory effect on microorganisms.

Although the concept of MFC has been around for a long time, industrial applications of MFC have been elusive. Limiting factors include the high cost, low yield, and limited durability of electrode materials and proton exchange membranes. The overall performance of an MFC depends on several factors, including: biolectation (i.e. reduced surface area due to blockage on the electrode surface), catalyst deactivation (if present), and excess biofilm growth. Excessive biofilm growth is due to the formation of non-conductive polymer fragments or dead cells, resulting in a decrease in the number of new generation biofilms. Other factors that lead to low MFC efficiency include electrocatalyst deactivation, fuel penetration from the anode chamber to the cathode chamber and vice versa, resulting in biofilm deactivation and mixed potential (i.e., system short circuit).

(4) The concept of low-temperature biomass liquid fuel cells

Fuel cells generate electricity from chemical energy, and their heat transfer efficiency is much higher than that of conventional turbo-driven generators. However, due to the lack of effective catalysts, biomass as a fuel for fuel cells is not yet possible. Recently, low-temperature fuel cells that convert biomass into electricity, with MFC as the main example, have been developed at operating temperatures below 100 ° C. At low temperature, its practical application is limited due to low efficiency and low power density. This article will highlight the latest advances in the use of fuel cells for power generation at low temperatures, and will also discuss the principles, advantages and disadvantages of FBFC.

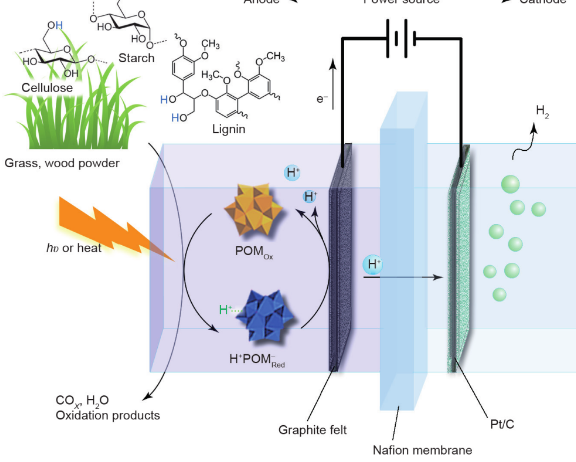

Great progress has been made in the research of fuel cells using small molecular organics such as methanol and formic acid. However, there was still a bottleneck in the development of low-temperature fuel cells using polymerized organic matter, until the new concept of liquid fuel cells (LFFC) was first reported by Liu et al. The solar-induced hybrid fuel cell reported by Liu et al. used phosphomolybdic acid (H3P-Mo12O40) as a photocatalyst for the anodizing of different types of biomass for the first time, as shown in Figure 1. Oxygen (O2) receives the final electrons in the Pt/C catalyst system at the cathode. When using cellulose as fuel, the solar-induced hybrid biomass fuel cell has a power density of 0.72 mW· cm-2, which is 100 times that of MFC using cellulosic fuel. In order to improve the efficiency of biomass liquid fuel cells, Liu et al. also built a precious metal free fuel cell using a polyoxometalate (POM) catalyst on the basis of previous studies. In this upgraded LFFC, they introduce POM (replacing the precious metal catalyst) into the cathode, which acts as an electron carrier, transferring electrons to oxygen, as shown in Figure 2. On this basis, the biomass oxidation reaction and oxygen reduction reaction are completed by using two different types of heteropoly acid solutions (H3P-W11MoO40 as the solution anode and H12P3Mo18V7O85 as the solution cathode). Such a cell structure can achieve a higher output power density even if untreated biomass is used as fuel. Using starch as fuel directly at 80 ℃, the battery can run continuously for more than 10 h, the battery power density is stable at 30 mW· cm-2, and the discharge current is 160 mA· cm-2. In direct biomass LFFC, various types of biomass, including cellulose, starch, wood meal and polyols, can be used as fuel. Due to the use of liquid catalysts instead of precious metal catalysts, fuel cells have a strong tolerance to organic and inorganic impurities and are less costly.

- ABB

- General Electric

- EMERSON

- Honeywell

- HIMA

- ALSTOM

- Rolls-Royce

- MOTOROLA

- Rockwell

- Siemens

- Woodward

- YOKOGAWA

- FOXBORO

- KOLLMORGEN

- MOOG

- KB

- YAMAHA

- BENDER

- TEKTRONIX

- Westinghouse

- AMAT

- AB

- XYCOM

- Yaskawa

- B&R

- Schneider

- Kongsberg

- NI

- WATLOW

- ProSoft

- SEW

- ADVANCED

- Reliance

- TRICONEX

- METSO

- MAN

- Advantest

- STUDER

- KONGSBERG

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- Beijer

- Moxa

- Rexroth

- Johnson

- WAGO

- TOSHIBA

- BMCM

- SMC

- HITACHI

- HIRSCHMANN

- Application field

- XP POWER

- CTI

- TRICON

- STOBER

- Thinklogical

- Horner Automation

- Meggitt

- Fanuc

- Baldor

- SHINKAWA

- Other Brands