Which areas do chemical plants contain and what are their roles?

Including the factory front area, administrative management area, public and auxiliary facilities area, machine repair storage area, process production equipment area, raw materials and finished products storage and transportation area, torch area, etc.

Factory front area: including office building, shift dormitory, canteen and other facilities. The function is to provide management supporting functions that are unrelated to production or have little relationship with production. It is generally arranged on the upwind side of the dominant wind direction, or on the downwind side of the minimum annual wind frequency, and is far away from the process production device area, raw material product storage and transportation area, and the torch area, and some enterprises also arrange the factory front area independently outside the factory.

Administrative management area: including central control room, general dispatching station, central laboratory, workshop office building, environmental protection testing station, etc. Its role is to provide direct control and management of the plant. The central control room is the control center of the whole plant. At present, the design and management concept of chemical plants tends to be unmanned in the device area. The control signals are all introduced into the central control room through the cabinets, and the control operation of the whole plant is realized in the central control room. Chemical laboratory for raw materials, finished products testing, to ensure that raw materials and product quality standards; The office building of the workshop is a place for the employees of each workshop to work and rest; The environmental monitoring station monitors the solid, liquid and gas emissions of the plant to ensure that the emissions meet the standards.

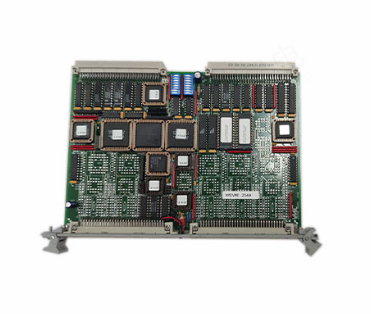

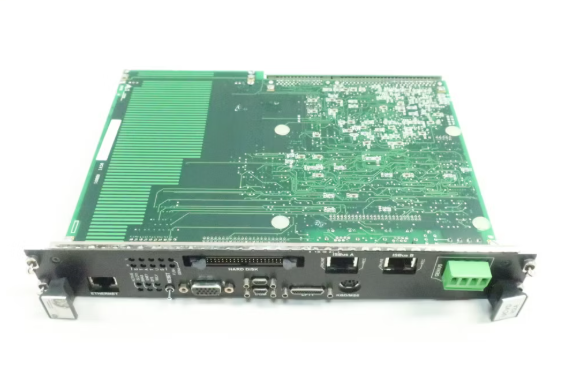

Public and auxiliary facilities area: including air separation, air compressed nitrogen station, boiler room, total buck station, transformer and distribution power station, cabinet room, fresh water fire water system, circulating water system, reclaimed water reuse system, sewage treatment system, etc. The full name of the utility auxiliary facilities area is to provide water, electricity, gas and steam for the factory and to provide conditions for production. Among them, the air separation and air compressor stations provide oxygen (as raw materials, to participate in chemical reactions) and nitrogen (to participate in reactions, or as instrument air) for the factory; Boiler room for the factory to provide steam, steam on the one hand can be used as a raw material to participate in the reaction, on the one hand can promote the steam turbine to produce power (because under normal circumstances, the use of steam drive than the cost of electric drive is much lower, so if conditions are available, chemical plants will generally use coal-fired boilers to produce steam, supporting various types of steam drive equipment operation); The total buck station and transformer station are the power supply system of the factory. The external power is first connected to the total buck by the high-voltage cable, and then the electric energy is transmitted to all parts of the factory through each transformer station. The cabinet is the supporting facility of the control system to realize the remote control of all kinds of equipment in the factory; Fresh water fire water system provides production, living and fire water source for the factory; The circulating water system uses water as the medium and the cooling tower as the equipment to cool all kinds of devices. Water reuse, sewage treatment system for production and domestic sewage treatment, after treatment part of the reuse, the rest of the discharge or evaporation crystallization.

Machine repair storage area: including all kinds of warehouses, storage yards, machine repair workshops. The function is to provide spare parts, catalysts, hazardous waste storage, and small equipment maintenance. All kinds of warehouses generally include spare parts warehouse, dangerous waste temporary storage warehouse, etc. The machine repair workshop is the mechanical and electrical instrument repair workshop.

Process production equipment area: contains all kinds of process production equipment. According to the different raw materials and finished products, the process equipment is various. It can be divided into petroleum chemical industry, coal chemical industry, natural gas chemical industry, etc. It is divided into large chemical industry and fine chemical industry according to scale. According to organic inorganic divided into organic chemical industry and inorganic chemical industry. It is used to produce chemical products by means of synthesis or separation.

Raw material product storage and transportation area: including gas storage tank, liquid tank area, car loading station, train loading station and other facilities. It is used for the storage and handling of raw material products. Due to the huge reserves of flammable liquid and flammable gas in this area, the impact of an accident is huge, so it is generally arranged in the corner of the factory, near the wall arrangement, and away from the factory front area and the administrative management area.

Torch area: The area where the torch is arranged. The torch includes an elevated torch and a ground torch, and large chemical plants generally use an elevated torch. In the case of accidents or normal maintenance, in order to ensure safety, the combustible gas and liquid in the pipeline and equipment are transported to the torch through the pipeline, which is a pressure relief discharge system.

- EMERSON

- Honeywell

- CTI

- Rolls-Royce

- General Electric

- Woodward

- Yaskawa

- xYCOM

- Motorola

- Siemens

- Rockwell

- ABB

- B&R

- HIMA

- Construction site

- electricity

- Automobile market

- PLC

- DCS

- Motor drivers

- VSD

- Implications

- cement

- CO2

- CEM

- methane

- Artificial intelligence

- Titanic

- Solar energy

- Hydrogen fuel cell

- Hydrogen and fuel cells

- Hydrogen and oxygen fuel cells

- tyre

- Chemical fiber

- dynamo

- corpuscle

- Pulp and paper

- printing

- fossil

- FANUC

- Food and beverage

- Life science

- Sewage treatment

- Personal care

- electricity

- boats

- infrastructure

- Automobile industry

- metallurgy

- Nuclear power generation

- Geothermal power generation

- Water and wastewater

- Infrastructure construction

- Mine hazard

- steel

- papermaking

- Natural gas industry

- Infrastructure construction

- Power and energy

- Rubber and plastic

- Renewable energy

- pharmacy

- mining

- Plastic industry

- Schneider

- Kongsberg

- NI

- Wind energy

- International petroleum

- International new energy network

- gas

- WATLOW

- ProSoft

- SEW

- wind

- ADVANCED

- Reliance

- YOKOGAWA

- TRICONEX

- FOXBORO

- METSO

- MAN

- Advantest

- ADVANCED

- ALSTOM

- Control Wave

- AB

- AMAT

- STUDER

- KONGSBERG

- MOTOROLA

- DANAHER MOTION

- Bently

- Galil

- EATON

- MOLEX

- Triconex

- DEIF

- B&W

- ZYGO

- Aerotech

- DANFOSS

- KOLLMORGEN

- Beijer

- Endress+Hauser

- MOOG

- KB

- Moxa

- Rexroth

- YAMAHA

- Johnson

- Westinghouse

- WAGO

- TOSHIBA

- TEKTRONIX

Email:wang@kongjiangauto.com