Woodward MSLC-2 ™ Master Synchronizer and Load Control

MSLC-2 control combines synchronization, dead bus closure, utility/tie line load sensors, basic load control, inlet and outlet control, reactive power (VAR), power factor, and main process control in a powerful component.

Woodward MSLC-2 ™ Master Synchronizer and Load Control

Product description

Woodward's MSLC-2 ™ Compared to DSLC-2 ™ Control coordination can provide synchronization and load control between public utilities and contact circuit breakers. The MSLC-2/DCLC-2 combination operates through an Ethernet communication network and can control simple or complex generator system applications. This combination (32 DSLC-2 and 16 MSLC-2) provides multi unit, multi segment, utility, and tie line power management for complex power systems, while always providing non impact load transfer with utilities and controlling the import and export levels of the entire plant.

MSLC-2 control combines synchronization, dead bus closure, utility/tie line load sensors, basic load control, inlet and outlet control, reactive power (VAR), power factor, and main process control in a powerful component.

MSLC-2 provides phase matching, slip frequency synchronization, and voltage matching on utility or contact circuit breakers. The MSLC-2/DCSLC-2 combination can handle multiple utility connections, with a maximum of 8 bus segments in one application.

The load sensor and load control of MSLC-2 can detect true RMS power and provide shock free loading and unloading on the utility grid. Basic load, import and export, process and utility unloading modes control the kilowatt power between different power sources, while controlling reactive power, VAR and power factor. Reactive power will gradually increase and decrease to achieve the smoothest load trading between power grids.

MSLC-2 communicates via Ethernet (now providing redundant Ethernet) to control active and reactive loads for utilities through generators equipped with DSLC-2.

The contact circuit breaker mode allows synchronization between multiple generator systems. After connecting each section, power can be measured across the connecting line, but load control does not work when the connecting circuit breaker is in operation.

Product Features

One MSLC-2 can provide main control for up to 32 DSLCs and an additional 15 MSLC-2 in the system.

Two dedicated Ethernet lines are used for precise system communication between all DSLC-2 and MSLC-2 on the system.

Ethernet Modbus TCP, used for remote control and monitoring of PLC or DCS systems.

Redundant Ethernet communication improves reliability.

The main MSLC-2 is redundant, and communication loss with the designated MSLC-2 main device will initiate control switching to the next designated MSLC-2 main device.

MSLC-2 hardware can be adjusted for various applications.

Slip frequency or voltage phase matching synchronization is fully selectable, with dead bus options in both directions, providing ample flexibility for tie line and main tie line main applications.

Integrate functions into one device without connecting redundant sensors (such as PT, CT, and MOP) to various modules (such as load sensors and synchronizers).

Digital signal processing enables MSLC-2 to resist power line distortion and harmonics.

Three phase true RMS power detection can provide accurate readings even under unbalanced phase loads and voltage fluctuations.

Import and export control of multiple MSLC-2 public utilities in the same network segment.

Woodward ToolKit ™ The software allows for flexible settings using the same basic menu tree and overview screen as the original MSLC, without the need for a handheld programmer. The graphical overview and trend analysis of generator and bus parameters make MSLC-2 debugging more convenient.

Toolkit can be accessed through one of the Ethernet ports or the RS-232 port.

Phase angle compensation can adjust the additional deviation correction of the transformer.

The system update function allows for system reconfiguration.

Supports up to 32 generators, 16 main circuit breakers, and/or contact circuit breakers.

Can be configured for main circuit breaker and contact circuit breaker applications.

Complex applications with up to 8 bus segments.

Automatic segment recognition.

Redundant Ethernet communication improves reliability.

The 'System Update' function allows for system reconfiguration.

Compatible with PLC and DCS through Modbus RTU or Modbus TCP.

Automated factory loading and unloading to achieve impact free load transfer with utilities.

Control the import and export levels of the entire factory relative to public utilities.

Overall factory power factor control.

Ethernet or RS-232 port, used to configure devices using Woodward ToolKit software.

Has UL/cUL and CE certification.

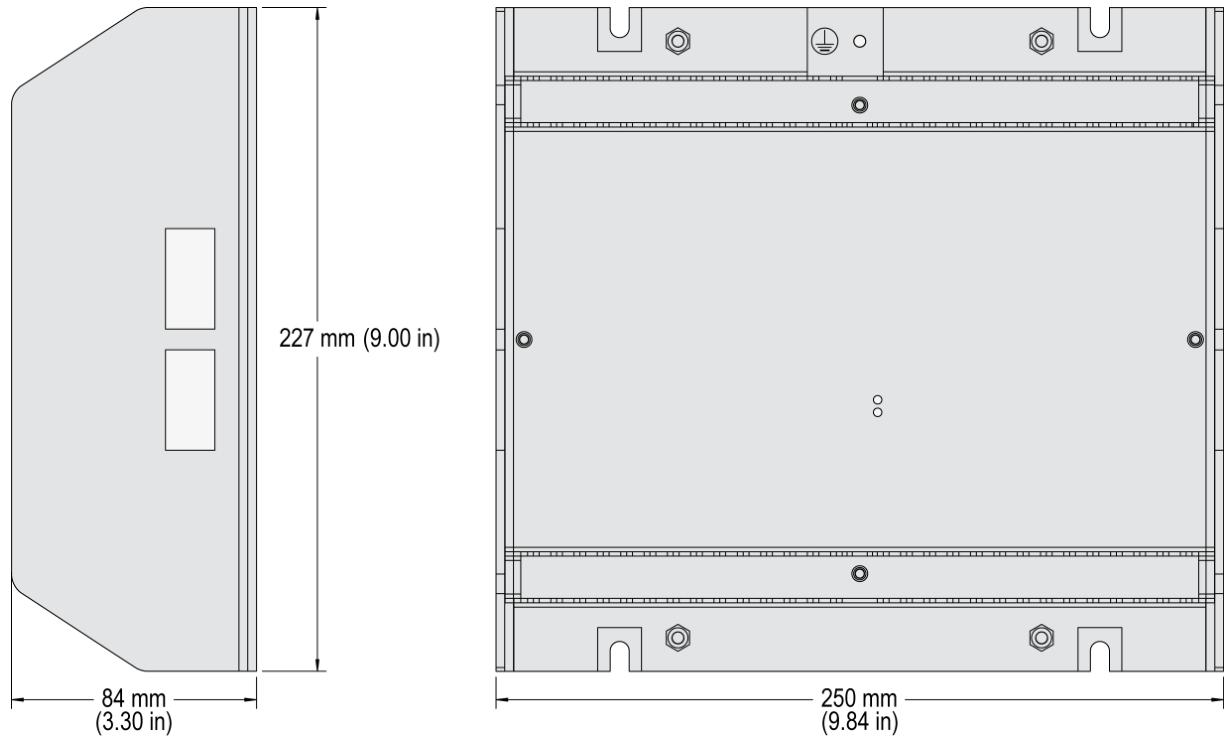

Technical specifications

Environmental condition

Storage environment temperature: -40 ° C to 85 ° C/-40 to 185 ° F.

Environmental humidity: 95%, non condensing.

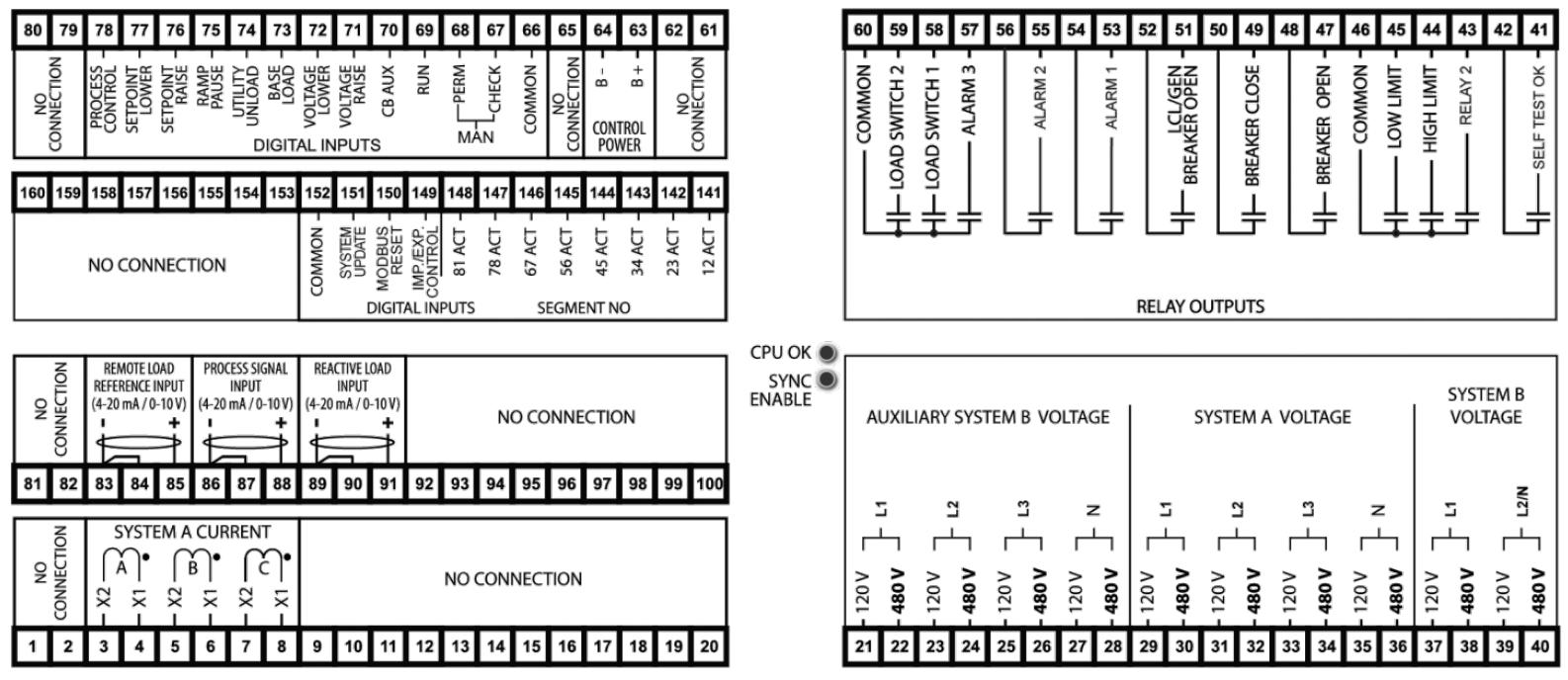

Electrical parameters

Relay output: 120 Vac [1] rated value (V rated) 69/120 Vac; Maximum value (Vmax) 86/150 Vac; Rated phase to ground voltage of 150 Vac; Rated surge voltage (V surge) 2.5 kV. 480 Vac [4] Rated value (V rating) 277/480 Vac; Maximum value (Vmax) 346/600 Vac; Rated phase to ground voltage of 300 Vac; Rated surge voltage (V surge) 4.0 kV.

Analog input (non isolated): accuracy level 0.5.

Measurable AC windings: 3p-3w, 3p-4w, 3p-4w OD.

Setting range: 50 to 650000 Vac on the primary side.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

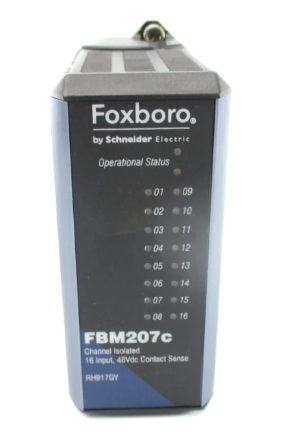

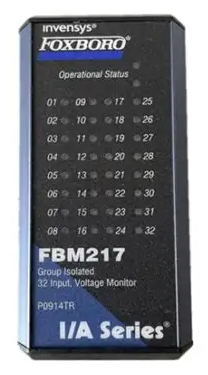

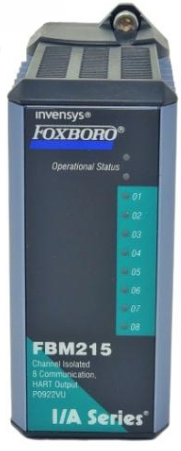

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

- BENDER

- BMCM

- SMC

Email:wang@kongjiangauto.com