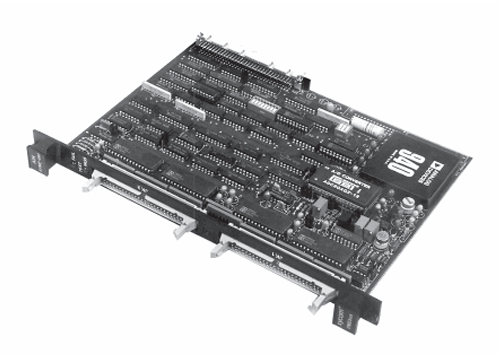

Xycom AIN XVME-560 Analog Input Module 70560-001

The XVME-560 can be programmed to operate in one of four operating modes: random channel, sequen tial channel, single-channel, or external-trigger mode.

After the completion of an A/D conversion, an optional interrupt may be generated.

The XVME-564 can sample unipolar and bipolar inputs, with voltage ranges of 0-5 V, 0-10 V, ±2.5 V,

±5 V, and ±10 V. Programmable gains of 1, 2, 4, or 8 may be software-selected.

Xycom AIN XVME-560 Analog Input Module 70560-001

Overview

The XVME-560 Analog Input Module is a powerful VMEbus-compatible analog input module capable of performing 12-bit A/D conversions on up to 64 different input channels.

The XVME-560 can be programmed to operate in one of four operating modes: random channel, sequen tial channel, single-channel, or external-trigger mode.

After the completion of an A/D conversion, an optional interrupt may be generated.

The XVME-564 can sample unipolar and bipolar inputs, with voltage ranges of 0-5 V, 0-10 V, ±2.5 V,

±5 V, and ±10 V. Programmable gains of 1, 2, 4, or 8 may be software-selected.

Features

• 64 single-ended or 32 differential channels

• 12-bit input resolution

• On-board DC/DC converter

• Jumper-selectable voltage ranges: 0-5 V,

0-10 V, ±2.5 V, ±5 V, and ±10 V

• Software-programmable gain: 1, 2, 4 or 8

• Can interrupt at any of seven VMEbus interrupt levels

Applications

• Slide wires

• Analytical equipment

• Microphones

• RTDs and thermistors

• Temperature transmitters

• Strain gauges and load cells

• Tach generators

Specification parameters

Number of channels: 16 single ended inputs or 8 differential inputs

Input signal range: Multiple selectable options including ± 10V, ± 5V, ± 2.5V, ± 1.25V, etc

Resolution: 12 bits

Sampling rate: up to 100kHz

Accuracy: ± 0.05% FSR (full range)

Isolation feature: There is photoelectric isolation between the channel and the system, with an isolation voltage of up to 1500Vrms

Data interface: Compliant with the VMEbus standard, easy to integrate into the VMEbus system

Power supply requirement:+5V DC, typical power consumption 1.5W

Working temperature range: 0 ℃ -55 ℃

Storage temperature range: -40 ℃ -85 ℃

Physical dimensions: Complies with VMEbus standard dimensions

Core functions

(1) Multi channel analog signal acquisition

Equipped with 16 single ended inputs or 8 differential input channels, capable of simultaneously collecting data from multiple analog signal sources. In industrial automation production lines, multiple types of sensors such as temperature sensors, pressure sensors, and flow sensors can be connected simultaneously to achieve real-time collection of key parameters such as temperature, pressure, and flow during the production process, providing a comprehensive data foundation for production monitoring and control.

(2) High precision signal conversion

A resolution of 12 bits and high precision of ± 0.05% FSR ensure accurate conversion of analog signals to digital signals. In scenarios such as scientific research experiment data collection and precision instrument measurement that require extremely high precision, the ability to accurately capture subtle changes in signals provides reliable data support for data analysis and decision-making, effectively avoiding data bias and decision-making errors caused by signal conversion errors.

(3) High speed sampling capability

With a sampling rate of up to 100kHz, it can quickly collect dynamically changing analog signals. In application scenarios such as motor control and vibration monitoring that require real-time tracking of rapidly changing signals, the latest status of the signals can be obtained in a timely manner, providing guarantees for rapid response and precise control of the system, and helping to improve the stability and reliability of equipment operation.

(4) Electrical isolation protection

1500Vrms optoelectronic isolation between channels and systems effectively isolates external interference signals, protecting modules and systems from electrical noise, overvoltage, and other factors. In complex industrial electromagnetic environments, it is possible to ensure the accuracy of data collection and the safe operation of modules, reduce the risk of system failures caused by electrical interference, and improve the stability of the entire industrial control system.

Working principle

The workflow of the Xycom AIN XVME-560 analog input module 70560-001 mainly includes four stages: signal input, conditioning, conversion, and output. When the analog signal from the sensor enters the module, it first goes through the input signal conditioning circuit. This circuit amplifies, filters, and adjusts the signal to a range suitable for A/D conversion based on the preset input signal range, while filtering out noise and interference components in the signal to improve signal quality.

After conditioning, the analog signal enters a 12 bit A/D converter, which converts continuous analog signals into discrete digital signals at a set sampling rate. During the conversion process, the analog signal is quantized and converted into binary digital codes, which represent the amplitude information of the analog signal.

After the converted digital signal is buffered and processed, it is transmitted to other devices in the VMEbus system, such as controllers and processors, through data interfaces that comply with the VMEbus standard. After receiving digital signals, these devices can further analyze, process, and store the data, thereby achieving monitoring and control of the physical quantities represented by analog signals.

Precautions

(1) Installation requirements

Before installing the module, it is essential to ensure that the VMEbus system is powered off to prevent electric shock and equipment damage. When installing, follow the instructions in the product manual to correctly insert the module into the VMEbus slot and ensure a secure connection to avoid abnormal data transmission caused by poor contact. At the same time, attention should be paid to the installation environment of the module, which should be kept dry and well ventilated, and avoid installation in environments with high temperature, humidity, dust or corrosive gases, so as not to affect the performance and service life of the module.

(2) Usage standards

During use, it is necessary to strictly set the input signal range and sampling rate parameters according to the specifications of the module to avoid exceeding the rated working range of the module and prevent module damage caused by overload or improper parameter settings. When connecting external devices such as sensors, ensure correct wiring, pay attention to signal polarity and electrical connection reliability, and prevent signal acquisition abnormalities or equipment failures caused by wiring errors.

(3) Maintenance and troubleshooting

Regularly inspect and maintain the module, including cleaning the dust on the surface of the module, checking for loose wiring, etc. If the module malfunctions, such as abnormal data collection or abnormal indicator lights, you can refer to the troubleshooting guide in the product manual for preliminary inspection and diagnosis. For more complex faults, it is recommended to contact Xycom's technical support personnel or professional maintenance personnel in a timely manner to avoid disassembling the module on your own and causing further damage

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com